High-quantity hafnium rod manufacturing method

A high-quality, bar technology, used in temperature control, metal rolling, etc., can solve problems such as poor structure uniformity, and achieve the effects of short processing process, good surface quality, and reduced processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

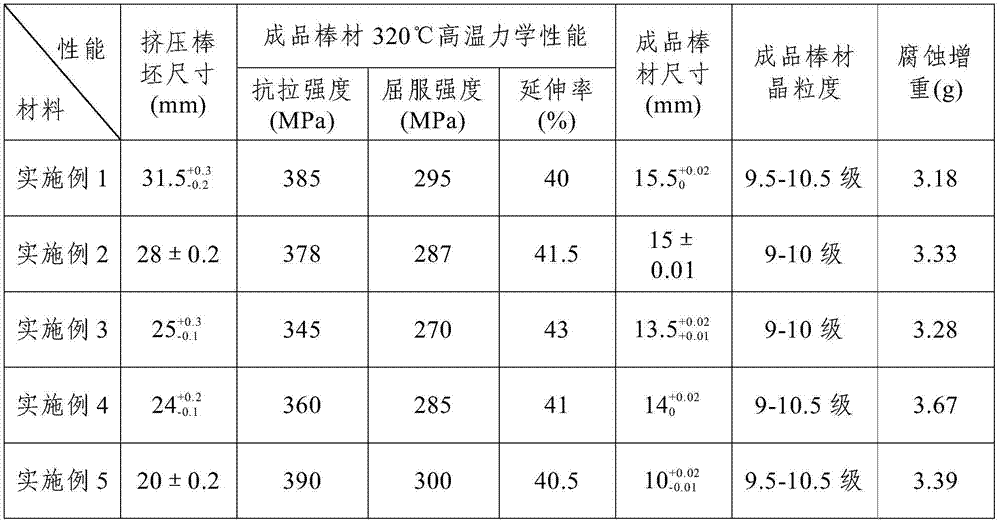

Examples

Embodiment 1

[0026] In this example, a hafnium rod with a diameter of Φ97 mm forged by a conventional forging method is used as a raw material to prepare a hafnium rod with a diameter of Φ15.5 mm. The preparation method includes the following steps:

[0027] Step 1. Coating steel pipes on the hafnium billets, and then covering the steel pipes with copper tubes to obtain double-coated hafnium billets; the steel pipes are A3 steel pipes; the unilateral assembly of the steel pipes and the copper pipes The thickness is 1.0mm;

[0028] Step 2. Heat the double-coated hafnium billet described in step 1 to 850°C and keep it warm for 90 minutes; preheat the extrusion die to 350°C, and extrude the double-sheathed hafnium billet after heat preservation. The cylinder diameter is Φ100mm, the extrusion ratio is 10, and the extrusion speed is 80mm / s, and an extruded billet with a diameter of Φ31.5mm is obtained;

[0029] Step 3, removing the copper pipe and steel pipe covered by the extruded billet desc...

Embodiment 2

[0035] In this embodiment, a hafnium bar blank with a diameter of Φ97 mm forged by a conventional forging method is used as a raw material to prepare a hafnium bar with a diameter of Φ15 mm. The preparation method includes the following steps:

[0036] Step 1. Coating a steel pipe on the hafnium billet, and then coating a copper pipe on the steel pipe to obtain a double-coated hafnium billet; the steel pipe is an A3 steel pipe (other grades of steel pipes can also be used); the steel pipe The total thickness of one side of the copper tube and the copper tube is 1.2mm;

[0037] Step 2. Heat the double-coated hafnium billet described in step 1 to 900°C and keep it warm for 90 minutes; preheat the extrusion tool and die to 350°C, and extrude the double-sheathed hafnium billet after heat preservation. The cylinder diameter is Φ100mm, the extrusion ratio is 12.7, the extrusion speed is 60mm / s, and the extruded billet with the diameter of Φ28mm is obtained;

[0038]Step 3, removing...

Embodiment 3

[0044] In this example, a hafnium rod with a diameter of Φ96 mm forged by a conventional forging method is used as a raw material to prepare a hafnium rod with a diameter of Φ13.5 mm. The preparation method includes the following steps:

[0045] Step 1. Coating a steel pipe on the hafnium billet, and then coating a copper pipe on the steel pipe to obtain a double-coated hafnium billet; the steel pipe is an A3 steel pipe (other grades of steel pipes can also be used); the steel pipe The total thickness of one side of the copper tube and the copper tube is 1.5mm;

[0046] Step 2. Heat the double-coated hafnium billet described in step 1 to 950°C and keep it warm for 60 minutes; preheat the extrusion die to 370°C, and extrude the double-sheathed hafnium billet after heat preservation. The cylinder diameter is Φ100mm, the extrusion ratio is 16, and the extrusion speed is 50mm / s, and an extruded billet with a diameter of Φ25mm is obtained;

[0047] Step 3, removing the copper pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com