Method and device for rapidly leaching out gold in waste circuit board

A waste circuit board, leaching technology, applied in the direction of improving process efficiency, etc., can solve the problems of increased recycling cost, long time consumption, slow reaction speed, etc., and achieve the effect of improving leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

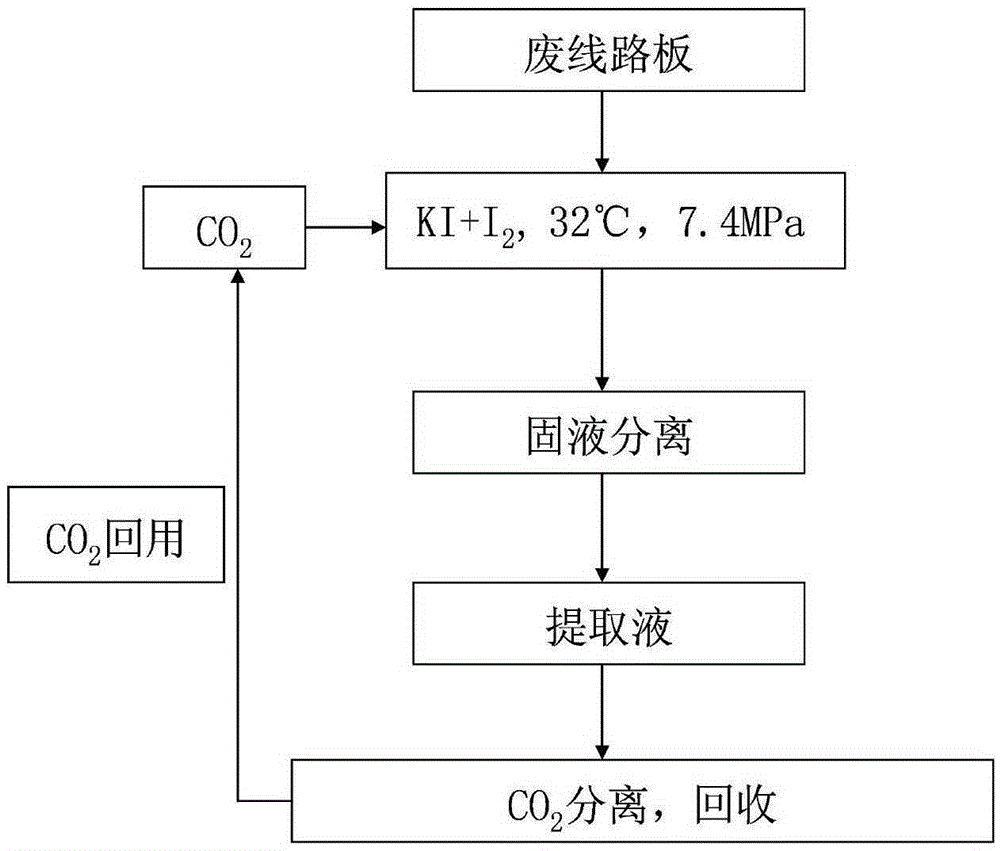

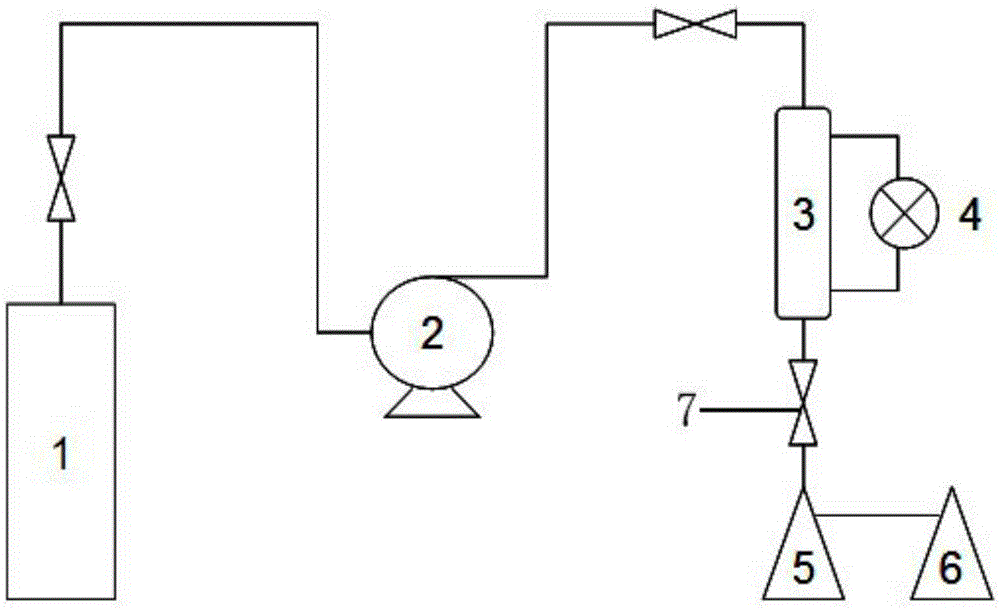

[0017] Such as figure 1 and figure 2 As shown, in step 1, the main board and components of the waste circuit board are separated, the components are sorted and processed separately, and the main board of the circuit board is processed into fragments smaller than 1cm by a shearing machine. First, pretreat the circuit board fragments with nitric acid, and the pretreatment conditions are as follows: the solid-to-liquid ratio is 1:15g / mL, and stirred in a constant temperature water bath at 60°C for 2h. After the pretreatment, the remaining residue is cleaned, filtered and dried, and then added to the reactor 3.

[0018] Add potassium iodide-iodine solution in reactor 3, wherein the molar concentration ratio n(I of iodine simple substance and potassium iodide 2 ):n(I - ) is 1:10, the solid-to-liquid ratio is controlled at 1:8g / mL, immediately seal the reactor 3, start the heater 4, start timing after the temperature rises to 32°C, and turn on the CO 2 Cylinder 1 and high-press...

Embodiment 2

[0020] Such as figure 1 and figure 2 As shown, the main board and components of the waste circuit board are separated, the components are sorted and processed separately, and the main board of the circuit board is processed into pieces smaller than 1cm by a shearing machine. First, pretreat