Preparation method for graphene/lead compound composite material and lead-acid battery

A technology of lead compounds and composite materials, applied in the direction of lead-acid batteries, battery electrodes, circuits, etc., can solve the problem that the effective contact interface between lead active material and carbon material is small, the advantages of high conductivity and large capacitance of carbon cannot be fully utilized, and the uniform mixing is very difficult. Difficult to realize and other problems, to achieve the effect of suppressing large particles of lead sulfate, increasing the effective contact area, good capacitance and battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

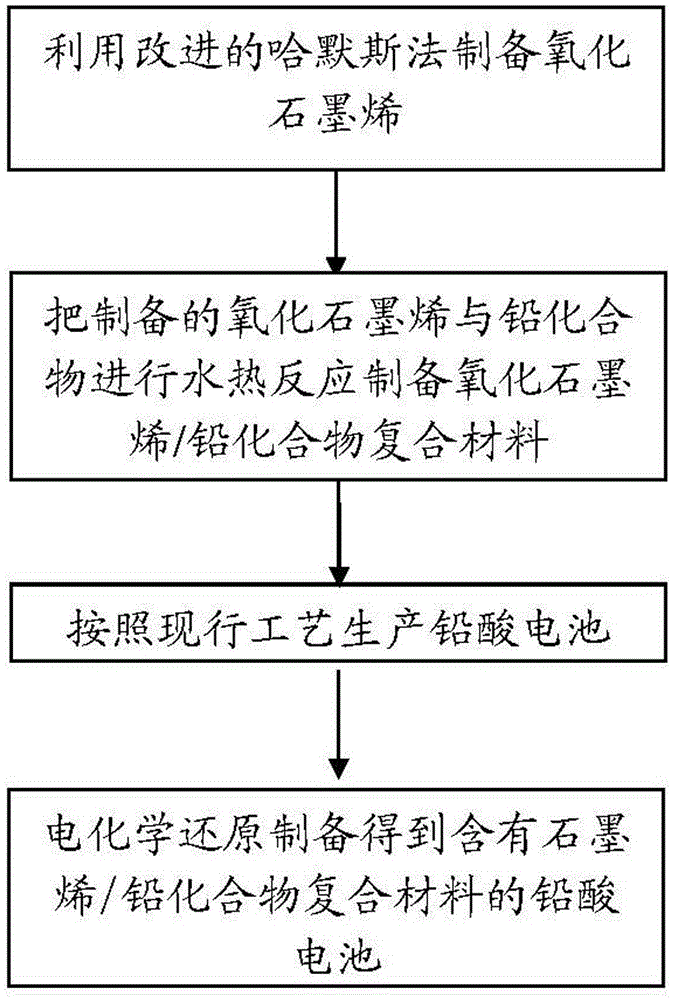

[0029] Specifically, the invention provides a kind of preparation method of graphene / lead compound composite material, it comprises the steps:

[0030] S1. Perform hydrothermal reaction mixing or ball milling of the lead compound and graphene oxide to obtain a graphene oxide / lead compound composite material;

[0031] S2, using the graphene oxide / lead compound composite material as an electrode material additive to assemble a lead-acid battery;

[0032] S3. Perform electrochemical reduction on the lead-acid battery prepared and assembled in step S2 to obtain a lead-acid battery containing graphene / lead compound composite material.

[0033] Among them, graphene is a new type of two-dimensional structure conductive material, and the application of graphene has great significance and great development potential in this field.

[0034] Since Novoselov and Geim exfoliated single-layer graphene from the surface of high-temperature orderly cracked graphite by a simple tape stripping ...

Embodiment 1

[0060] The technological process of this embodiment is as figure 1 As shown, it specifically includes the following steps.

[0061] (1) Hammers (hummers) method to prepare graphene oxide

[0062] Concentrated H 2 SO 4 (69 ml) was added graphite flakes (3.0 g, 1 wt. equivalent) and NaNO 3 (1.5 g, 0.5 wt equiv), the resulting mixture was cooled to 0°C. Slowly add KMnO in batches 4 (9.0 g, 3 wt equiv), the reaction temperature was kept below 20°C. The reaction mixture was warmed to 35°C and stirred for 30 minutes, at which point water (138 mL) was added slowly, with a large exotherm to 98°C. External heating was introduced to maintain the reaction temperature at 98°C for 15 minutes, then the reaction mixture was cooled with a water bath for 10 minutes. Then add more water (420 ml) and 30% H 2 o 2 (3 mL), exotherm again. After air cooling, 1.2 g of the obtained black solid mixture was purified, which was graphene oxide. Different weights of graphene oxide can be prepare...

Embodiment 2

[0073] The technological process of this embodiment is as figure 2 As shown, it specifically includes the following steps.

[0074] (1) Improved Hammers (hummers) method for preparing graphene oxide

[0075]With 325 mesh graphite as the initial raw material, 7.2mL of 98% concentrated sulfuric acid, 1.5g of potassium thiosulfate and 1.5g of phosphorus pentoxide were added to 0.9g of graphite powder. Then the mixture was stirred and reacted at 80° C. for 4.5 h, and then the reactant was diluted with about 500 mL of distilled water, filtered, and the filter cake was dried overnight in a 70° C. blast oven. Put the above-mentioned treated graphite powder into a 250mL beaker, slowly add 23mL of concentrated sulfuric acid and 0.5g of sodium nitrate under an ice-water bath, stir for five minutes, then slowly add 3g of potassium permanganate to it, and stir in an ice-water bath for 30 Minutes, and then slowly warmed to 35 ° C, maintaining the temperature and stirring the reaction fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com