Display panel and display device

A technology for display panels and substrates, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problem of water and oxygen intrusion into the display light-emitting layer of the thin-film encapsulation layer, and achieve the effect of avoiding peeling off and ensuring the encapsulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

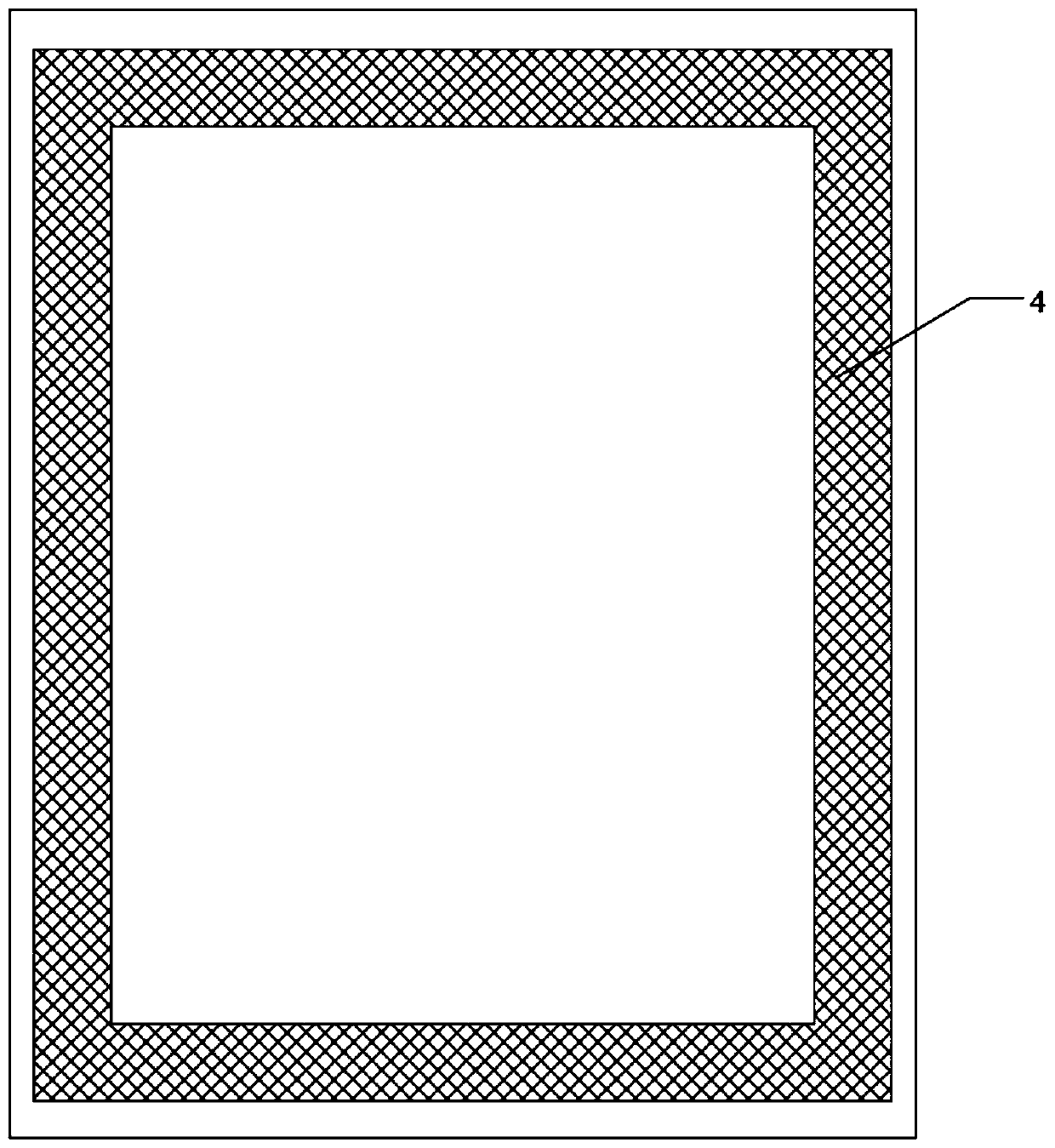

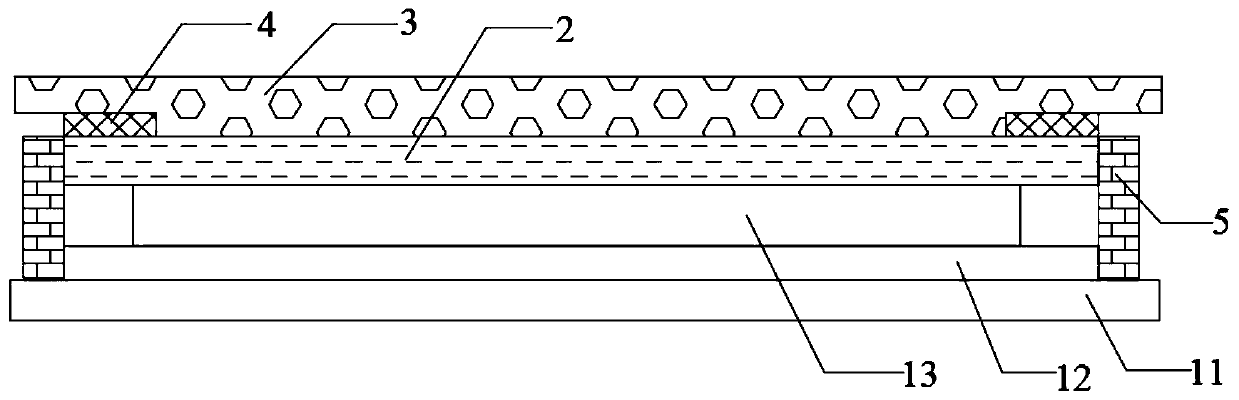

[0022] As mentioned in the background art, there is a technical problem in the prior art that when the protective film is removed, the thin-film encapsulation layer is also peeled off, causing water and oxygen to intrude into the light-emitting layer of the display. The reason why such a problem arises is as follows. After the film encapsulation is completed, before the polarizer is attached, a protective film will be pasted on the outside of the film encapsulation layer to protect it, and the protective film will be removed when it is necessary to attach the polarizer. Due to the characteristics of the thin film encapsulation material and the protective film material itself, the adhesive force between the thin film encapsulation layer and the organic light-emitting layer is smaller than the adhesive force between the protective layer and the thin film encapsulation layer. When the protective film is removed, the thin-film encapsulation layer is also easily peeled off, causing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com