Intelligent simulation earthquake loading test box

A loading test and model box technology, applied in the field of geotechnical engineering, can solve the problems of sample structure damage, unsafe controllability, etc., and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail with reference to specific embodiments:

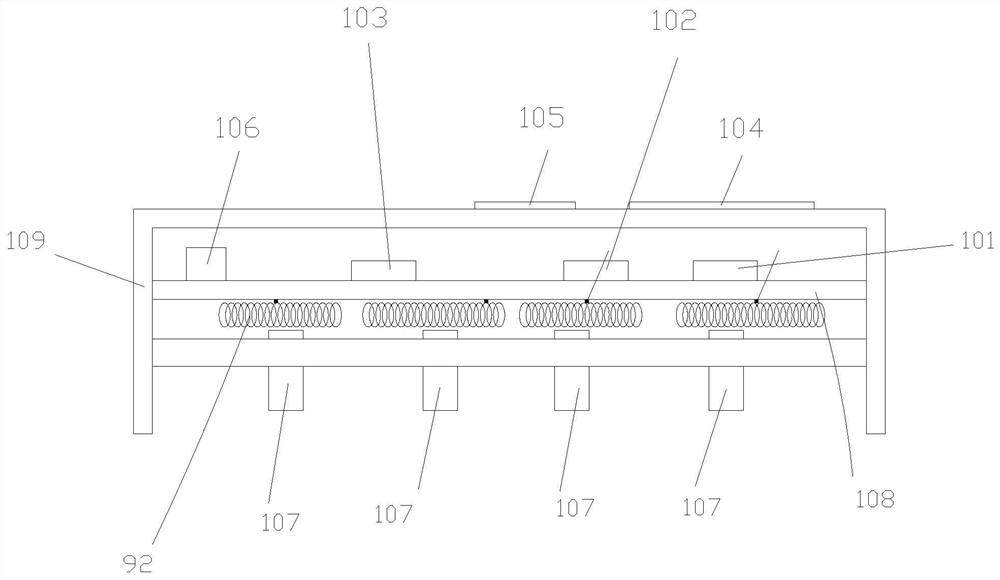

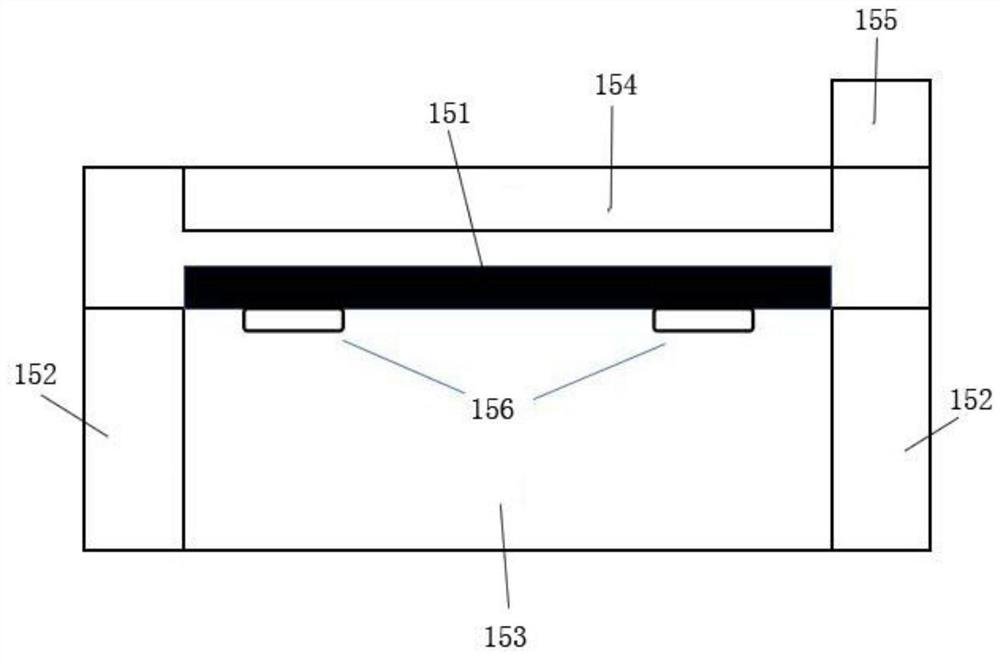

[0023] like Figure 1 to 4An intelligent simulated seismic loading chamber shown, including an analog seismic excitation 1, the acceleration sensor 2, sand cushion 3, the mold box carrier 4, 5 moisture sensors, rainfall simulator 6, 7 measuring system monitoring, manual The operation panel 8, data acquisition controller 9, groundwater analog controller 10, and a computer software system 11, the data transmitter 12 stores, pore water pressure sensor 13, the electromagnetic valve 14 automatically controlled, vertical loads loading system 15, power supply 16 17 and mold box, the mold box the mold box 17 is fixedly mounted on the carrier 4, the seismic modeling energizer tank wall 1 is fixed at X, Y, Z three directions of the mold box 17, wherein the Z-direction excitation fixed at the bottom of the mold box, the electromagnetic excitation using the excitation system excitation, breaking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com