Rollover-type iron charging transport vehicle

The technology of a transport vehicle and a tipping frame is applied in the field of tipping-type iron mixing transport vehicles, which can solve the problems of smoke and dust release, environmental pollution, danger, etc., and achieve the effects of increasing steel output, reducing production costs, and having a reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

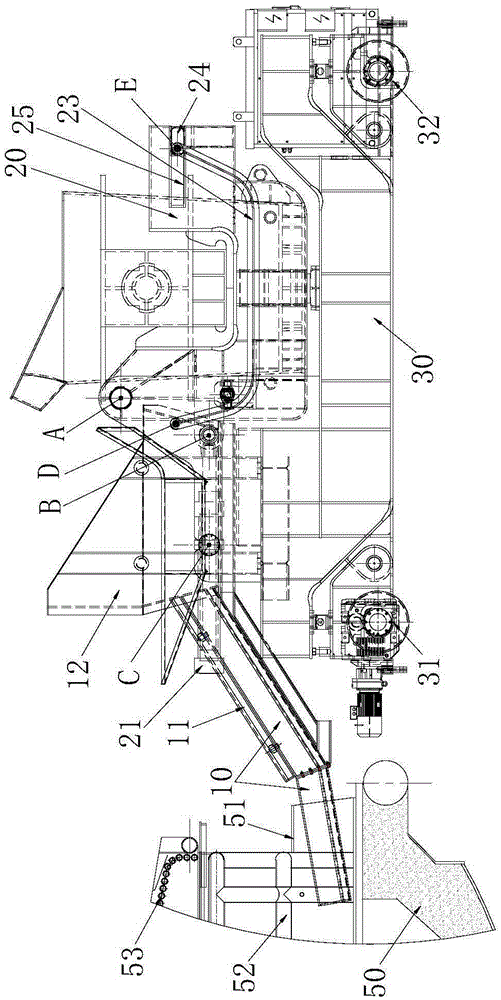

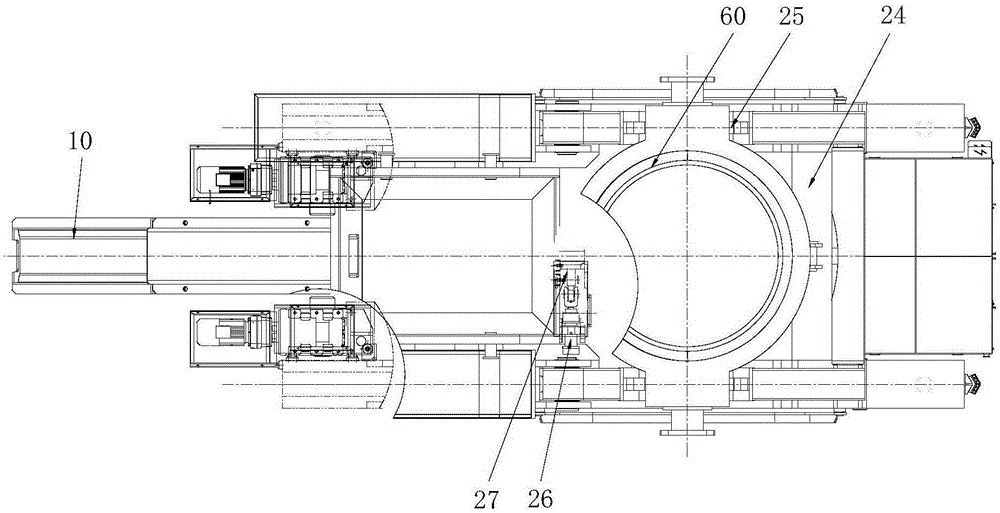

[0037] Such as figure 1 As shown, the electric furnace 50 is provided with a water-cooled furnace wall 52 positioned at the side of the electric furnace and a water-cooled furnace cover 53 positioned at the top of the electric furnace. The prior art is to open the water-cooled furnace cover 53 and pour molten iron into the electric furnace, which will not only produce a large amount of smoke and dust to be released into the electric furnace. In the atmosphere, molten iron will also be splashed out and pollute the environment. To solve this problem, the present invention provides a tilting type mixing iron transport vehicle, which can mix molten iron into the electric furnace 50, and Including drainage tank 10, driving device, veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com