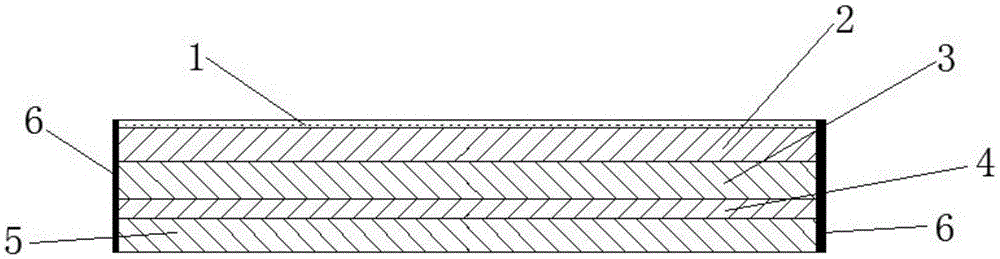

Nanofiber mouth mask capable of effectively blocking PM0.3 and rich in nanometer antibacterial ingredients

A technology of nanofibers and antibacterial ingredients, applied in the field of daily protective products, can solve the problems of high respiratory resistance, low comfort, decreased filtration efficiency, etc., and achieve the effects of reducing allergic reactions, high blocking efficiency, and small respiratory resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Take the gram weight as 10g / m 2 PP spunbond fabric is the first non-woven fabric layer of the mask.

[0021] (2) Prepare 3% nano-silver particle aqueous solution, ultrasonically disperse for 60min, add water-soluble chitosan powder, be mixed with chitosan concentration and be a solution of 5wt%, spray the solution configured on (1) with electrospray method The first nonwoven layer in the spunbond.

[0022] (3) The gram weight is 20g / m 2 The SMS spunbond fabric is the second non-woven fabric layer of the mask, which is used as the inside of the mask.

[0023] (4) Dissolve polyacrylonitrile (PAN) powder in N,N-dimethylformamide (DMF) to configure a spinning solution with a concentration of 11wt%, inject the solution into the metering pump, and the metering pump and the spinning needle pass through The pipeline is connected, and the grammage of the rough filter layer is 22g / m 2 The electret meltblown cloth is placed on the electrospinning metal mesh plate, the spin...

Embodiment 2

[0027] (1) Take the gram weight as 20g / m 2 PP spunbond fabric is the first non-woven fabric layer of the mask.

[0028] (2) Prepare 5% aqueous solution of nano-silver particles, ultrasonically disperse for 60 min, add sodium alginate powder, and prepare a solution with a concentration of sodium alginate of 6 wt%, and apply the prepared solution to the solution in (1) by coating method The first nonwoven layer is on the spunbond.

[0029] (3) The gram weight is 30g / m 2 The SMS spunbond fabric is the second non-woven fabric layer of the mask, which is used as the inside of the mask.

[0030] (4) Dissolve polyurethane (PU) powder in N,N-dimethylacetamide (DMAC) to configure a spinning solution with a concentration of 15wt%, inject the solution into the metering pump, and the metering pump is connected to the spinning needle through a pipeline , Take the electret melt-blown cloth with a grammage of 30g / m2 as the coarse-effect filter layer, place it on the electrospinning receiv...

Embodiment 3

[0034] (1) The gram weight is 30g / m 2 The SMS spunbond fabric is the first non-woven fabric layer of the mask.

[0035] (2) prepare 5wt% nano-silver particle aqueous solution, ultrasonically disperse for 60min, add water-soluble chitosan powder, be mixed with chitosan concentration and be a solution of 10wt%, spray the solution configured on (1) with electrospray method The first nonwoven layer in the spunbond.

[0036] (3) Get the 20g / m2 PP spunbonded cloth as the second non-woven fabric layer of the mask as the inside of the mask.

[0037] (4) Dissolve polystyrene (PS) powder in N,N-dimethylformamide (DMF) to configure a spinning solution with a concentration of 8wt%, inject the solution into the metering pump, and the metering pump and the spinning needle pass through The pipeline is connected, and the grammage of the coarse filter layer is 40g / m 2 The electrostatic cotton is placed on the electrospinning metal mesh plate, the spinning needle is placed above the metal me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com