Composite material for 3D printing and production method therefor

A composite material and 3D printing technology, applied in the field of composite materials, can solve the problems that the mechanical strength and surface quality of 3D products do not meet the requirements, restrict 3D printing technology, reduce costs and other problems, achieve good dimensional stability, convenient production and manufacturing. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

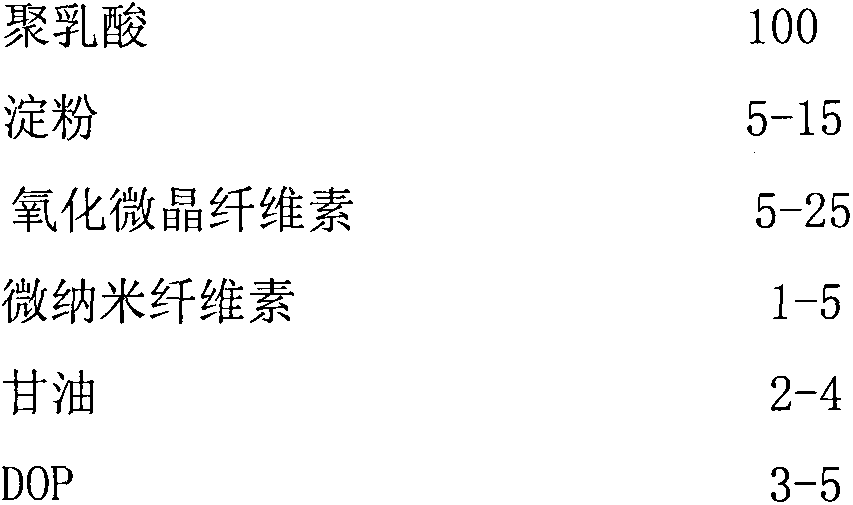

Embodiment 1

[0018]

[0019] ① Weigh a certain amount of microcrystalline cellulose and add it to a 7% sodium hydroxide solution, soak for 21 hours, filter with suction, wash with distilled water until neutral, dry in vacuum, and grind to obtain sodium hydroxide-treated microcrystalline cellulose;

[0020] ② Weigh 15 parts by weight of sodium hydroxide-treated microcrystalline cellulose and add it to 100 parts by weight of distilled water, and perform ultrasonic treatment for 3 hours. During the ultrasonic process, control the temperature of the treatment system at 35°C, and wash the treated microcrystalline cellulose fully with distilled water , suction filtration, vacuum drying, and grinding to obtain ultrasonically activated microcrystalline cellulose;

[0021] ③Add 100 parts by weight of distilled water into the reaction vessel, add 3 parts by weight of concentrated sulfuric acid and 1.1 parts by weight of concentrated nitric acid under stirring, and after mixing, quickly add ultras...

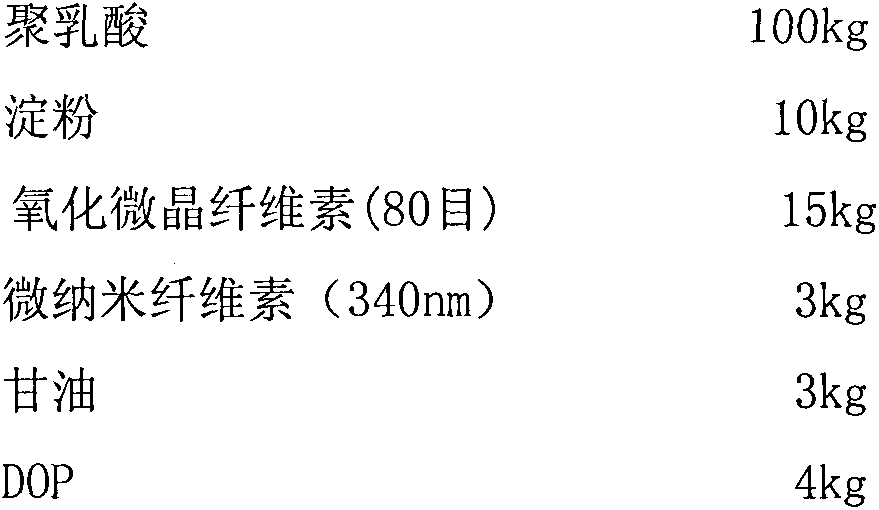

Embodiment 2

[0026]

