Environment-friendly building waterproof paint with low content of VOC and preparation method thereof

A waterproof and environmentally friendly technology for buildings, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as accelerated material aging, ecological system damage, and damage to human health, and achieve rheological performance improvement , Improve low temperature flexibility, improve the effect of synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

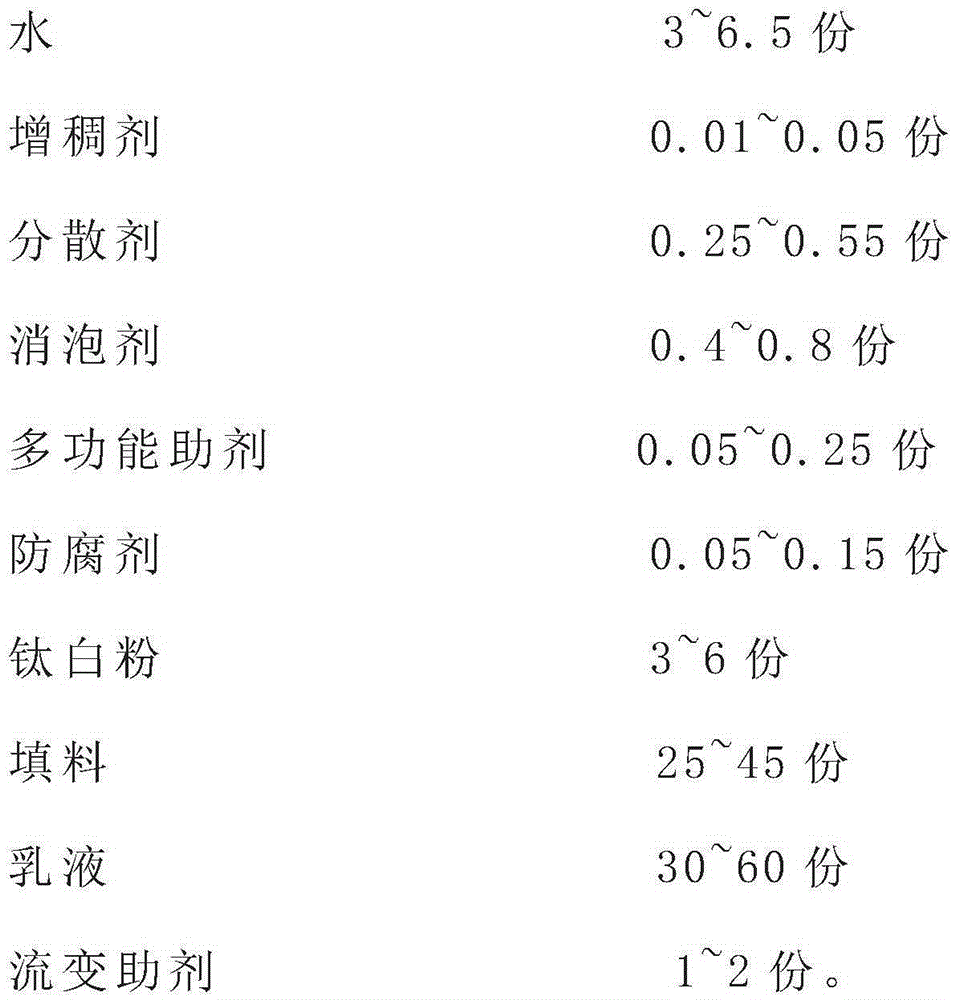

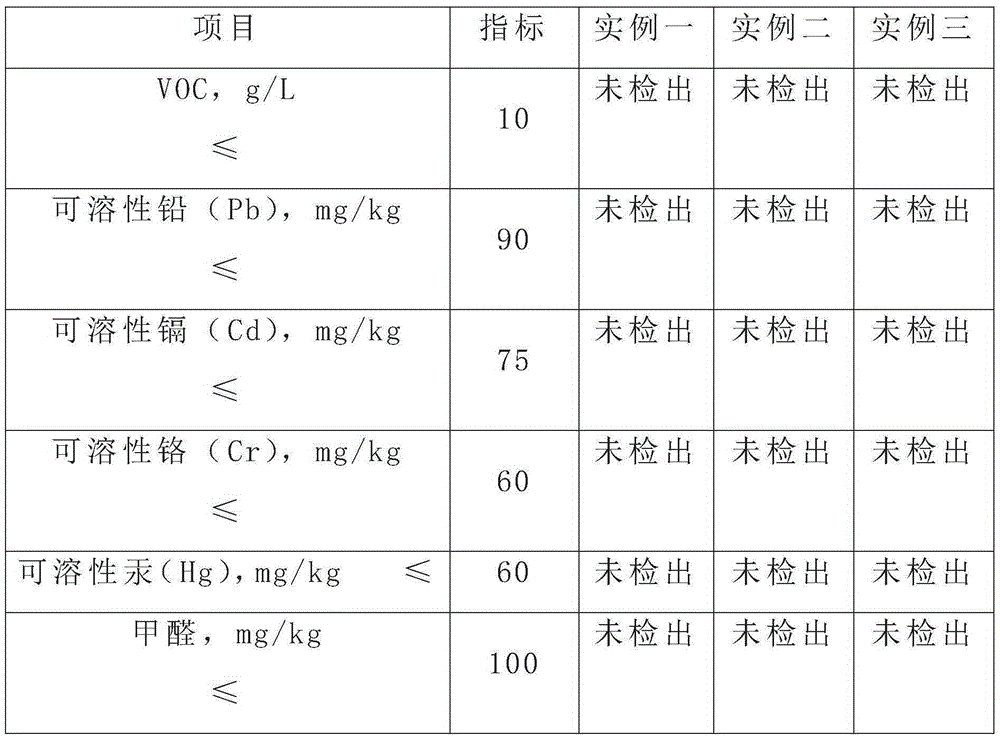

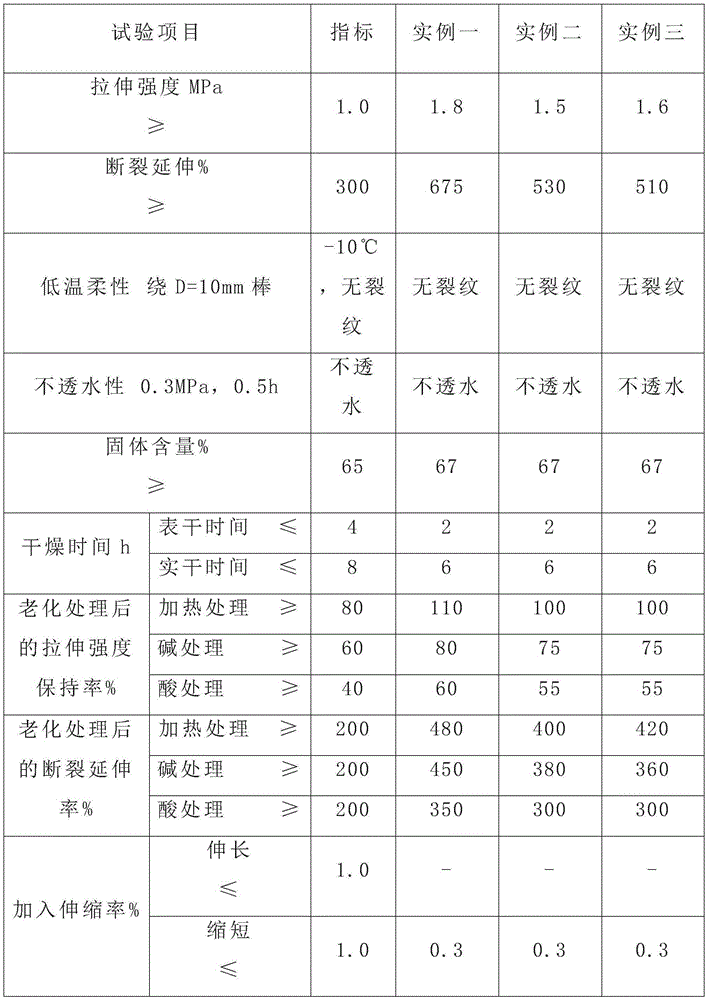

[0038] A kind of low VOC environmental protection building waterproof coating, its preparation method is as follows:

[0039]Add 3 parts of water into the container, disperse with a disperser at a suitable speed, add 0.01 part of thickener (BERMOCOLLEHM300, a composite non-ionic water-soluble cellulose ether) to completely dissolve, and continue to add 0.25 parts in sequence 5040 polycarboxylate dispersant, 0.4 parts of defoamer (SPA202 and DFC17 compounded at 1:1), 0.05 parts of multifunctional additive (AMP-95), and then add 3 parts of titanium dioxide, 25 parts of filler (including weight 10 parts of calcium carbonate, 10 parts of barite powder, and 5 parts of talc powder), and disperse to the required fineness to obtain a dispersion slurry.

[0040] Mix 0.4 parts of defoamer (SPA202 and DFC17 compounded at 1:1), 30 parts of emulsion (including 20 parts of low-VOC pure acrylic emulsion, 9 parts of low-VOC vinyl acetate-ethylene emulsion, soap-free silicone rubber) at a cert...

Embodiment 2

[0042] A kind of low VOC environmental protection building waterproof coating, its preparation method is as follows:

[0043] Add 4.5 parts of water into the container, disperse with a disperser at a suitable speed, add 0.03 parts of thickener (BERMOCOLLEHM300, a composite non-ionic water-soluble cellulose ether) to completely dissolve, and continue to add 0.35 parts in sequence 5040 polycarboxylate dispersant, 0.6 parts of defoamer (SPA202 and DFC17 compounded at 1:1), 0.1 part of multifunctional additive (AMP-95), and then add 4.5 parts of titanium dioxide, 35 parts of filler (wherein weight 10 parts of calcium carbonate, 20 parts of barite powder, and 5 parts of talc powder), and disperse to the required fineness to obtain a dispersion slurry.

[0044] Mix 0.2 parts of defoamer (SPA202 and DFC17 compounded at 1:1), 55 parts of emulsion (including 25 parts of low-VOC pure acrylic emulsion, 29 parts of low-VOC vinyl acetate-ethylene emulsion, soap-free silicone rubber) at a c...

Embodiment 3

[0046] A kind of low VOC environmental protection building waterproof coating, its preparation method is as follows:

[0047] Add 6.5 parts of water into the container, disperse with a disperser at a suitable speed, add 0.05 parts of thickener (BERMOCOLLEHM300, a composite non-ionic water-soluble cellulose ether) to completely dissolve, and continue to add 0.55 parts in sequence 5040 polycarboxylate dispersant, 0.6 parts of defoamer (SPA202 and DFC17 compounded at 1:1), 0.25 parts of multifunctional additive (AMP-95), and then add 6 parts of titanium dioxide, 45 parts of filler (wherein weight 30 parts of calcium carbonate, 10 parts of barite powder, and 5 parts of talc powder), and disperse to the required fineness to obtain a dispersion slurry.

[0048] Mix 0.2 parts of defoamer (SPA202 and DFC17 compounded at 1:1), 60 parts of emulsion (including 20 parts of low-VOC pure acrylic emulsion, 39 parts of low-VOC vinyl acetate-ethylene emulsion, soap-free silicone rubber) at a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com