A kind of uv adhesive for 3d printing casting molding and its application

A 3D printing and molding technology, applied in the direction of adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problems of time-consuming, complicated process, labor-intensive, etc., to save manpower, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

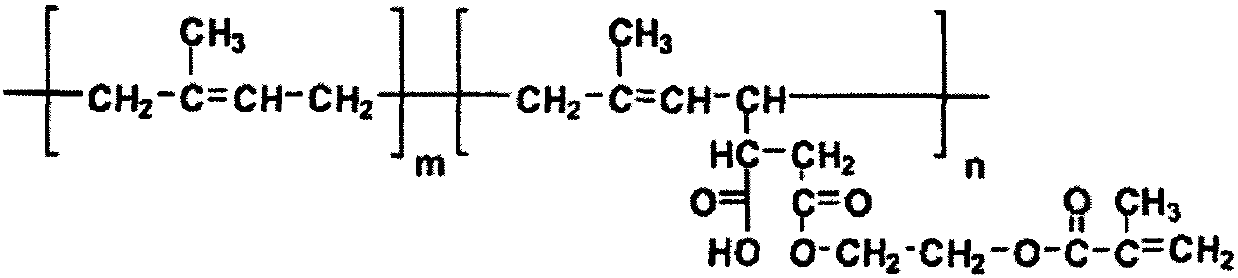

[0021] The UV adhesive used for 3D printing in this embodiment is a 100% solid-containing viscous liquid, and the adhesive contains at least the following substances by weight: Polyolefin UV oligomer: 25-80%, polyol acrylate Monomer: 10-50%, initiator: (184, 369) 1-10%, oxygen inhibitor (allyloxymethacrylate) 1-15%. The polymerized product of the polyolefin UV oligomer in this adhesive has excellent toughness and structural strength. In addition, initiators (184, 369) are specially added to this adhesive. This compound initiator can make the adhesive rapidly and accurately solidify on the 3D printing projection, and obtain the same model as the design drawing. In this embodiment, the molecular weight of the above-mentioned polyolefin UV oligomer is preferably controlled as: 15000-17000

[0022] Experiments have proved that when the molecular weight of polyolefin UV oligomer is in the above range, the structural strength and toughness can reach a perfect balance. Analysis of ...

Embodiment 2

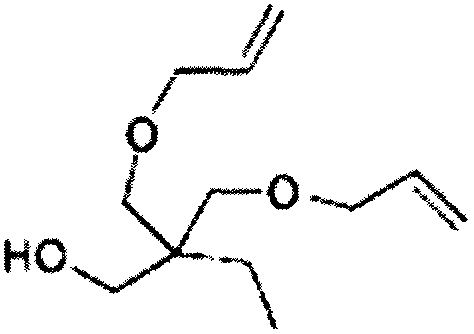

[0024] The difference between the adhesive of this embodiment and the embodiment 1 is that the adhesive further includes: a polyol acrylate monomer, the weight proportion of which is 10-50%. The polyol structural monomer has low temperature vaporization, and the addition of this component makes the cured product of the adhesive easier to lose wax casting.

Embodiment 3

[0026] The difference between the adhesive of the present embodiment and the embodiment 2 is that the adhesive also includes: an oxygen inhibitor (allyloxymethacrylate), the weight ratio of which is 1-15%. Oxygen barrier prevents the adhesive from cross-linking in an oxygenated environment. The addition of this component enables the adhesive to be printed with intermittent light 3D printers using mercury lamps and 405nm LED lamps as light sources, and can also meet continuous ultraviolet light irradiation. 3D printing mode.

[0027] The specific weight ratio of the adhesive of this embodiment is shown in the following table:

[0028] recipe

Weight ratio

Polyolefin UV oligomer

25~80%

10~50%

UV photoinitiators (184, 369)

1~10%

Oxygen inhibitor (allyloxymethacrylate)

1~15%

[0029] In conclusion, using the adhesives of the above embodiments, it is possible to perform intermittent 3D printing wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com