Anti-aging halogen-free flame retardant thermoplastic polyurethane elastomer

A technology of thermoplastic polyurethane and elastomer, which is applied in the field of aging-resistant halogen-free flame-retardant thermoplastic polyurethane elastomer and thermoplastic polyurethane elastomer, and can solve the problem of reducing the mechanical properties of materials such as tensile strength, elongation at break, and deterioration of material aging performance, etc. Problems, to achieve the effect of improving heat aging resistance, heat aging resistance, flame retardant and anti-dripping, and improving high temperature and high humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

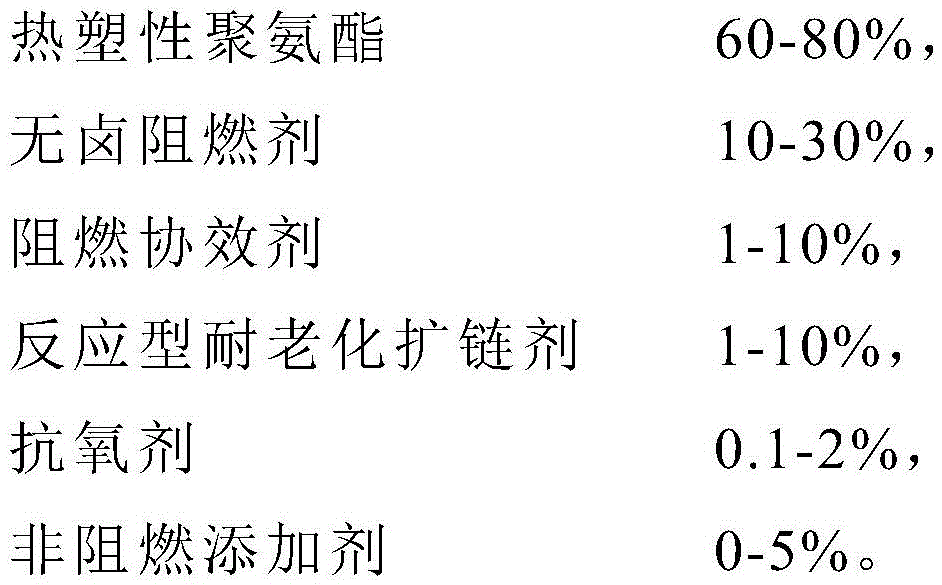

Method used

Image

Examples

Embodiment 1

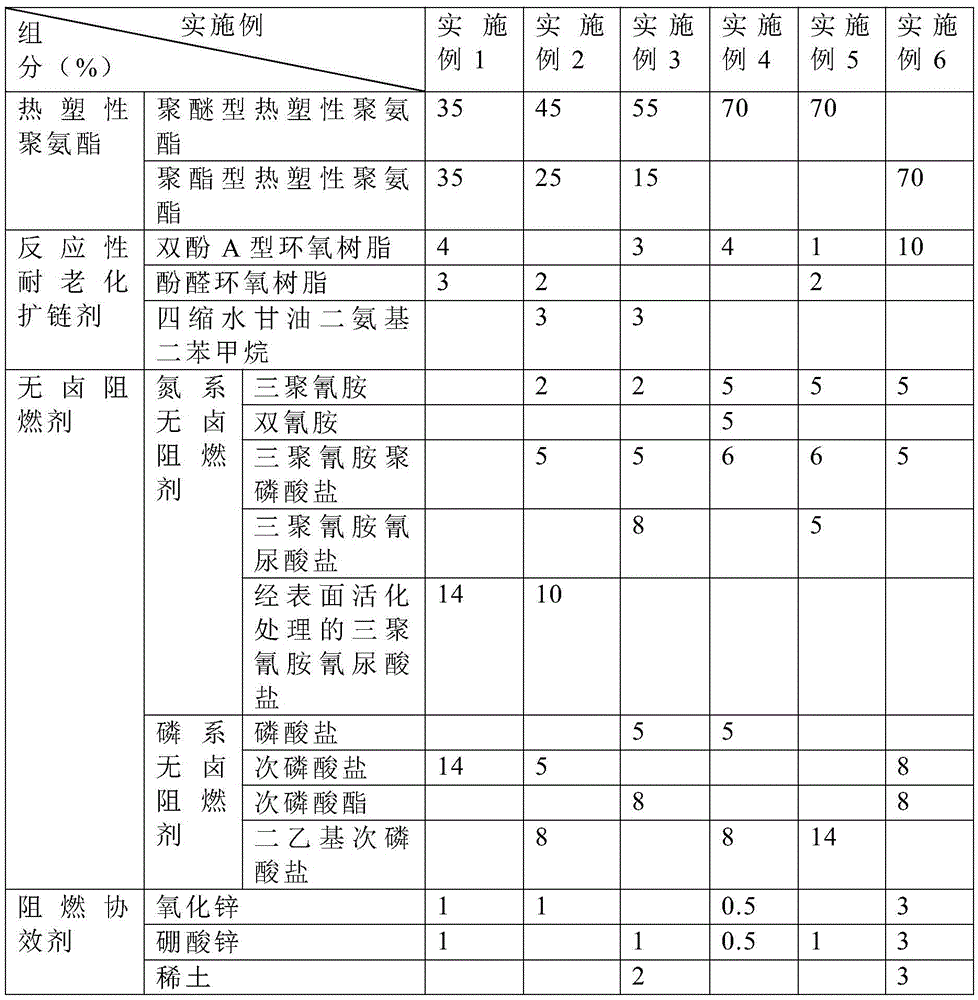

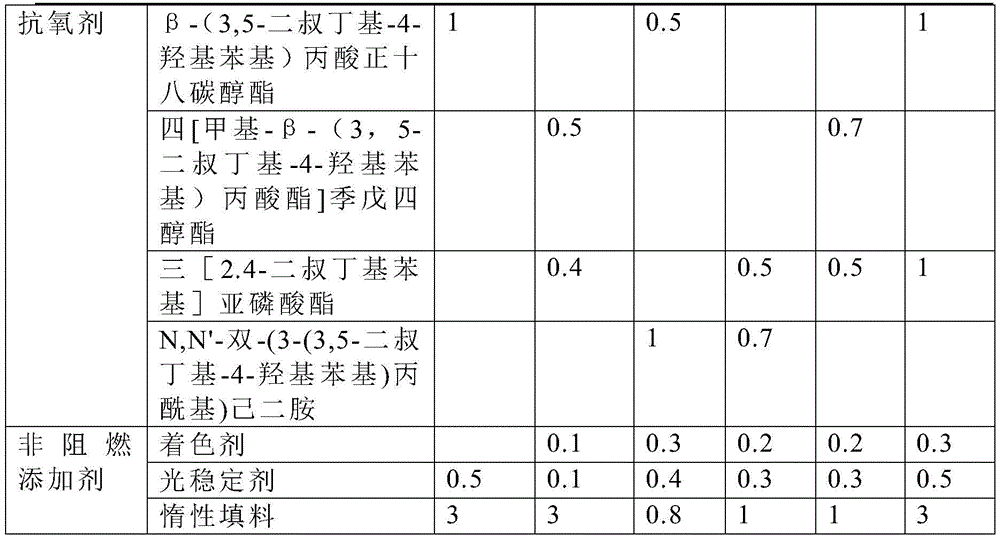

[0035] Weigh the flame retardant, flame retardant synergist, reactive anti-aging chain extender, non-flame retardant additive, antioxidant according to the components and their weight percentages described in Table 1 Example 1, and mix for 5-10min (preferably 5-7min), into a well-mixed mixture;

[0036] Weigh the thermoplastic polyurethane according to the components and weight percentages described in Example 1 of Table 1, and dry at 80-110°C for 3-8h (preferably 90-100°C for 3-5h);

[0037]Mix the mixture with the dried thermoplastic polyurethane for 5-10 minutes until the material is uniform, then extrude, draw, and granulate in a screw extruder at 150-210°C (preferably 160-190°C), and the speed of the screw machine is 180- 600 rpm (preferably 180-400 rpm), to obtain the aging-resistant halogen-free flame-retardant thermoplastic polyurethane elastomer of the present invention.

Embodiment 2-6

[0039] The materials were weighed according to the components and weight percentages described in Examples 2-6 in Table 1, and the aging-resistant halogen-free flame-retardant thermoplastic polyurethane elastomer of the present invention was obtained through the process as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com