A composite nano-antibacterial material for the treatment of vancomycin-resistant pathogens

An antibacterial material, vancomycin technology, applied in antibacterial drugs, preparations for in vivo experiments, wave energy or particle radiation treatment materials, etc., can solve the problem of low excitation efficiency of near-infrared light sources and poor fluorescence performance of porphyrin molecules. In order to improve water solubility and biocompatibility, it is not easy to interfere with sample autofluorescence, and the spectral bandwidth is narrow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

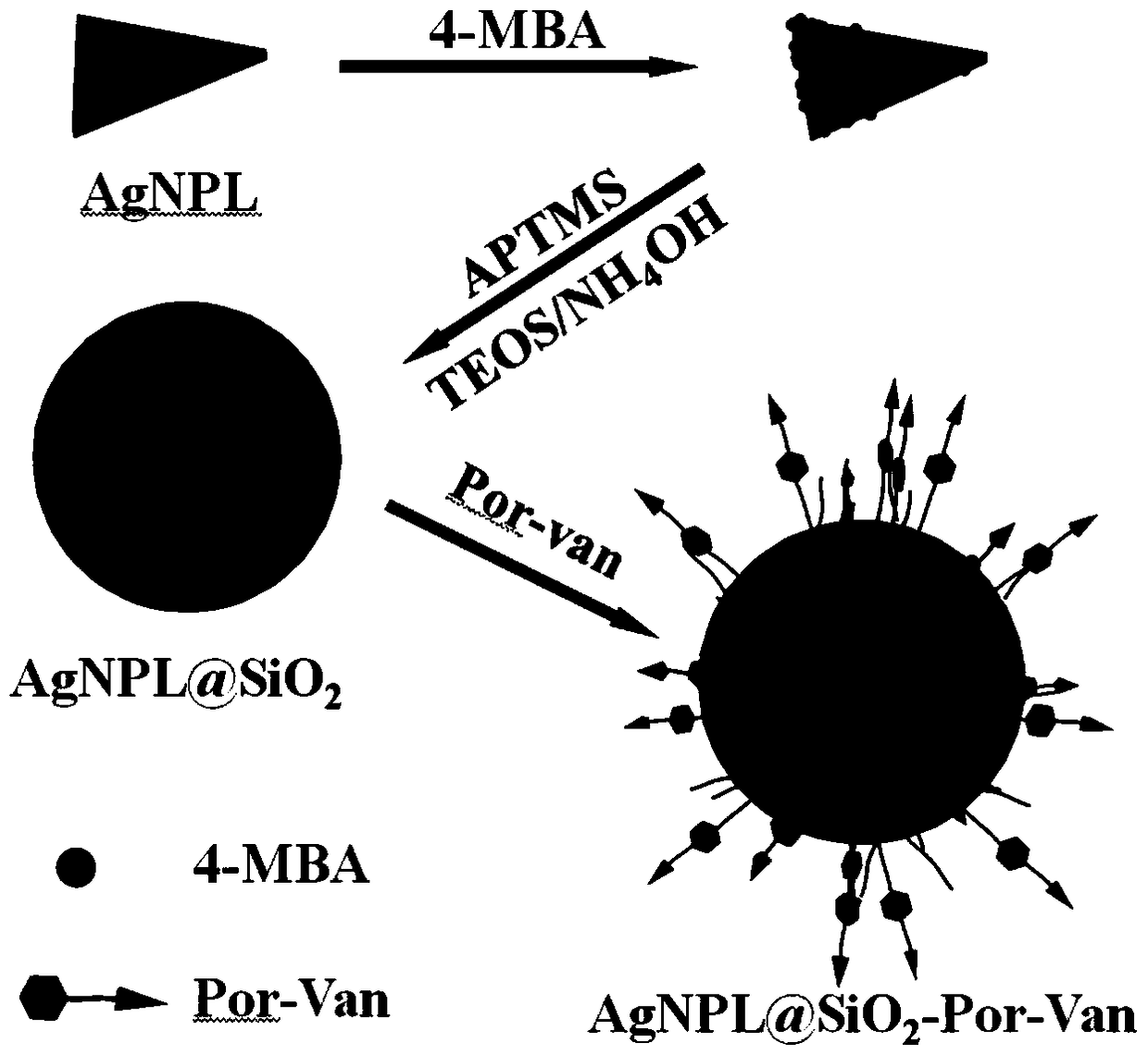

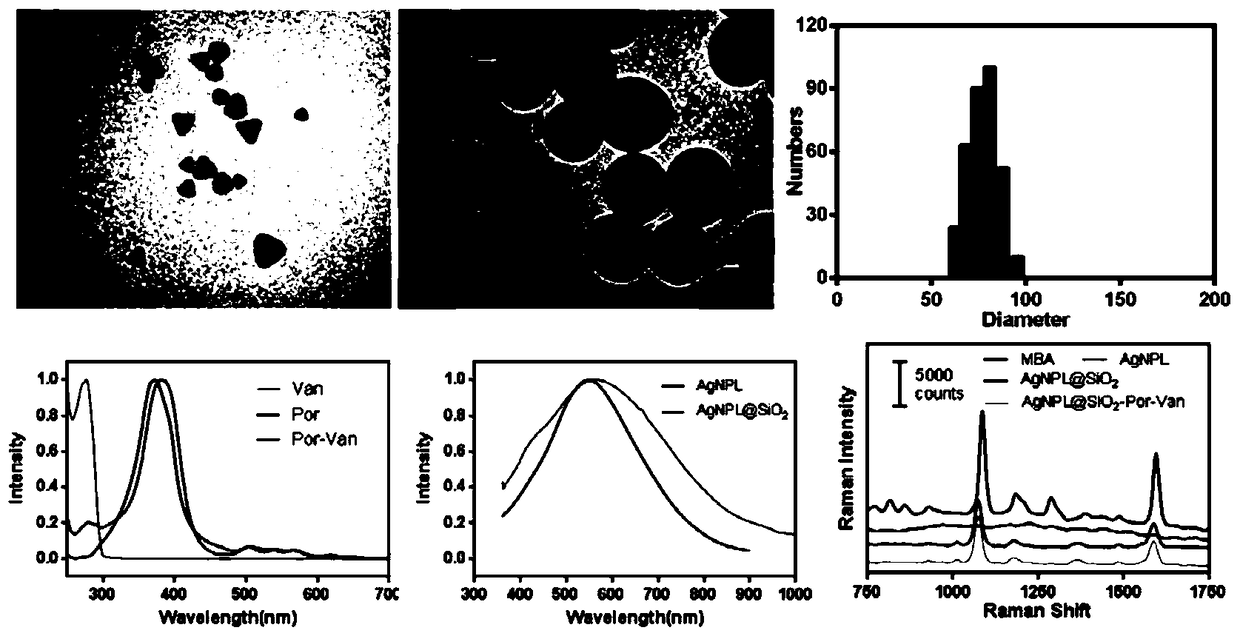

[0032] A kind of preparation process of composite nano antibacterial material is as follows:

[0033] (1) Synthesis of vancomycin-porphyrin monomer:

[0034] Dissolve 52.8 mg of vancomycin and 20.8 mg of porphyrin in 2 mL of dry dimethyl sulfoxide, stir in an ice bath for 10 min, then add 38.0 mg of O-benzotriazepam dissolved in 1 mL of N,N-dimethylformamide Azole-tetramethyluronium hexafluorophosphate and 0.06 mL of N,N-diisopropylethylamine. The ice bath was removed, and the reaction was stirred overnight. At the end of the reaction, 20 mL of acetone was added dropwise to obtain a dark purple solid precipitate, which was then washed once with 5 mL of acetone and separated by high performance liquid chromatography to obtain the vancomycin-porphyrin monomer.

