Method and device for preparing phosphorus-rich biofertilizer

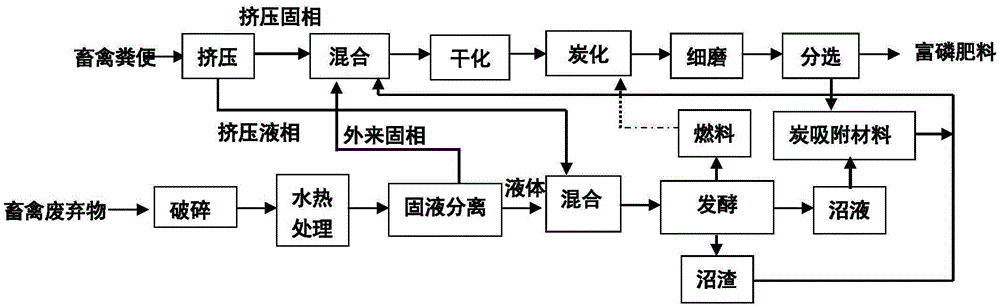

A bio-fertilizer and phosphorus-enriched technology, applied in the direction of waste fuel, etc., can solve the problems of insufficient utilization of livestock and poultry manure resources, large energy consumption, and large floor area, and achieve significant energy-saving benefits, low operating costs, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

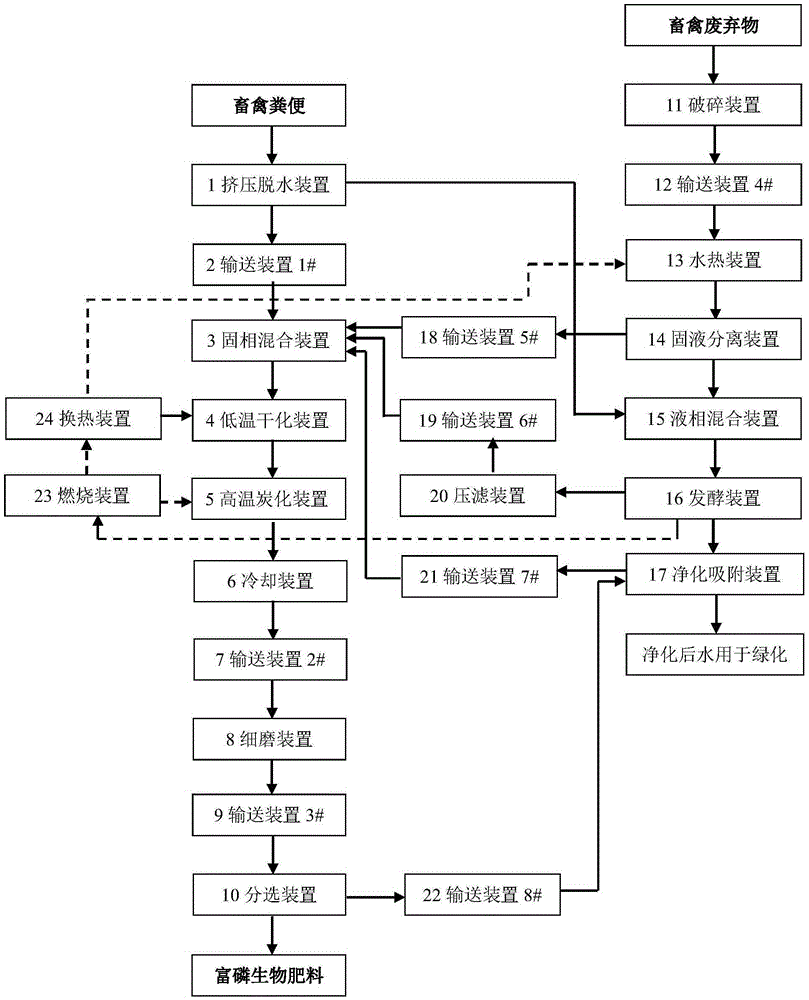

[0069] Extrude livestock and poultry manure to obtain an extruded solid phase with a moisture content of less than 30%, mix it with the foreign solid phase at a mass ratio of 2 / 3 for 30 minutes, and perform drying treatment after mixing. The drying temperature is 80°C, and the product Carry out carbonization, the carbonization temperature is 500°C, and the material residence time is 30 minutes to obtain pyrolytic charcoal. The pyrolytic charcoal is finely ground and sorted to obtain materials with a particle size of 30%) and high phosphorus content (>30%), it can be used as a biological fertilizer, which is environmentally friendly and has excellent performance; the latter is used as a carbon adsorption material, and its specific surface area is >300m 2 / g, the adsorption performance is better.

[0070] Specifically, the foreign solid phase includes the solid phase obtained by solid-liquid separation after crushing and hydrothermal treatment of livestock and poultry waste. Spec...

Embodiment 2

[0075] Extrude livestock and poultry manure to obtain an extruded solid phase with a moisture content of less than 30%, mix it with the foreign solid phase at a mass ratio of 4:1 for 5 minutes, and then carry out drying treatment at a drying temperature of 150°C. The product Carry out carbonization, the carbonization temperature is 1100°C, and the material residence time is 3 minutes to obtain pyrolytic charcoal. The pyrolytic charcoal is finely ground and sorted to obtain materials with a particle size of <100 μm and materials with a particle size of ≥100 μm. The former is used as a phosphorus-rich fertilizer , the latter as carbon adsorption material.

[0076] The foreign solid phase includes the solid phase obtained by solid-liquid separation after crushing and hydrothermal treatment of livestock and poultry waste. Specifically, the temperature of hydrothermal treatment is 100°C, the pressure is 2bar, and the time is 60min; the product of hydrothermal treatment is subjected ...

Embodiment 3

[0081] The livestock and poultry manure is subjected to extrusion treatment in the extrusion dehydration device (1), the obtained extrusion liquid phase is sent to the liquid phase mixing device (15), and the obtained extrusion solid phase is sent to the To the solid phase mixing device (3), after the extruded solid phase and the foreign solid phase are fully mixed in the solid phase mixing device (3), they are sent to the low temperature drying device (4) for drying, and then to the high temperature carbonization device ( 5) for carbonization, then sent to the cooling device (6) for cooling, after cooling, sent to the fine grinding device (8) for fine grinding through the conveying device (7), and then sent to the sorting device through the conveying device (9) The device (10) sorts to obtain materials with a particle size of <100 μm and materials with a particle size of ≥100 μm, the former is used as a phosphorus-rich fertilizer, and the latter is used as a carbon adsorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com