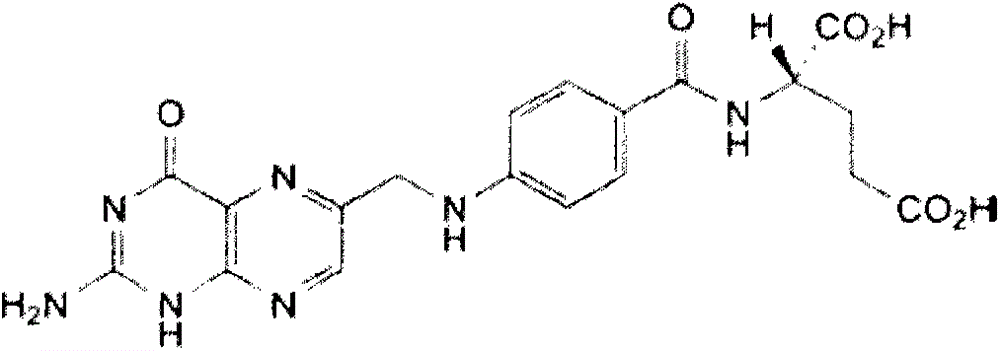

Folic acid solid dispersion body and preparation method thereof

A technology of solid dispersion and solid preparation, which is applied in the field of medicine to achieve the effects of easy industrial scale-up, good dissolution behavior and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

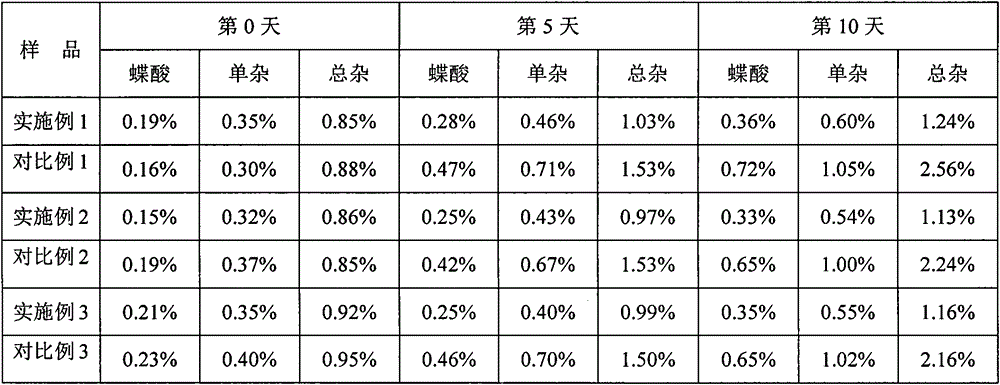

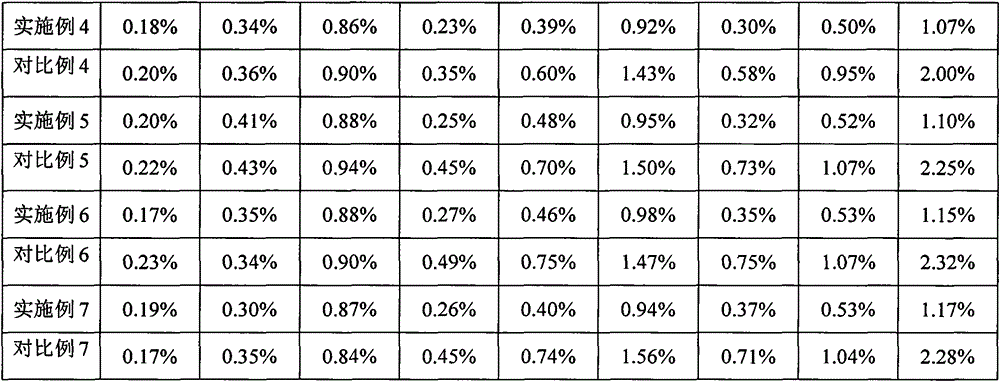

Examples

Embodiment 1

[0037] Preparation of folic acid solid dispersion:

[0038] prescription:

[0039] Raw materials

Dosage

folic acid

100g

Poloxamer 188

500g

[0040] Process:

[0041] 1) Weigh the prescribed amount of folic acid and poloxamer 188, first melt the poloxamer 188 completely at 65°C, then add folic acid, and stir until completely melted;

[0042] 2) Rapidly cooling the completely melted folic acid and hydrophilic carrier obtained in 1) in an ice bath and under stirring conditions until they are completely solidified, and then frozen at -15°C for 4 hours;

[0043] 3) Take the material obtained in 2) after freezing, dry it at 35° C. for 2 hours, take it out, crush and sieve the material within the range of 80-150 meshes, and obtain the folic acid solid dispersion.

Embodiment 2

[0045] Preparation of folic acid solid dispersion:

[0046] prescription:

[0047] Raw materials

Dosage

folic acid

100g

polyethylene glycol 6000

1000g

[0048] Process:

[0049] 1) Weigh the prescribed amount of folic acid and polyethylene glycol 6000, first melt the polyethylene glycol 6000 completely at 80°C, then add folic acid, and stir until completely melted;

[0050] 2) Rapidly cooling the completely melted folic acid and the hydrophilic carrier obtained in 1) in an ice bath and stirring until completely solidified, and then freezing at -25°C for 6 hours;

[0051] 3) Take the material obtained in 2) after freezing, dry it at 45°C for 6 hours, take it out, crush and sieve the material within the range of 80-150 meshes, and obtain the folic acid solid dispersion.

Embodiment 3

[0053] Preparation of folic acid solid dispersion:

[0054] prescription:

[0055] Raw materials

Dosage

folic acid

100g

Poloxamer 188

1500g

polyethylene glycol 4000

1500g

[0056] Process:

[0057] 1) Weigh the prescribed amount of folic acid and hydrophilic carrier, first melt the carrier completely at 70°C, then add folic acid, and stir until completely melted;

[0058] 2) Rapidly cooling the completely melted folic acid and hydrophilic carrier obtained in 1) in an ice bath and under stirring until completely solidified, and then freezing at -20°C for 8 hours;

[0059] 3) Take the material obtained in 2) after freezing, dry it at 40°C for 4 hours, take it out, crush and sieve the material within the range of 80-150 meshes, and obtain the folic acid solid dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com