Dual-curing peelable aqueous coating material and preparation method thereof

A dual-curing, water-based coating technology, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of not being easy to cure completely, and achieve easy control, good peelability, and short drying time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

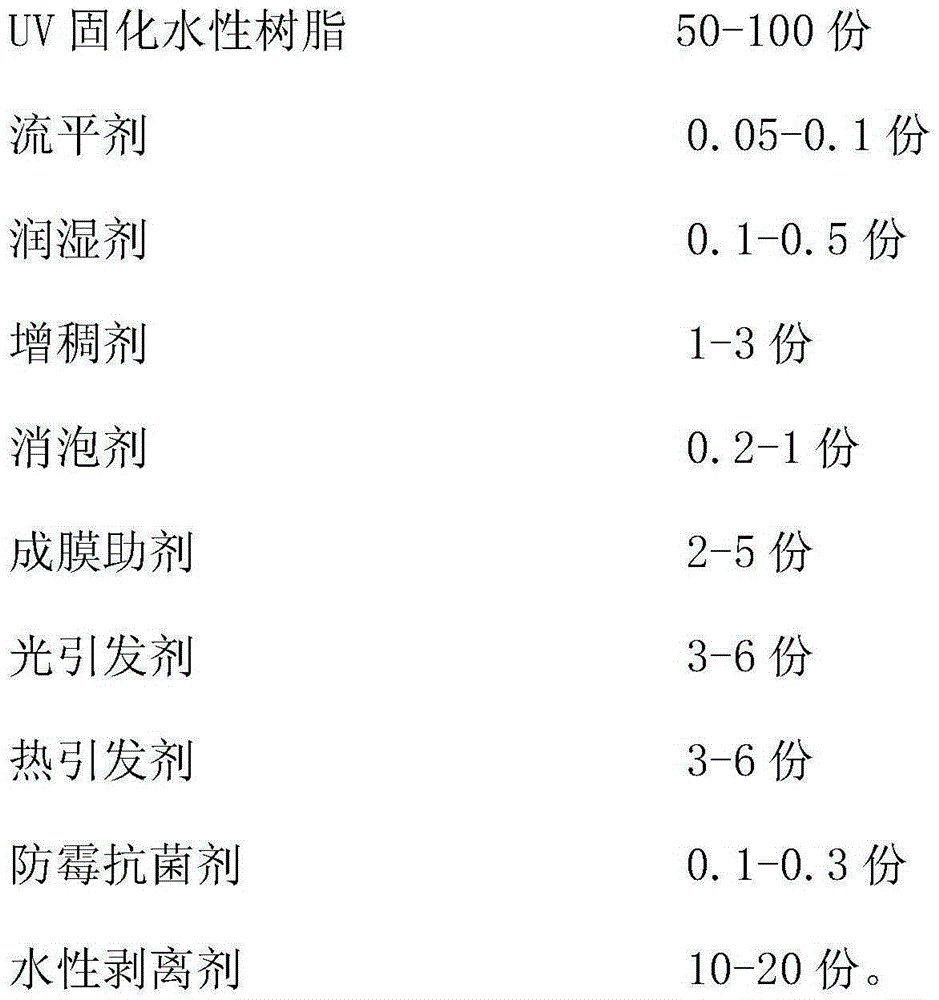

Method used

Image

Examples

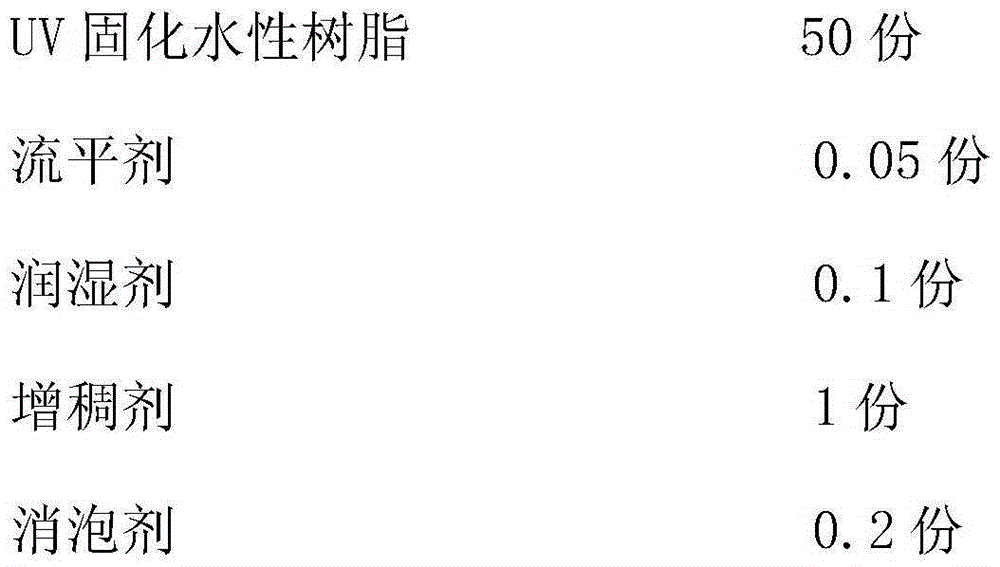

Embodiment 1

[0042] A dual-curing peelable water-based paint, calculated in parts by weight, its raw material composition and content are as follows:

[0043]

[0044] Wherein, the UV curable water-based resin is the JAZO emulsion of Nanjing Jiazhong Chemical Technology Co., Ltd.;

[0045] Described thermal initiator is dibenzoyl peroxide;

[0046] Described photoinitiator is the aqueous photoinitiator 819-DW that Tianjin Heinz Technology Development Co., Ltd. provides;

[0047] The anti-mildew and antibacterial agent is XK-02B of Nantong Boda Biochemical Co., Ltd. formula;

[0048] The leveling agent is BYK346 of BYK Company;

[0049] Described wetting agent is the NP-100 of U.S. Dow Company;

[0050] Described thickening agent is the RM825 of Rohm and Haas Co., Ltd.;

[0051] Described defoamer is the NopcoNXZ of German Henkel Company;

[0052] Described film-forming aid is the dipropylene glycol butyl ether of U.S. Dow Chemical Company;

[0053] The water-based stripping agent ...

Embodiment 2

[0060] A dual-curing peelable water-based paint, calculated in parts by weight, its raw material composition and content are as follows:

[0061]

[0062] Wherein, the UV curable water-based resin is the JAZO emulsion of Nanjing Jiazhong Chemical Technology Co., Ltd.;

