Ozone catalyst and preparation method thereof

A catalyst, ozone technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of expensive metal oxides and environmental impact, achieve low cost, enhance adsorption performance, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

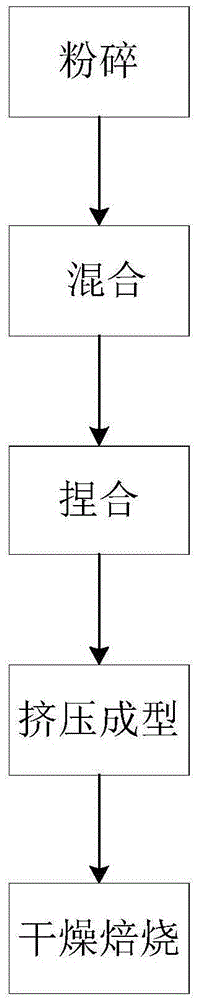

[0026] A kind of preparation method of ozone catalyst, comprises the steps:

[0027] (1) Manganese sand filter material (the content of manganese dioxide is 20%, and the content of iron is 25%) is pulverized, and the grinding fineness is 50 orders; Get 100g of manganese sand filter material fine powder, add particle diameter and be 1 μm, moisture 20g of starch with a content of 0.01%, stir and mix evenly;

[0028] (2) Add 6 g of acetic acid and 1.2 g of water to the mixed powder and mix evenly, then knead for 1 min;

[0029] (3) After kneading, extrude into strips with a diameter of 2mm and a length of 10mm;

[0030] (4) Then dry at 80°C for 2 hours, and then bake at 1000°C for 2 hours in air to obtain a finished product.

Embodiment 2

[0032] A kind of preparation method of ozone catalyst, comprises the steps:

[0033] (1) pulverizing the pyrolus ore (the content of manganese dioxide is 45%), and the pulverizing fineness is 100 orders; get 200g of pyrolus ore fine powder, add the attapulgite 80g that particle diameter is 50 μm, moisture content is 0.1% , stir and mix evenly;

[0034] (2) Add 14g of citric acid and 2.8g of water to the mixed powder and mix evenly, then knead for 10min;

[0035] (3) After kneading, extrude into strips with a diameter of 3mm and a length of 5mm;

[0036] (4) Then dry at 90°C for 4 hours, and then bake at 800°C for 2 hours in air to obtain a finished product.

Embodiment 3

[0038] A kind of preparation method of ozone catalyst, comprises the steps:

[0039] (1) Manganese sand filter material (the content of manganese dioxide is 30%, and the content of iron is 20%) is pulverized, and the grinding fineness is 200 orders; Get 100g of manganese sand filter material fine powder, add particle diameter and be 50 μm, moisture 60g of diatomite with a content of 0.2%, stir and mix evenly;

[0040] (2) Add 1.6g of water to the mixed powder and mix evenly, then knead for 3min;

[0041] (3) After kneading, extrude into strips with a diameter of 4mm and a length of 7mm;

[0042] (4) Then dry at 100°C for 3 hours, and then bake at 500°C for 5 hours in air to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com