Comprehensive treatment process for deep dust removal, desulfurization and denitrification of flue gas from glass kiln

A desulfurization and denitrification and comprehensive treatment technology, applied in the field of flue gas purification, can solve the problems of sodium salt steam easily poisoning SCR catalyst, bag filter material is easy to block, dust removal and desulfurization and denitrification efficiency are not high, so as to achieve easy dust removal and improve ventilation sex, performance-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

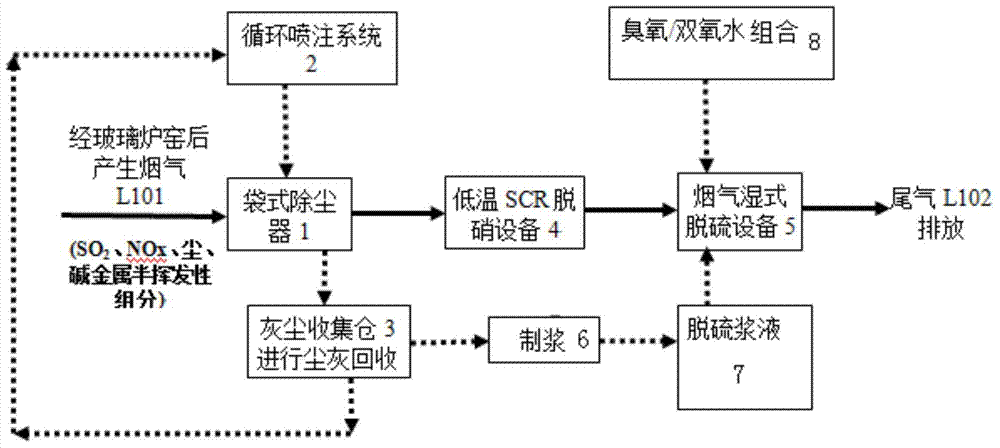

[0027] Such as figure 1 As shown, taking the actual flue gas produced by a certain glass furnace as the treatment object, the flue gas L101 produced after passing through the glass furnace contains SO 2 , NO x , dust, sodium and other semi-volatile vapors, the gas flow rate is 40000m 3 / h. where SO 2 Concentration at 700mg / m 3 left and right, NO x The concentration is about 2000mg / m 3 , the particle concentration is 400mg / m 3 . The raw flue gas L101 is passed into the bag filter 1 through the dust removal flue, and the magnesium oxide powder is injected into the dust removal flue in front of the bag filter 1 by the circulating injection system 2 (the particle size range 200 mesh or so) mixed with dust, the dust comes from the dust collected by the dust collection bin 3 of the bag filter 1, and the amount of magnesium oxide powder used accounts for 10% of the total circulating ash. The concentration of circulating ash injected by system 2 in the flue gas is 500mg / m 3 ...

Embodiment 2

[0033] The actual flue gas produced by a certain glass kiln is treated as the treatment object, among which SO 2 Concentration at 1000mg / m 3 Around, NOx concentration is about 2000mg / m 3 , the particle concentration is 8000mg / m 3 . Use the dry circulation injection system to inject magnesium oxide powder into the bag filter, in which the amount of magnesium oxide accounts for 2% of the total circulating ash. After a period of stability, the dust is collected for pulping and enters the wet Desulfurization tower, blowing a certain concentration of ozone (about 2000mg / m3) into the desulfurization tower 3 ), after the reaction is stable, sample and analyze the flue gas at the outlet of the bag filter and analyze each working condition. The results showed that the addition of magnesium oxide improved the easy removal performance of the filter cake of the bag filter, the SCR catalyst operated normally and was protected from poisoning, SO 2 The removal rate of NOx has reached mo...

Embodiment 3

[0035] The actual flue gas produced by a certain glass kiln is treated as the treatment object, among which SO 2 Concentration at 1000mg / m 3 effect, the NOx concentration is about 2000mg / m 3 , the particle concentration is 8000mg / m 3 . Use the dry circulation injection system to inject magnesium oxide powder into the bag filter to increase the proportion of magnesium oxide powder used. Among them, the amount of magnesium oxide accounts for 20% of the total circulating ash. After a period of stability, collect the dust for dust removal Pulp and enter the wet desulfurization tower, using the combined process of ozone-hydrogen peroxide for desulfurization and denitrification, in which the concentration of ozone is about 2000mg / m 3 , the proportion of hydrogen peroxide accounts for about 1% of the total desulfurization liquid. After the reaction is stable, sample and analyze the flue gas at the outlet of the bag filter and analyze each working condition. The results show that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com