Surface-modified silica/oxidized graphene nanocomposite and preparation method thereof

A nano-composite material and silicon dioxide technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve problems such as poor dispersion, limited graphene application, graphene easy to agglomerate, etc., to achieve organic The effect of good solubility, good product structure uniformity and regular material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

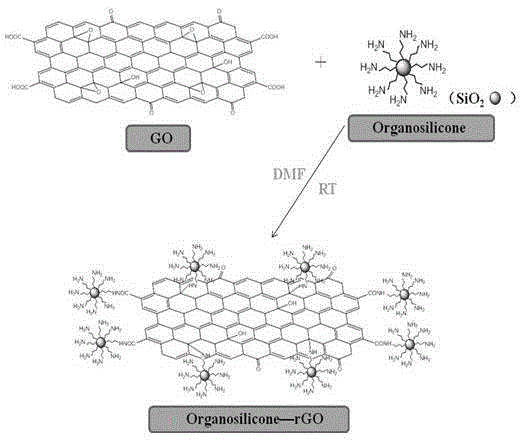

[0019] The preparation process of the silicon dioxide with amino groups used in the present invention can be found in Chinese patent ZL201210533104.X. The specific steps are: (1) TEOS and DMF are formulated into a mixed solution at a molar ratio of 1:6~1:12, (2) Measure 5~15ml of DMF and add ammonia water and KH550 to it, wherein the molar ratio of KH550 to TEOS obtained from the previous amount is 1:6~1:12, (3) Add the solution obtained in step (2) under the condition of mechanical stirring Add the solution obtained in step (1) dropwise to the solution, and continue stirring for 8-10 hours after the dropwise addition to prepare the organic silica sol with amino groups.

[0020] (1) Take 3.8ml (0.15mol) TEOS, dissolve it in 30ml (1.65mol) of DMF, and prepare a mixed solution; (2) Take 10ml of DMF in a three-necked flask, add 0.468ml (0.040mol) of KH550 and 0.48ml of ammonia water to make a mixed solution; (3) Mechanically stir the solution of (2), at the same time add the mixe...

Embodiment 1

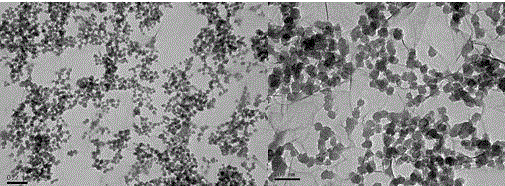

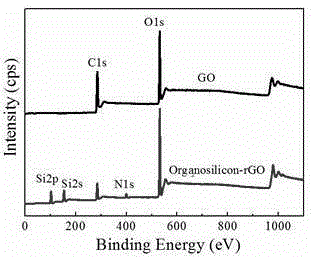

[0023] First add 25ml of DMF to a 100ml single-necked flask, then add 1.2ml of silica sol with amino groups and sonicate for 20 minutes to obtain a dilute organic silica sol solution. Take a 100ml single-necked flask and add 40ml of DMF, and then add 20mg of graphene oxide for ultrasonic dispersion for 2 hours. Use a constant pressure dropping funnel to add the diluted organosilicon sol DMF solution at a rate of 1 to 3 drops per second to the continuously stirred dilute graphene oxide DMF solution at room temperature. , stirred and reacted for 1h, then ultrasonically dispersed for 30min, then continued to stir at room temperature for 10~12h, after the end of the reaction, ultrasonically for 1h, then filtered with a 220nm organic filter, washed with DMF, and then dispersed in 100ml DMF by ultrasonic, and then filtered by suction Repeat this process 3 times until the excess organosilica spheres are removed to obtain the organosilicon sol-reduced graphene oxide composite material,...

Embodiment 2

[0025] First add 15ml of DMF to a 100ml single-necked flask, then add 0.7ml of organic silica sol with amino groups and ultrasonically 20min to obtain a dilute solution of organic silica sol, take a 100ml single-necked flask, add 40ml of DMF, and then add 20mg of graphene oxide for ultrasonic dispersion for 2h. Add the sonicated organic silica sol dilute solution dropwise to the continuously stirred dilute graphene oxide solution at room temperature, stir for 1 hour, then ultrasonically disperse for 30 minutes, then continue to stir and react at room temperature for 10~12 hours, and then sonicate for 1 hour after the reaction. Afterwards, filter with a 220-nanometer organic membrane, wash with DMF, and then disperse in 100ml DMF with ultrasound, and repeat this process 3 times until the excess organosilica balls are removed, and the organosilica sol-reduced graphene oxide is obtained. Composite material, black powder solid can be obtained by drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com