Simulative cutting experiment device for coal mining machine

An experimental device and shearer technology, applied in cutting machinery, earth-moving drilling, etc., can solve the problems of inability to control flow, difficult to adapt to high power and inertial loads, lack of experimental research, etc., and achieve the effect of convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

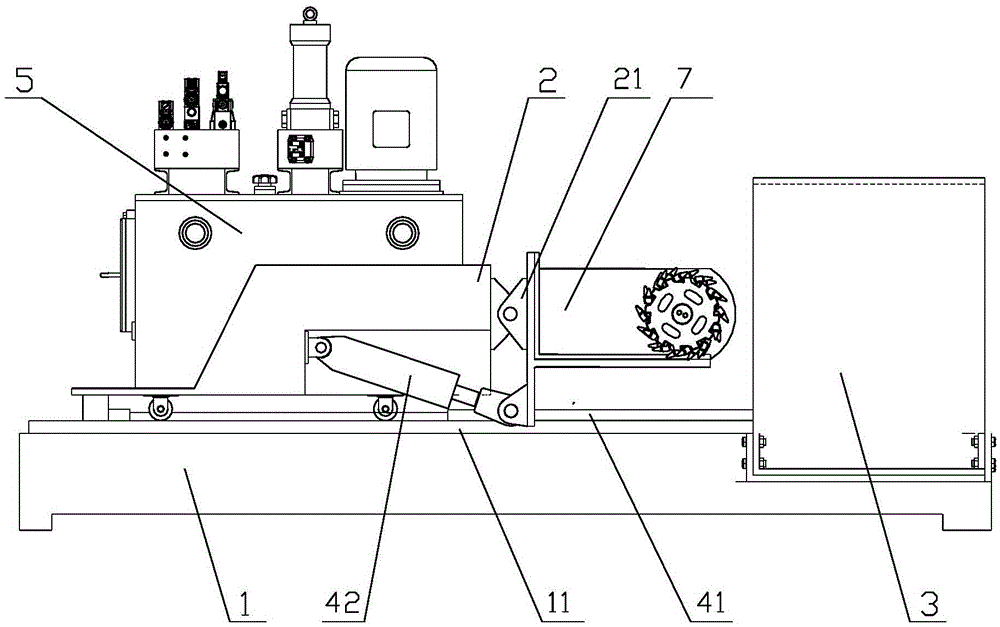

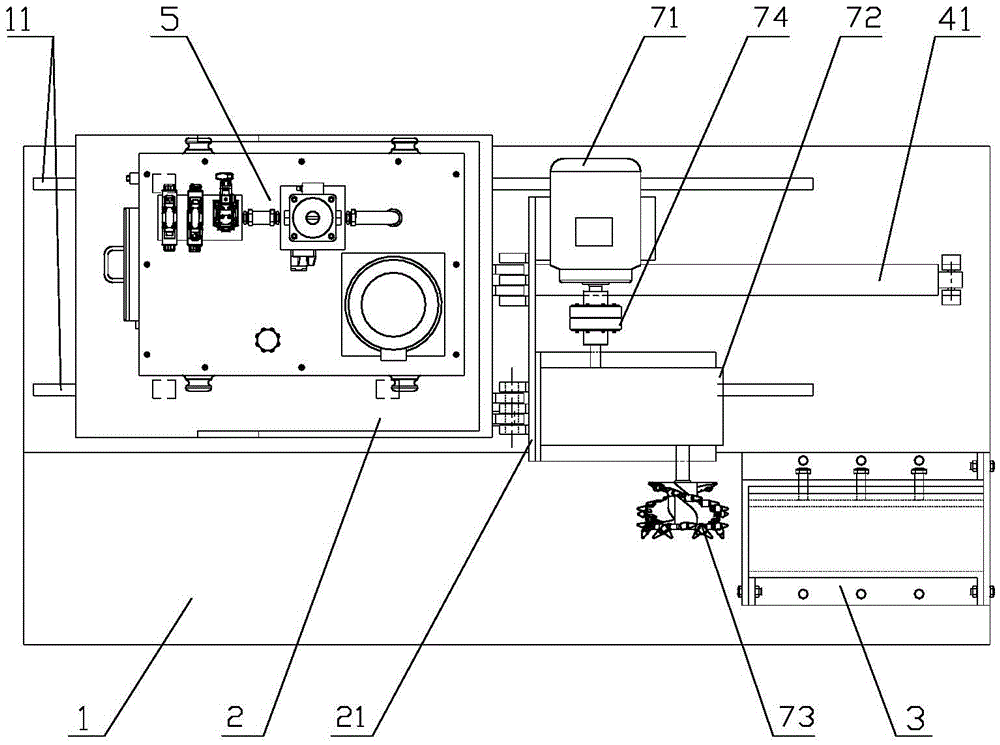

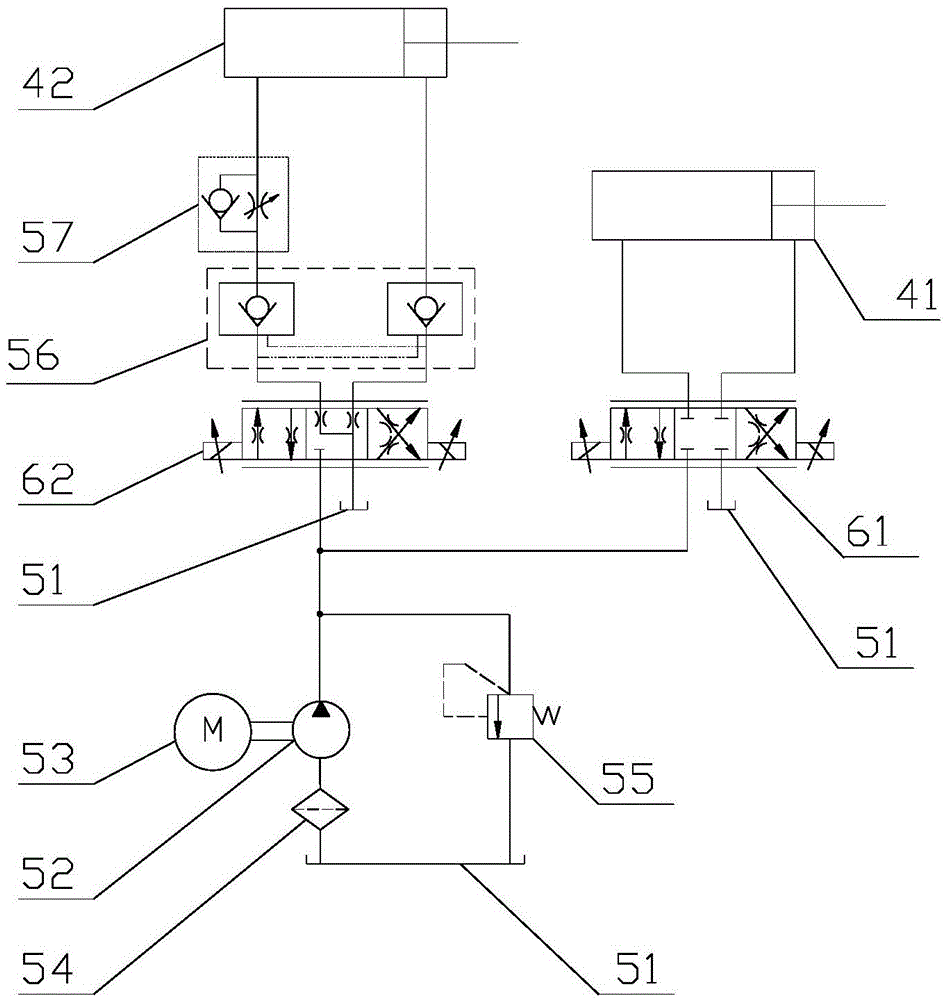

[0022] Such as Figures 1 to 4 as shown, figure 1 It is a structural schematic diagram of a shearer simulated cutting experimental device proposed by the present invention, figure 2 for figure 1 top view of image 3 for figure 1 The working principle diagram of the power mechanism, Figure 4 for figure 1 Schematic diagram of the structure of the simulated coal wall mechanism.

[0023] refer to Figures 1 to 4 , a shearer simulated cutting experimental device proposed by the present invention, comprising: a base 1, a fuselage 2, a cutting mechanism 7, a simulated coal wall mechanism 3, a first driving mechanism, a second driving mechanism, and a power mechanism 5;

[0024] The base 1 is provided with a track 11, the fuselage 2 is movably mounted on the track 11, the first driving mechanism adopts a first hydraulic cylinder 41, one end of the first hydraulic cylinder 41 is fixed on the base 1 and the other end is used with the fuselage 2 for The drive body 2 moves along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com