Floatation separation method for copper pyrites and iron pyrites

A separation method, pyrite technology, applied in flotation, solid separation, etc., to achieve the effects of low dosage, separation, and low cost of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Mineral raw materials

[0029] Take raw ore from a copper mine in Hebei Province, the copper content is 0.619%, and the sulfur content is 3.262%.

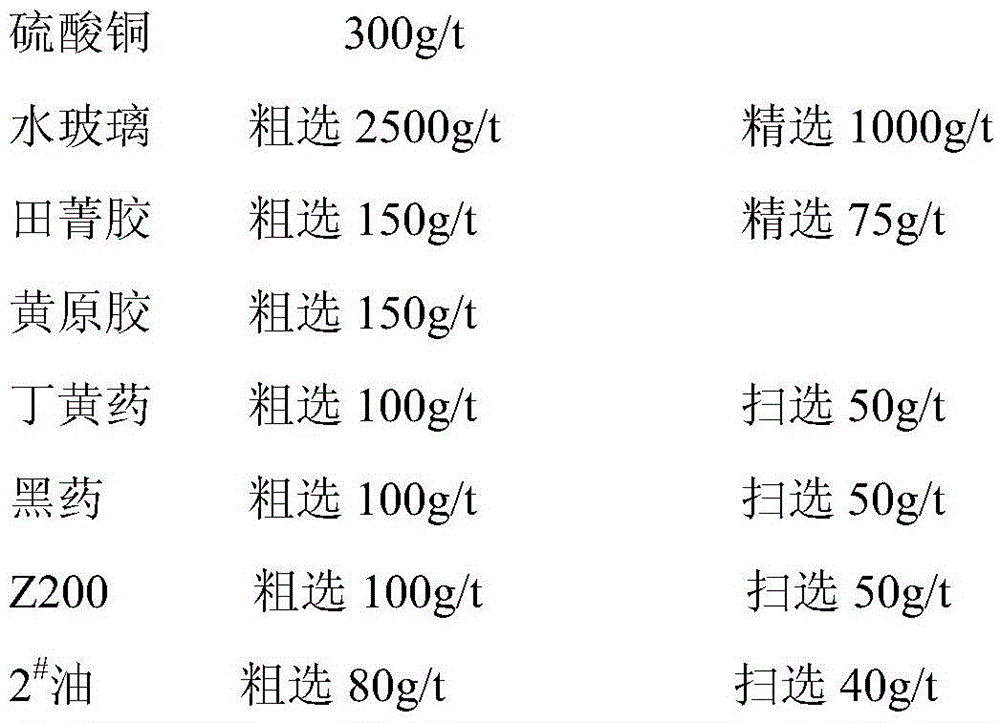

[0030] 2. The total dosage of flotation reagents is:

[0031]

[0032] The operation steps and technical conditions are as follows:

[0033] During the flotation process, the ore is added to the grinding machine for grinding until the mineral monomer dissociates. Under the natural pH condition, copper sulfate is added in sequence as an activator for chalcopyrite, and water glass as an inhibitor for other gangue minerals such as quartz. agent, a mixture of sapphire gum and velvet gum as an inhibitor of pyrite, xanthate as a collector and 2 # Oil is used as a foaming agent for roughing operation to obtain copper rough concentrate and copper rough tailings. The roughing tailings are added with butyl xanthate and 2 # The oil is subjected to copper sweeping, and the sweeping times are 1, and the order of sweeping the con...

Embodiment 2

[0042] 1. Mineral raw materials

[0043] Take raw ore from a copper mine in Xinjiang Province, the copper content is 0.592%, and the sulfur content is 4.010%.

[0044] 2. The total dosage of flotation reagents is:

[0045]

[0046] The operation steps and technical conditions are as follows:

[0047] During the flotation process, the ore is added to the grinding machine for grinding until the mineral monomer dissociates. Under the natural pH condition, copper sulfate is added in sequence as an activator for chalcopyrite, and water glass as an inhibitor for other gangue minerals such as quartz. agent, sapphire gum and xanthan gum mixture as pyrite inhibitor, butyl xanthate, black medicine and Z200 mixture as collector and 2 # Oil is used as a foaming agent for roughing operation to obtain copper rough concentrate and copper rough tailings. The roughing tailings are added with butyl xanthate, black medicine, Z200 and 2 # The oil is subjected to copper sweeping, and the swe...

Embodiment 3

[0057] 1. Mineral raw materials

[0058] Take raw ore from a copper mine in Jiangxi Province, the copper content is 0.840%, and the sulfur content is 10.135%.

[0059] 2. The total dosage of flotation reagents is:

[0060]

[0061] The operation steps and technical conditions are as follows:

[0062] During the flotation process, the ore is added to the grinding machine for grinding until the mineral monomer dissociates. Under the natural pH condition, copper sulfate is added in sequence as an activator for chalcopyrite, and water glass as an inhibitor for other gangue minerals such as quartz. agent, sodium hexametaphosphate as pulp dispersant, sapura gum as pyrite inhibitor, butyl xanthate as collector and 2 # Oil is used as a foaming agent for roughing operation to obtain copper rough concentrate and copper rough tailings. The roughing tailings are added with butyl xanthate and 2 # The oil is subjected to copper sweeping, and the sweeping times are 2 times, and the ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com