Ceramic anode oxidation solution and ceramic anode oxidation process

An anodizing and ceramic technology, applied in the direction of anodizing, can solve the problem of no ceramic anodizing solution, not as hard as ceramic anodizing, etc., and achieve the effect of expanding the range of surface decoration color, maintaining the surface enamel feeling, and simple process conditions.

Inactive Publication Date: 2016-03-02

HUIZHOU ZEHONG TECH CO LTD

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the more mature one is ordinary sulfuric acid decorative anodizing. The membrane pores formed by ordinary sulfuric acid decorative anodizing are honeycomb, and the hardness is far inferior to that of ceramic anodizing. Moreover, there is no ceramic anodizing solution and ceramic anodizing on the market. Related news about the craft

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

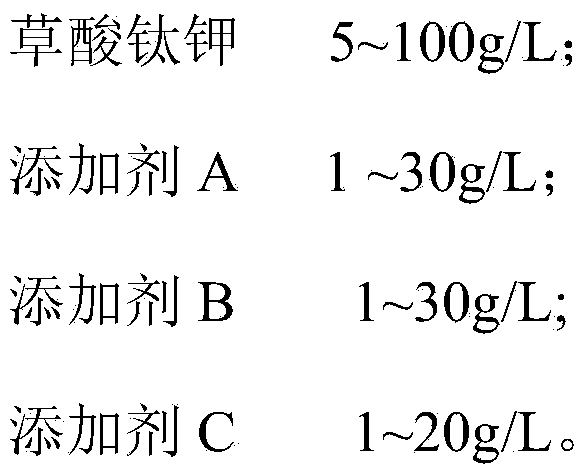

Login to View More Abstract

The invention relates to the technical field of anode oxidation solution formulas and anode oxidation processes, in particular to a ceramic anode oxidation solution and a ceramic anode oxidation process. The ceramic anode oxidation solution per liter comprises, by mass concentration, 5-100 g of titanium potassium oxalate, 1-30 g of additives A, 1-30 g of additives B and 1-20 g of additives C. The ceramic anode oxidation process comprises the steps that firstly, aluminum alloy materials to be subjected to ceramic anode oxidation are put in a reaction tank filled with the ceramic anode oxidation solution; and then the ceramic anode oxidation solution is heated to be at 15-60 DEG C, the voltage of 20-120 V is introduced, oxidation is conducted for 15-80 min, and the ceramic anode oxidation step is finished. The film thickness generated by a ceramic anode is in a tree root shape, the ceramic anode has incomparable hardness advantages compared with an ordinary anode, the surface color decoration range of an aluminum alloy ceramic oxidation film is enlarged, and the beautiful surface enamel sense is kept. Meanwhile, the ceramic anode has the firm and color appearance meeting different decorative requirements, and has good abrasion resistance, corrosion resistance and weather resistance properties in the use process, the process conditions are simple, and implementation is convenient.

Description

technical field The invention relates to the technical field of anodic oxidation liquid formula and anodic oxidation process, in particular to ceramic anodic oxidation liquid and ceramic anodic oxidation process. Background technique With the widespread use of aluminum alloy in the current 3C industry, as well as the advancement of science and technology and the improvement of people's living standards, the aesthetics have undergone significant changes, and its surface treatment technology has also developed rapidly. Among aluminum alloy surface treatment technologies, anodic oxidation technology is currently the most widely used and most successful. Anodizing is an electrolytic oxidation process in which the surface of aluminum alloys is usually converted into an oxide film. This oxide film has protective, decorative, and some other functional properties. Anodizing technology is a reliable metal surface treatment process. It guarantees consistent gloss and color of the m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D11/10C25D11/08

Inventor 江登山陈俊王亮

Owner HUIZHOU ZEHONG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com