Method and system for brittle fracturing of brittle semiconductor materials

A semiconductor and brittle technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of reduced bending strength of brittle semiconductor materials, affecting the use of brittle semiconductor materials, and low cutting efficiency, etc., to improve the efficiency of splitting, Elimination of micro-cracks and stress concentration, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

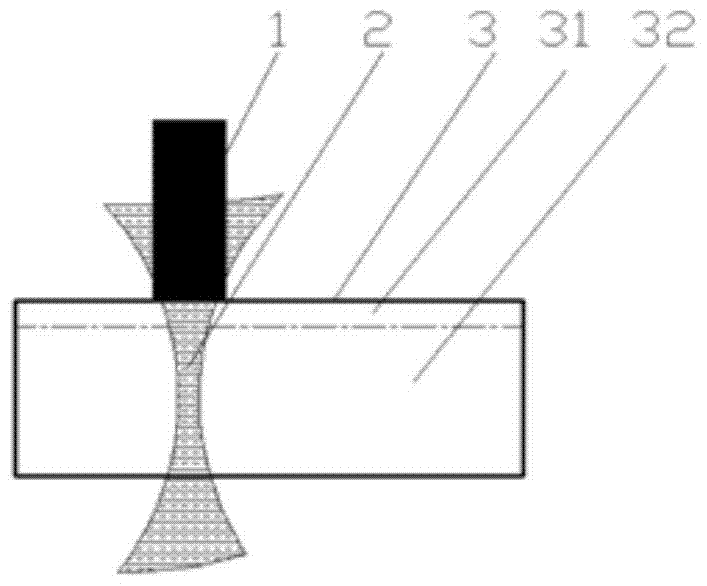

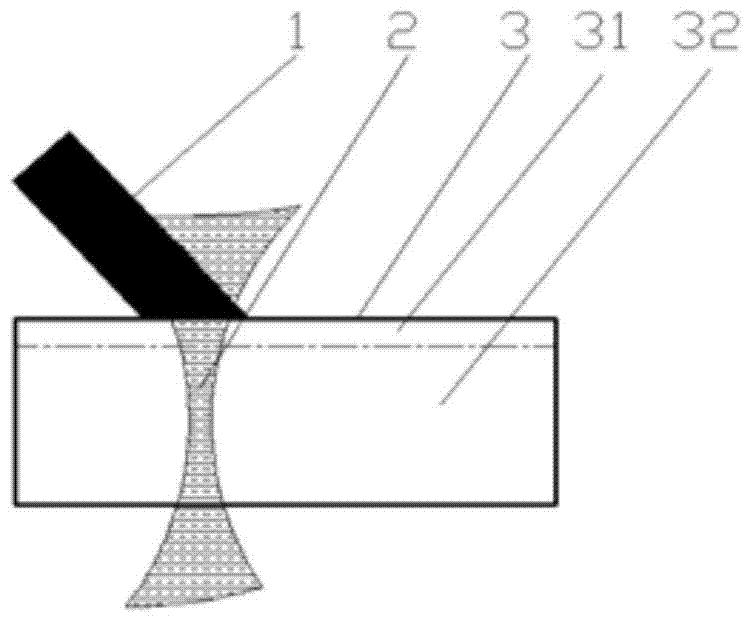

[0042] Embodiment 1. A method for brittle fracturing of brittle semiconductor materials. The following combination Figure 1-a to Figure 2-b The method provided in this embodiment will be described in detail.

[0043] see Figure 1-a and Figure 1-b As shown, the method provided in this embodiment includes: using a heating laser beam to rapidly heat the inside of the brittle semiconductor material to be split, so that the internal expansion of the brittle semiconductor material to be split forms a compressive stress, and at the same time, the brittle semiconductor material to be split The surface of the part is cooled rapidly, so that the surface of the part to be split of the brittle semiconductor material shrinks to form tensile stress, so that the brittle semiconductor material undergoes brittle fracture and a smooth cut is formed. Wherein, the brittle semiconductor material is optically transparent or partially optically transparent to the heating laser beam, so that the...

Embodiment 2

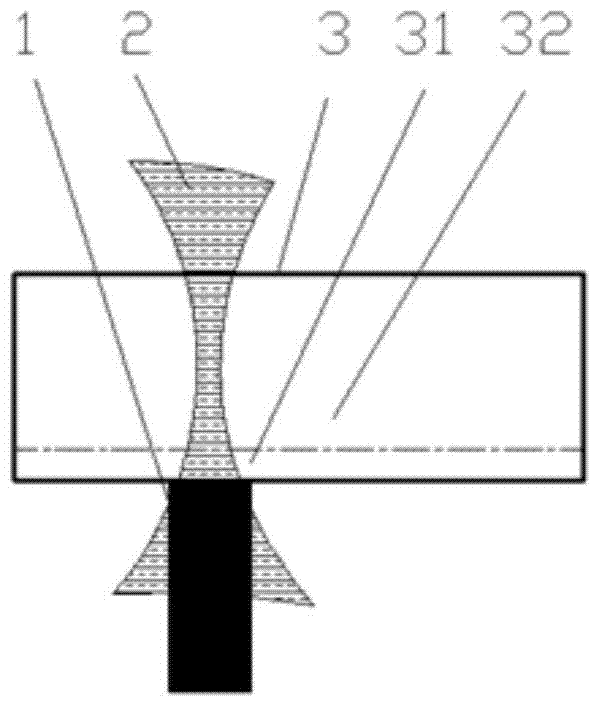

[0055] Embodiment 2. A brittle fracture system of brittle semiconductor materials. The following combination Figure 3-a and Figure 3-b The system provided by this embodiment is described.

[0056] see Figure 3-a As shown, the system provided by this embodiment includes a heating module and a cooling module, wherein the heating module uses a heating laser beam 2 to rapidly heat the inside 32 of the brittle semiconductor material 3 to be split, so that the brittle semiconductor material 3 to be split The internal 3 expands to form compressive stress; at the same time, the cooling module rapidly cools the surface 31 of the brittle semiconductor material 3 to be split, so that the surface 31 of the brittle semiconductor material 3 to be split shrinks to form tensile stress, so that the brittle semiconductor material 3 A brittle fracture occurs to form a smooth cut; wherein, the brittle semiconductor material 3 is optically transparent or partially optically transparent to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com