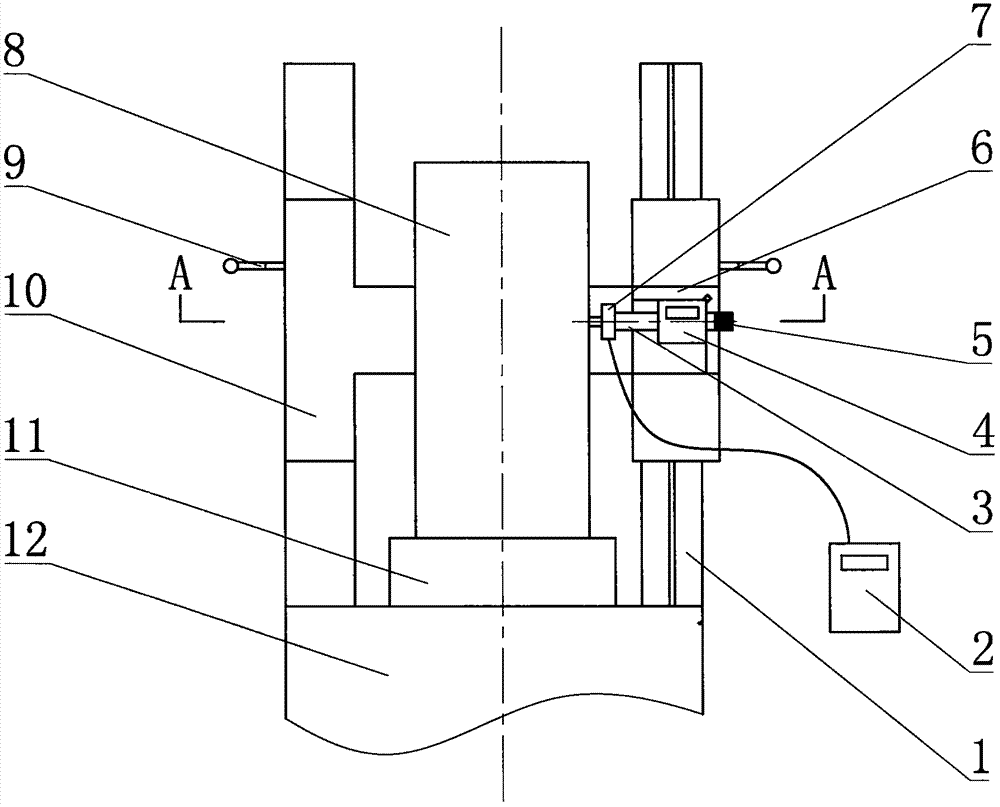

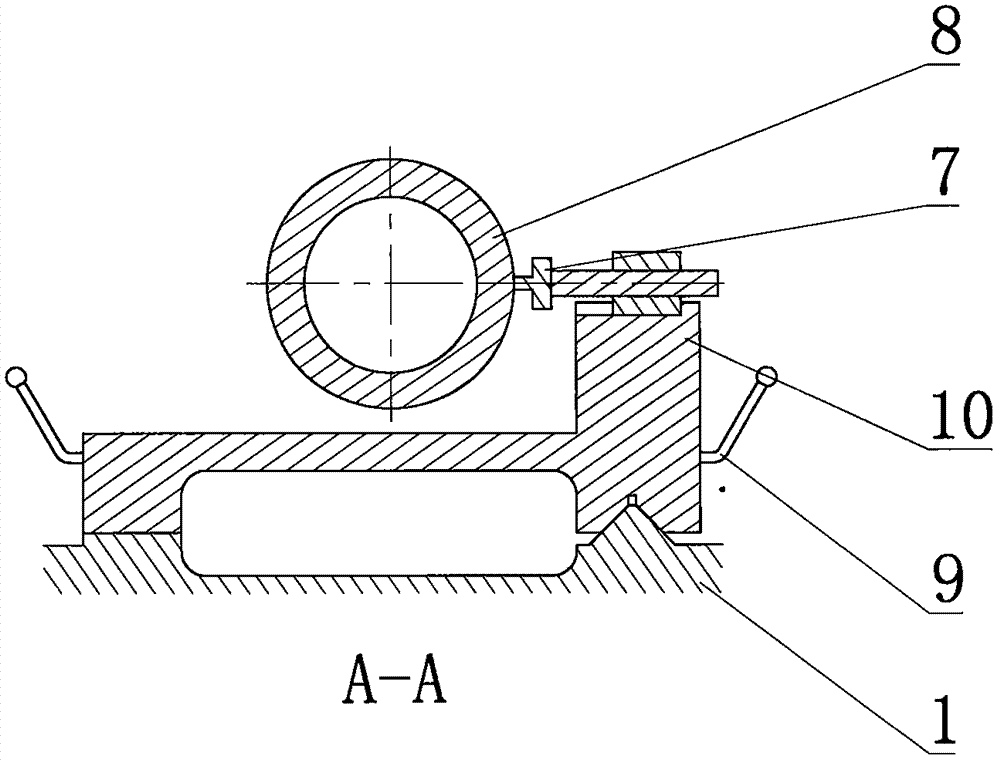

Ultrasonic deep hole straightness detection method and device

A detection method and straightness technology, applied to measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of principle error, misjudgment of the axis of deep hole as a straight line, and the influence of detection results, etc., so as to eliminate the principle error, improve detection efficiency, fix convenient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0041] In the ultrasonic deep hole straightness detection method, in step e of the method, three measurements are performed to obtain the position coordinates of three points on the deep hole wall section, and the other steps are as described above.

Embodiment approach 2

[0043] Ultrasonic deep hole straightness detection method, in step e of the method, the position coordinates of 4 or 5 or 6 or 7 points on the deep hole wall section are obtained by measurement, and the content of other steps is as described above.

Embodiment approach 3

[0045] The device used in the ultrasonic deep hole straightness detection method, the cavity of the detection rack is rectangular. The rest of the parts are as mentioned above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com