[0063] The thermal initiator is azobisisobutyronitrile;

[0064] Described photoinitiator is the aqueous photoinitiator 819-DW that Tianjin Heinz Technology Development Co., Ltd. provides;

[0065] The anti-mildew and antibacterial agent is XK-02B of Nantong Boda Biochemical Co., Ltd. formula;

[0066] The leveling agent is German BYK BYK-UV3510;

[0067] Described wetting agent is the NP-100 of U.S. Dow Company;

[0068] The thickener is the RM-8W water-based nonionic associative rheology modifier provided by Guangzhou Hengyu Chemical Co., Ltd.;

[0069] Described defoamer is the NopcoNXZ of German Henkel Company;

[0070] Described film-forming aid is the dipropylene glycol butyl ether of U.S. Dow Che...

Embodiment 3

[0078] A dual-curing peelable water-based paint, calculated in parts by weight, its raw material composition and content are as follows:

[0079]

[0080]

[0081] The preparation method of this dual curing peelable water-based coating specifically comprises the steps:

[0082] According to the formula, add 0.15 parts of wetting agent, 0.3 parts of defoamer and 40ml of deionized water into the GFJ-0.4 high-speed disperser (Shanghai Xinnuo Instrument Equipment Co., Ltd.), disperse at 700r / min for 18min, and then Add 16 parts of water-based stripping agent, disperse at 2000r / min for 40 minutes, then reduce the speed to 300r / min, add 80 parts of UV-curable water-based resin and the remaining 0.3 parts of defoamer, 0.15 parts of wetting agent and 2 parts of enhancer Thickener, 0.06 parts of leveling agent, 3 parts of film-forming aid, 4 parts of thermal initiator, 4 parts of photoinitiator, 0.2 part of anti-corrosion and anti-fungal agent and stir well, continue to disperse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com