Flexible multifunctional sensor, preparation method and application thereof

A sensor, multifunctional technology, used in the field of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

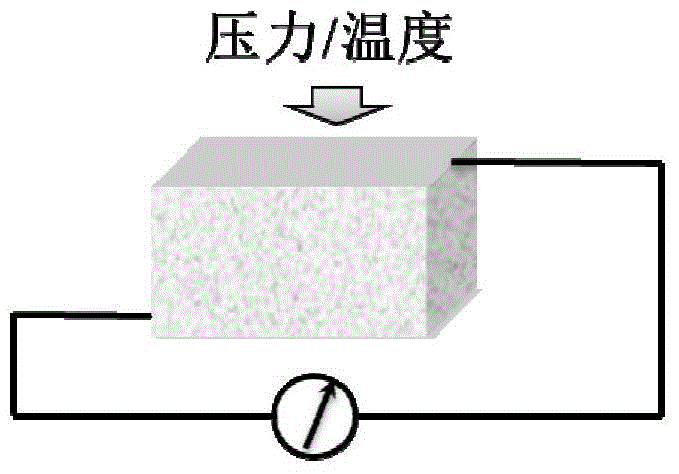

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 (preparation of single device)

[0054] 1) Select a sponge with a thickness of 5mm, and cut the sponge with a fixed size (3.5mm×3.5mm×5mm);

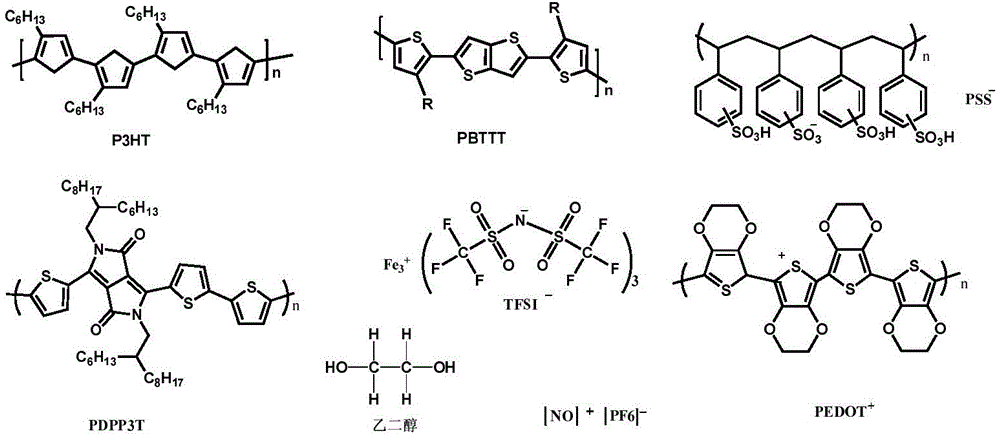

[0055] 2) Prepare a PEDOT-PSS solution doped with 5% volume fraction of ethylene glycol (the PEDOT-PSS model is PH1000, the mass ratio of PEDOT to PSS is 1:2.5, and the number average molecular weight of PEDOT is 50000), soak the sponge in it to obtain Sponge-PEDOT composite system material doped with thermoelectric materials, as a flexible composite material layer of the sensor, with a thickness of 5mm;

[0056] 3) After the glass sheet with a thickness of 1.2mm is ultrasonically rinsed with secondary water, ethanol and acetone, and blown dry with nitrogen, the vacuum degree is 7×10 -4 Under the condition of Pa The speed is vapor-deposited gold on the glass sheet, the thickness is 60nm, obtains the lower electrode layer;

[0057] 4) Fix the sponge obtained in step 2) on the lower electrode layer obtained in step ...

