Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of weak humidity resistance and poor humidity stability, and achieve the effects of high humidity stability, easy control, and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

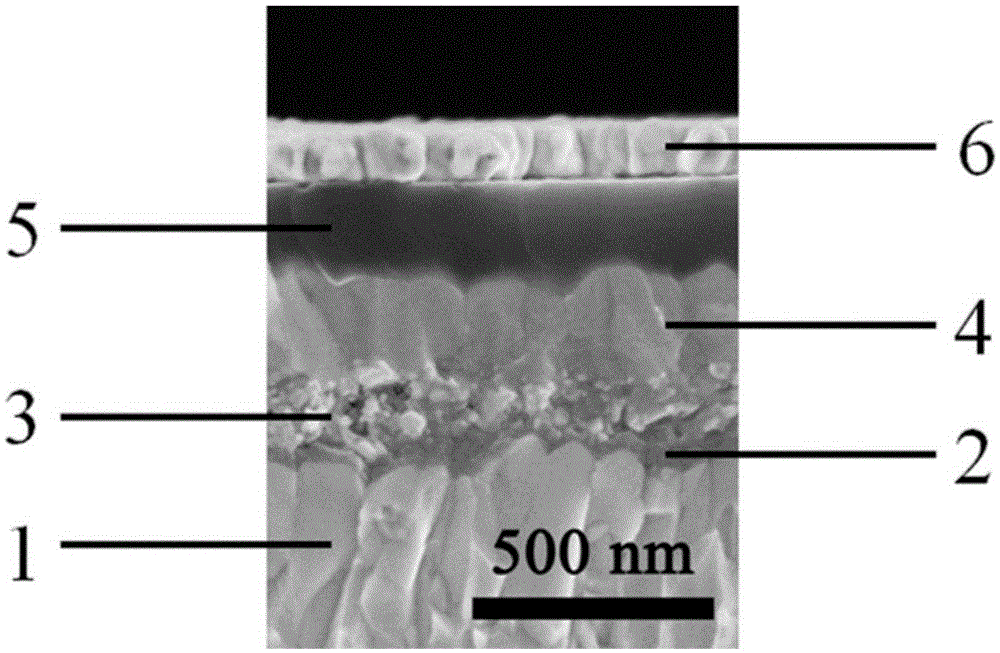

[0027] Use FTO conductive glass as the substrate 1; dilute titanium isopropoxide coordinated with acetylacetone 10 times with ethanol, take 1.2mL of the diluted solution and divide it into three times on average, and under the condition of the substrate temperature of 450°C, use oxygen as The carrier is subjected to spray pyrolysis to obtain a dense titanium dioxide layer 2 .

[0028] Dilute the titanium dioxide slurry (18NRT, Dyesol) and ethanol according to the mass ratio of 1:6 and mix them evenly. Take 50 μL of the diluted titanium dioxide slurry, set the speed of the homogenizer at 5000r / min for 30s, and then spin-coat the obtained The film was dried and sintered at temperatures of 80°C, 125°C, 350°C and 500°C in sequence, and the duration of each temperature was 30 minutes; non-titanium dioxide substances in the film were removed to obtain a porous titanium dioxide layer 3 composed of titanium dioxide nanoparticles.

[0029] Drop 50 μL of the dimethylformamide mixed solu...

Embodiment 2

[0034] The difference between Example 2 and Example 1 is that when preparing the perovskite-type light-absorbing layer material, a dimethylformamide solution with a concentration of 462 mg / mL of lead iodide and 52 mg / mL of cesium iodide is used, Then doped formamidine lead iodide was prepared to assemble perovskite solar cells.

[0035] After testing, the photoelectric conversion efficiency of the perovskite solar cell prepared by doping formamidine lead iodide with this concentration of cesium ions reaches 12.4%. After using a constant temperature and humidity box to age this device, the aging conditions are 50% humidity and 20°C. After 100 hours, the photoelectric conversion efficiency of the solar cell remains at about 4.8%, and the humidity stability is stronger than that of undoped calcium titanium. Mine solar cells.

Embodiment 3

[0037] The difference between Example 3 and Example 1 and Example 2 is: when preparing the perovskite type light-absorbing layer material, the dimethyl formamide solution, and then prepare doped formamidine lead iodide to assemble perovskite solar cells.

[0038] After testing, the photoelectric conversion efficiency of the perovskite solar cell prepared by doping formamidine lead iodide with this concentration of cesium ions reaches 8.54%. After using a constant temperature and humidity box to age this device, the aging conditions are 50% humidity and 20°C. After 100 hours, the photoelectric conversion efficiency of the solar cell remains at about 3.4%, and the humidity stability is stronger than that of undoped calcium titanium. Mine solar cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com