High-efficiency and energy-saving amorphous alloy transformer employing dry-type bushings led out for completely eradicating leakage

A dry-type bushing and amorphous alloy technology, applied in the field of transformers, can solve problems such as large loss, complex structure, and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

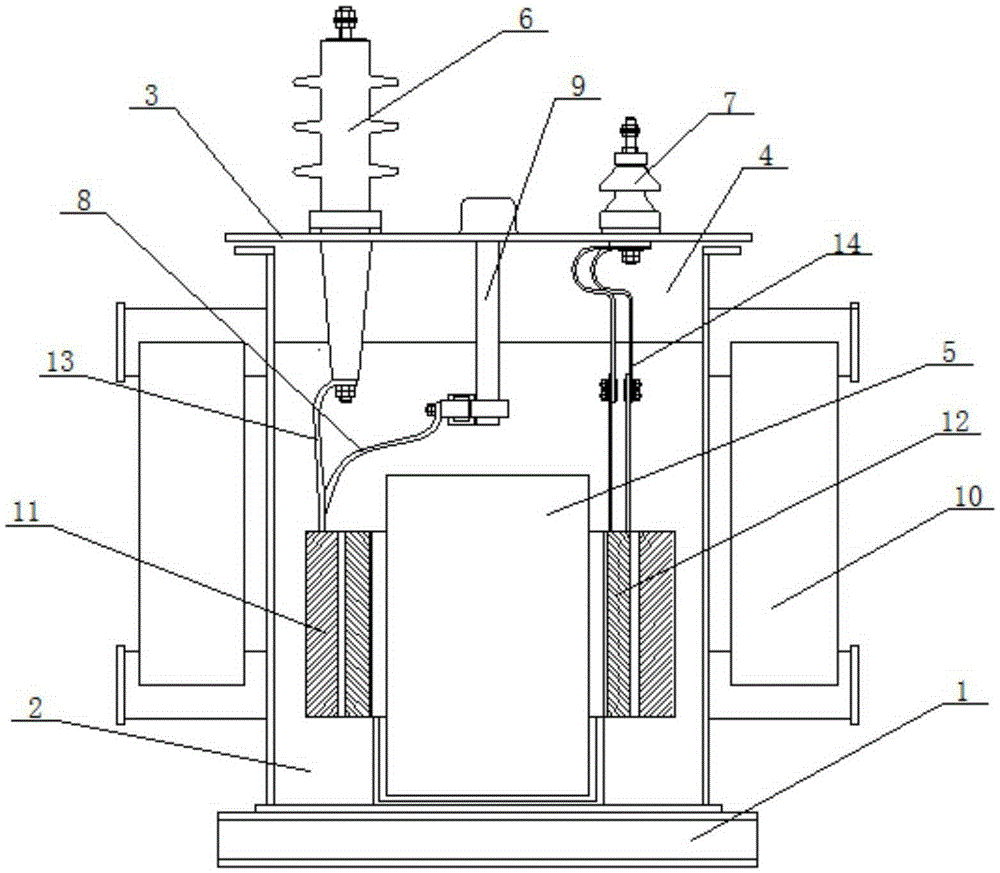

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0023] The invention provides a high-efficiency energy-saving amorphous alloy transformer with a dry-type bushing leading out to prevent leakage. Oil expansion, buffering the heat transfer from transformer oil to the upper cover of the oil tank, reducing the temperature rise of the upper cover of the transformer oil tank, preventing oil spillage on the upper cover of the transformer, and adopting dry bushings without oil filling, blocking the external environment from passing through the bushings The internal channel that affects the insulation performance of transformer oil adopts amorphous alloy iron core, fully utilizes the characteristics of amorphous alloy materials, greatly reduces no-load loss, and achieves the purpose of reducing production costs, reducing no-load loss,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com