[0035] (2) Preparation of triangular silver nanosheets (AgNPL):

[0036]Add 200μL of 50mM silver nitrate solution and 2mL of 75mM sodium citrate solution into 96mL of ultrapure water in turn, and after rapid stirring,...

Embodiment 2

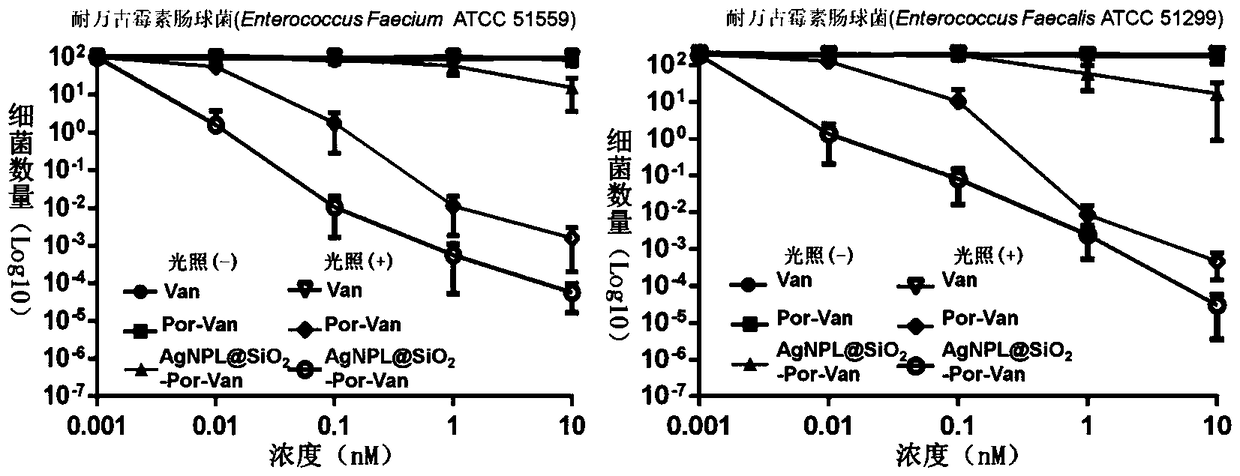

[0042] Example 2: The composite nano antibacterial material is used for in vitro photodynamic antibacterial treatment of vancomycin-resistant Enterococcus Faecalis (ATCC 51299).

[0043] Pick the monoclonal strain from the LB plate into 5mL LB medium and culture overnight at 37°C. Bacteria were collected by centrifugation at 4000rpm, washed 3 times with sterile PBS buffer, and the OD was adjusted by resuspending the bacterial pellet with PBS buffer 600 is 0.5. Then take 500 μL of bacterial liquid and mix it with different concentrations of composite nano-antibacterial materials and its components, and place it in a 37°C incubator for 15 minutes before performing light or non-light treatment. All illumination experiments were carried out with xenon lamp (400nm-800nm) and the illumination time was 0-2min. Then take 100 μL of the treated bacterial solution and dilute it with sterile PBS buffer to a certain number of times, add it to an LB culture plate, and culture it overnight...

Embodiment 3

[0045] Example 3: The composite nano antibacterial material is used for in vitro photodynamic antibacterial treatment of vancomycin-resistant Enterococcus faecalis (ATCC 51299).

[0046] Pick the monoclonal strain from the LB plate into 5mL LB medium and culture overnight at 37°C. Bacteria were collected by centrifugation at 4000rpm, washed 3 times with sterile PBS buffer, and the OD was adjusted by resuspending the bacterial pellet with PBS buffer 600 is 0.5. Then take 500 μL of bacterial liquid and mix it with different concentrations of composite nano-antibacterial materials and its components, and place it in a 37°C incubator for 15 minutes before performing light or non-light treatment. All illumination experiments were carried out with xenon lamp (400nm-800nm) and the illumination time was 0-2min. Then the treated bacterial solution was diluted 10 with sterile PBS buffer 6 Multiple times, pipette 100 μL of the diluted bacterial solution and add it to the LB culture pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com