Production equipment and technique for plate-strip dual-use continuous production straight-slit submerged-arc welded pipes

A technology of straight seam submerged arc welding and production equipment, which is applied in the direction of arc welding equipment, welding equipment, and other manufacturing equipment/tools. The effect of small amount and low residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

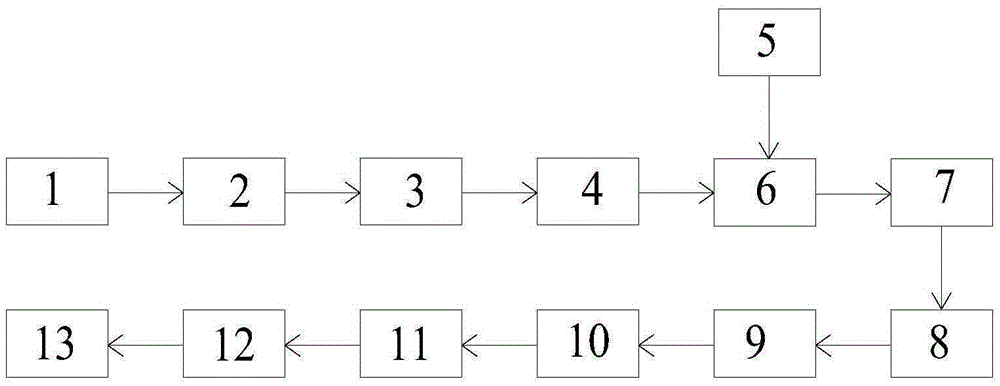

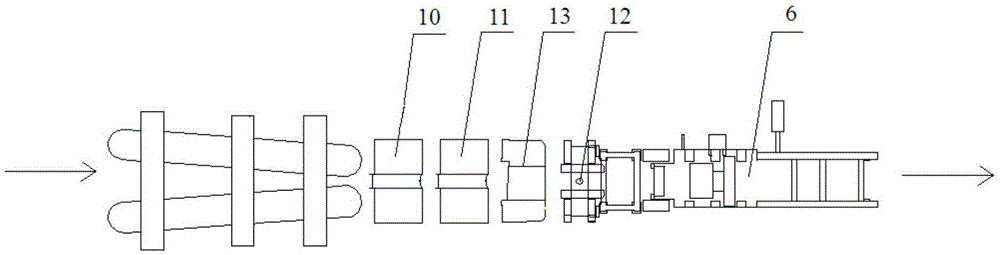

[0037] Such as Figure 1-6As shown, the production equipment for continuous production of longitudinal submerged arc welded pipes for dual-purpose plates and strips includes material preparation table 1, decoiler 2, leveling machine 3, plate shearing machine 4, plate automatic feeding machine 5, and plate edge derusting machine 6. Edge milling machine 7, C-type machine 8, O-type machine 9, sizing machine 10, joint pre-welding equipment 11, cutting device 12, post-processing device 13.

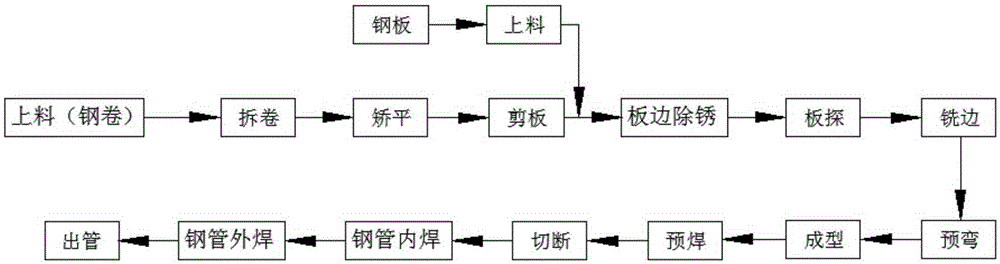

[0038] A production process for continuous production of straight seam submerged arc welded pipes for dual-purpose plates and strips, such as figure 1 As shown, in the specific operation, the material is first loaded through the material preparation table. When loading:

[0039] When feeding with steel coils: first conduct the steel coil size and appearance inspection, then use the multi-station coil preparation table to provide steel coils through the coiling trolley, uncoil the uncoiler 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com