Embodiment 2

[0078] According to the method of Example 1, only the PEDOT-PSS doped with ethylene glycol in step 2) is replaced by doped NOPF 6 PBTTT (molar mass is 34000g / mol), first soak the sponge in the PBTTT solution with a concentration of 10mg / mL, dry it in NOPF 6 The concentration is 0.01mol / L of acetonitrile solution soaked for 1 to 10 minutes, and then dried again to obtain sponge-PBTTT composite materials with different doping degrees, and obtain the multifunctional sensor provided by the present invention.

[0079] The structure of the device is the same as that obtained in Example 1, the only difference is that the thermoelectric material used in the composite material system is replaced by doped NOPF 6 The PBTTT.

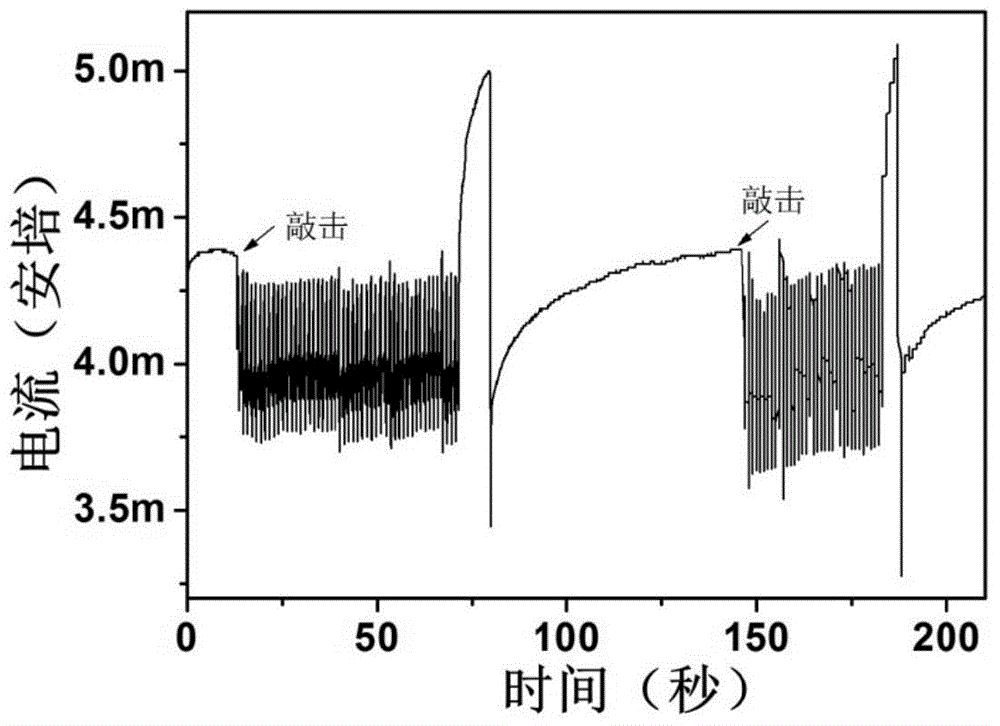

[0080] The device is used to detect pressure and temperature and perform multifunctional sensing tests under self-powered conditions. The results obtained are not substantially different from those in Example 1, and will not be repeated here.

Embodiment 3

[0082] According to the method of Example 1, only the PEDOT-PSS solution doped with ethylene glycol in step 2) is replaced by doped Fe(TFSI) 3 P3HT (molar mass is 18000g / mol), soak the sponge in the P3HT solution with a concentration of 10mg / mL, dry it and soak it in Fe(TFSI) 3 The concentration is 0.1 mol / L acetonitrile solution for 5 to 20 minutes, and after drying again, sponge-P3HT composite materials with different doping degrees are obtained, and the multifunctional sensor provided by the invention is obtained.

[0083] The structure of the device is the same as that obtained in Example 1, the only difference is that the thermoelectric material used in the composite material system is replaced by doped Fe(TFSI) 3 P3HT.

[0084] The device is used to detect pressure and temperature and perform multifunctional sensing tests under self-powered conditions. The results obtained are not substantially different from those in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com