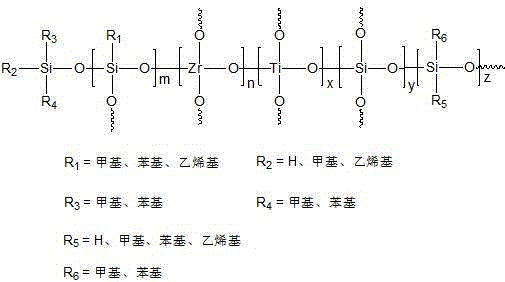

Hybrid organic silicon resin with framework structure containing Zr or containing Zr and Ti simultaneously and preparation method of organic silicon resin

A skeleton structure, silicone technology, applied in the field of silicone resin and its preparation, can solve the problems of large ternary sulfur ring tension, long polymerization induction period, unsuitable for packaging, etc., and achieve superior weather resistance and high and low temperature resistance, The synthetic method is simple and easy, and the effect of being easy to industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Put 25.2g of vinyl MT silicone resin (number average molecular weight 830), 200g of toluene, 0.1g of concentrated sulfuric acid and 8.0g of water into a three-necked flask, slowly add 84.11g of zirconium n-butoxide dropwise. The dehydration condensation reaction was carried out for 6 hours. After the reaction, wash with water to remove the catalyst in the system, dry and filter the organic phase washed to neutrality, and then remove the solvent and small molecular substances by vacuum rotary evaporation to obtain 45.8 g of transparent titanium-containing silicone resin with a refractive index of 1.67 / 25°C.

Embodiment 2

[0026] Put 50.0g of MQ silicone resin containing Si-H groups (number average molecular weight is 1308), 34.6g of zirconium isopropoxide and 120g of toluene into a three-necked flask, slowly add a mixture of 0.2g of potassium hydroxide and 4.5g of water, dropwise After the addition was completed, the dehydration condensation reaction was carried out at 110° C. for 5 hours. After the reaction, wash with water to remove the catalyst in the system, dry and filter the washed neutral organic phase, and then vacuum rotary evaporation to remove the solvent and small molecular substances to obtain 59.2 g of transparent titanium-containing silicone resin, the resin refractive index is 1.56 / 25°C.

Embodiment 3

[0028] Put 25.0g of vinylphenyl-containing MDT silicone resin (the number average molecular weight is 560), 112.74g of zirconium tert-butoxide and 180g of toluene into a three-necked flask, slowly add a mixture of 0.3g of potassium hydroxide and 10.6g of water, drop After the addition was completed, the dehydration condensation reaction was carried out at 110° C. for 8 hours. After the reaction, wash with water to remove the catalyst in the system, dry and filter the organic phase washed to neutrality, and then remove the solvent and small molecular substances by vacuum rotary evaporation to obtain a transparent titanium-containing silicone resin. 56.6g, the resin refractive index is 1.72 / 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com