Design method and scraping modification process of a scraping tool for cylindrical gear finishing

A cylindrical gear and design method technology, applied in metal processing equipment, manufacturing tools, gear tooth manufacturing devices, etc., can solve the problem of tooth surface distortion, tooth profile modification error, tooth accuracy and other problems caused by tooth direction modification. The problem of accuracy retention is not obtained, and the effect of eliminating the distortion of the tooth surface, improving the cutting performance of the cutter teeth and being beneficial to the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

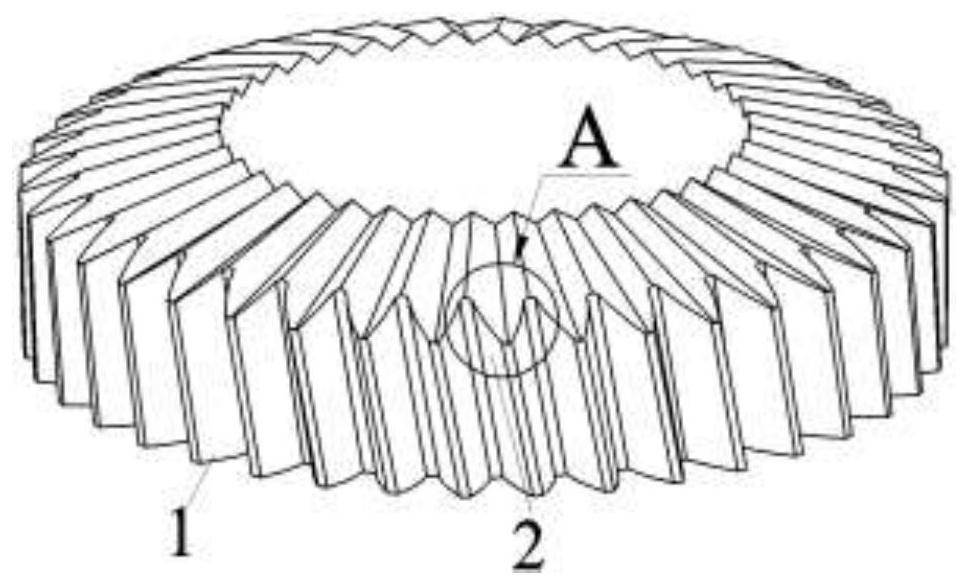

[0064] According to the above method, the finishing scraping tool 1 of the internal gear workpiece is designed, and the related calculation of scraping and modification processing is carried out; the basic parameters of the internal gear workpiece are shown in Table 1.

[0065] Table 1

[0066]

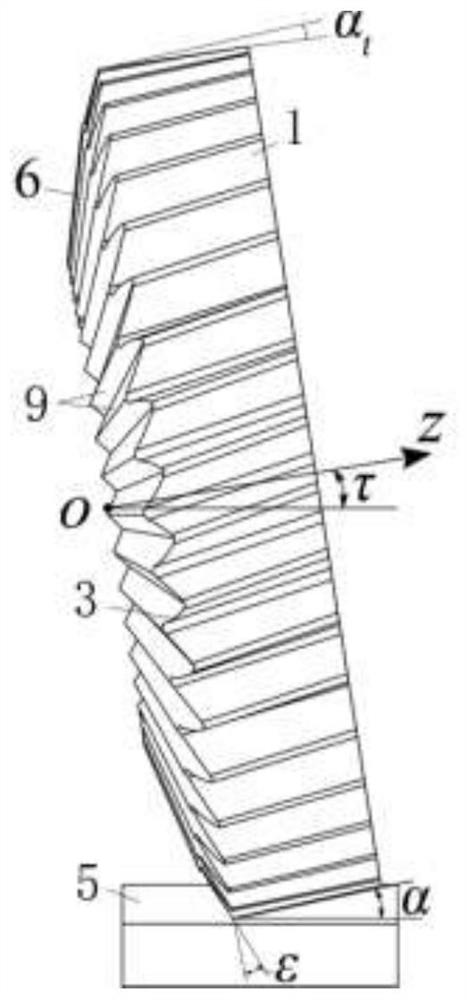

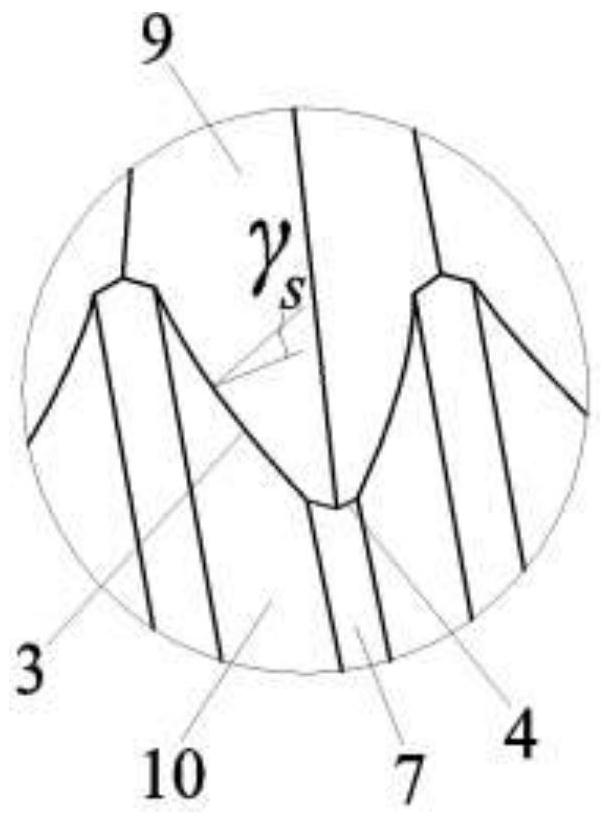

[0067] Considering the machinability of the material of the gear workpiece 5 and the structural strength of the tooth 2, the front angle of the cutting edge 3 on both sides of the tooth 2 is designed, the rear angle of the top edge 4 is designed, and the cone bottom angle of the convex tapered end face 6 is designed. 1 The basic parameters are shown in Table 2:

[0068] Table 2

[0069]

[0070] In this embodiment, the tooth profile and tooth direction modification of the gear workpiece 5 are both drum-shaped modification methods, C ρ (ρ) is the tooth profile drum modification function, referring to ISO drum modification, it can be expressed as:

[0071]

[0072] Among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com