the circuit board fragments with nitric acid, and the pretreatment conditions are as follows: the solid-to-liquid ratio is 1:15g / mL, and stirred in a constant temperature water bath at 60°C for 2h. After the pretreatment, the remaining residue is cleaned, filtered and dried, and then added to the reactor 3.

[0021] Add potassium iodide-iodine solution in reactor 3, wherein the molar concentration ratio n(I of iodine simple substance and potassium iodide 2 ):n(I - ) is 1:10, the solid-to-liquid ratio is controlled at 1:8g / mL, immediately seal the reactor 3, start the heater 4, start timing after the temperature rises to 32°C, and turn on the CO 2 Cylinder 1 and high-pressure pump 2, th...

Embodiment 3

[0023] Such as figure 1 and figure 2 As shown, the main board and components of the waste circuit board are separated, the components are sorted and processed separately, and the main board of the circuit board is processed into pieces smaller than 1cm by a shearing machine. First, pretreat the circuit board fragments with nitric acid, and the pretreatment conditions are as follows: the solid-to-liquid ratio is 1:15g / mL, and stirred in a constant temperature water bath at 60°C for 2h. After the pretreatment, the remaining residue is cleaned, filtered and dried, and then added to the reactor 3.

[0024] Add potassium iodide-iodine solution in reactor 3, wherein the molar concentration ratio n(I of iodine simple substance and potassium iodide 2 ):n(I - ) is 1:10, the solid-to-liquid ratio is controlled at 1:8g / mL, immediately seal the reactor 3, start the heater 4, start timing after the temperature rises to 32°C, and turn on the CO 2 Cylinder 1 and high-pressure pump 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com