[0027] ① Weigh a certain amount of microcrystalline cellulose and add it to a 4% sodium hydroxide solution, soak for 18 hours, filter with suction, wash with distilled water until neutral, dry in vacuum, and grind to obtain sodium hydroxide-treated microcrystalline cellulose;

[0028] ② Weigh 10 parts by weight of sodium hydroxide-treated microcrystalline cellulose and add it to 100 parts by weight of distilled water, and perform ultrasonic treatment for 2 hours. During the ultrasonic process, control the temperature of the treatment system at 30°C, and fully wash the treated microcrystalline cellulose with distilled water , suction filtration, vacuum drying, and grinding to obtain ultrasonically activated microcrystalline cellulose;

[0029] ③ Add 100 parts by weight of distilled water into the reaction vessel, add 3 parts by weight of concentrated sulfuric acid and 0.8 parts by weight of concentrated nitric acid while stirring, and after mixing, quickly add ultra...

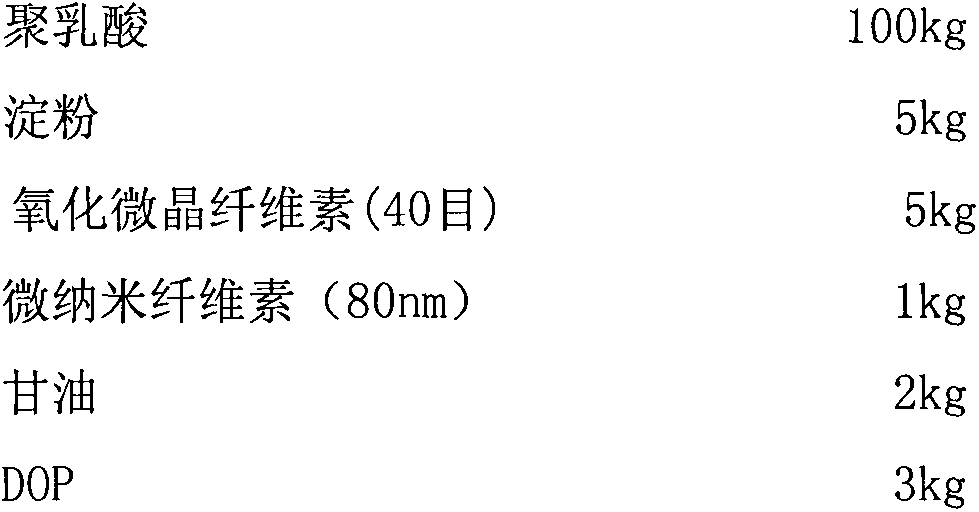

Embodiment 3

[0034]

[0035] ① Weigh a certain amount of microcrystalline cellulose and add it to 10% sodium hydroxide solution, soak for 24 hours, filter with suction, wash with distilled water until neutral, dry in vacuum, and grind to obtain microcrystalline treated with sodium hydroxide cellulose;

[0036] ② Weigh 20 parts by weight of sodium hydroxide-treated microcrystalline cellulose and add it to 100 parts by weight of distilled water, ultrasonically treat it for 4 hours, control the temperature of the treatment system at 40°C during the ultrasonic process, and wash the treated microcrystalline cellulose fully with distilled water , suction filtration, vacuum drying, and grinding to obtain ultrasonically activated microcrystalline cellulose;

[0037] ③Add 100 parts by weight of distilled water into the reaction vessel, add 3 parts by weight of concentrated sulfuric acid and 1.4 parts by weight of concentrated nitric acid while stirring, and after mixing, quickly add ultrasonical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com