Extrusion-type backing plate for photovoltaic cell and preparation method of backing plate

A photovoltaic cell and extrusion technology, applied in chemical instruments and methods, applications, circuits, etc., can solve the problems of lack of flame retardancy, achieve improved flame retardancy, simple and easy preparation method, and good flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An extruded back sheet for photovoltaic cells, the preparation method of which is as follows:

[0036] (1) Surface treatment of the filler: weigh a certain amount of silane coupling agent KH550 (1% of the glass fiber mass), add a small amount of ethanol aqueous solution; weigh the glass fiber and place it in a high-speed mixer, and heat up while stirring at a high speed To 60°C, add the coupling agent solution drop by drop; after the dropwise addition, continue to mix at high speed for 20 minutes; after the mixing is completed, take out the treated glass fiber, dry it in a blast drying oven at 120°C for 1 hour, and set aside;

[0037] (2) Preparation of nano-flame retardant: add ethanol to the container, heat it to 60°C, then add water and a certain amount of cage polysilsesquioxane, water and cage polysilsesquioxane successively under stirring The molar ratio of siloxane is 3:1; after stirring and dispersing for 1min, add nano-aluminum hydroxide and continue stirring a...

Embodiment 2

[0044] An extruded flame-retardant backboard, the preparation method of which is as follows:

[0045] (1) Surface treatment of filler: weigh a certain amount of silane coupling agent KH550 (1% of the carbon fiber mass), add a small amount of ethanol aqueous solution; weigh the carbon fiber and place it in a high-speed mixer, and heat up to 60°C while stirring at a high speed ℃, add the coupling agent solution drop by drop; after the dropwise addition, continue to mix at high speed for 20 minutes; after the mixing is completed, take out the treated carbon fiber, dry it in a blast drying oven at 120℃ for 1 hour, and set aside;

[0046] (2) Preparation of nano-flame retardant: add ethanol to the container, heat it to 60°C, then add water and a certain amount of cage polysilsesquioxane, water and cage polysilsesquioxane successively under stirring The molar ratio of siloxane is 3:1; after stirring and dispersing for 1min, add nano-magnesium hydroxide and continue stirring at 60°C ...

PUM

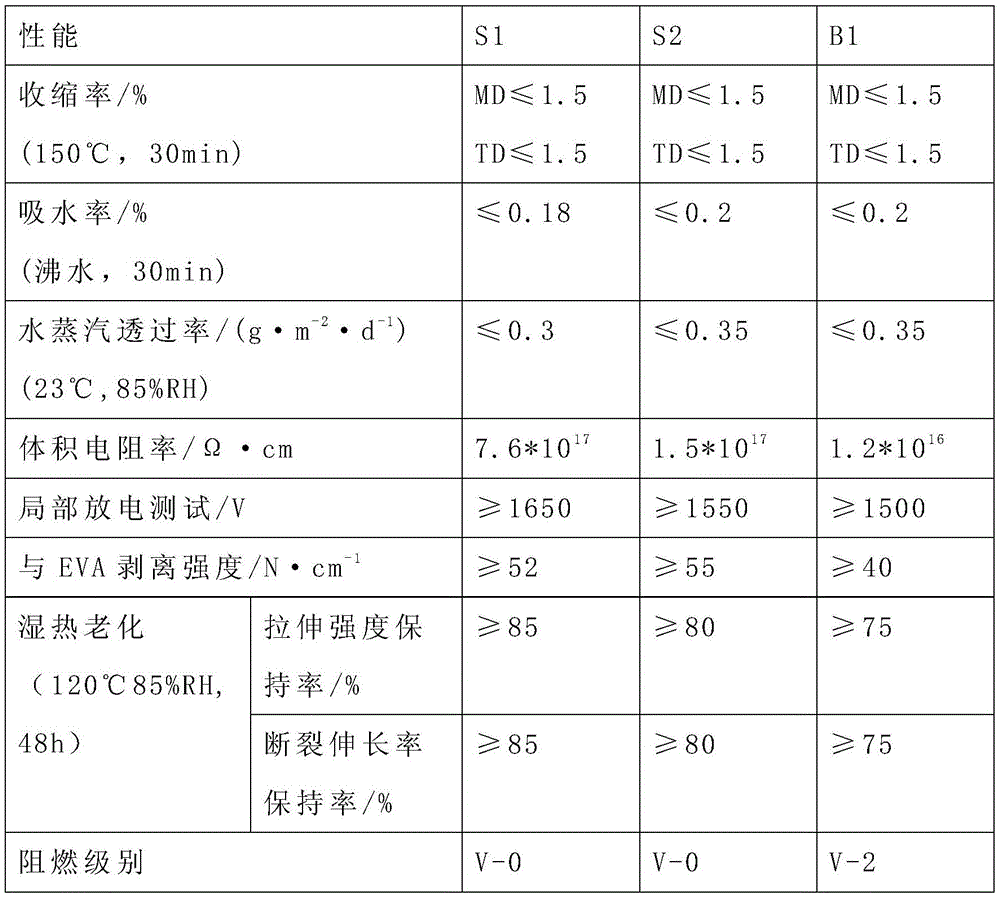

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com