Chemical analysis determination method of zinc content of molecular sieve

A determination method and molecular sieve technology, applied in the field of analytical chemistry, can solve the problems of system error and high cost of instruments and equipment, and achieve the effects of low cost, high accuracy, and eliminating the influence of zinc content determination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The measurement process is as follows:

[0044] 1. Calibration: the titer T of EDTA standard solution to zinc:

[0045] Pipette 15.00 mL of zinc standard solution, add a little water, add 20 mL of hexamethylenetetramine (30%), a drop of xylenol orange, and titrate with EDTA standard solution to yellow as the end point.

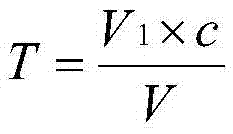

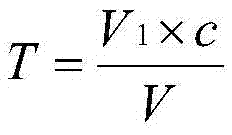

[0046] Calculation: Calculate the titer T of EDTA standard solution to zinc according to the following formula:

[0047] T = V 1 × c V

[0048] Where: V 1 - Pipette the volume mL of zinc standard solution.

[0049] c—concentration of zinc standard solution in g / mL.

[0050] V - Volume mL of EDTA standard solution consumed for titration.

[0051] T = 15.00 × 0.0001 1.91 = 0.00079 ...

Embodiment 2

[0058] Embodiment 2 (sample M, ZnO content is 0.45%):

[0059] Weigh 0.9891 g of the sample, and all the other conditions are the same as in Example 1.

[0060]

[0061] First determination: Z n O ( % ) = 0.44 × 0.00079 × 10 × 81 / 65 0.9891 = 0.4379 % .

[0062] Second determination: Z n O ( % ) = 0.45 × 0.00079 × 10 × 81 / 65 0.9891 = 0.4479 % .

[0063] T...

Embodiment 3

[0064] Embodiment three (sample N, ZnO content is 0.50%):

[0065] Weigh 0.8201 g of the sample, add 12 mL of ammonium fluoride solution at room temperature around 30°C, and the rest of the conditions are the same as in Example 1.

[0066]

[0067] First determination: Z n O ( % ) = 0.42 × 0.00079 × 10 × 81 / 65 0.8201 = 0.5042 % .

[0068] Second determination: Z n O ( % ) = 0.41 × 0.00079 × 10 × 81 / 65 0.820...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com