Hydroxy acrylic resin aqueous dispersion and water-based coating prepared therefrom

A technology of hydroxyacrylic acid and dispersion, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as insufficient gloss, low solid content in coating construction, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

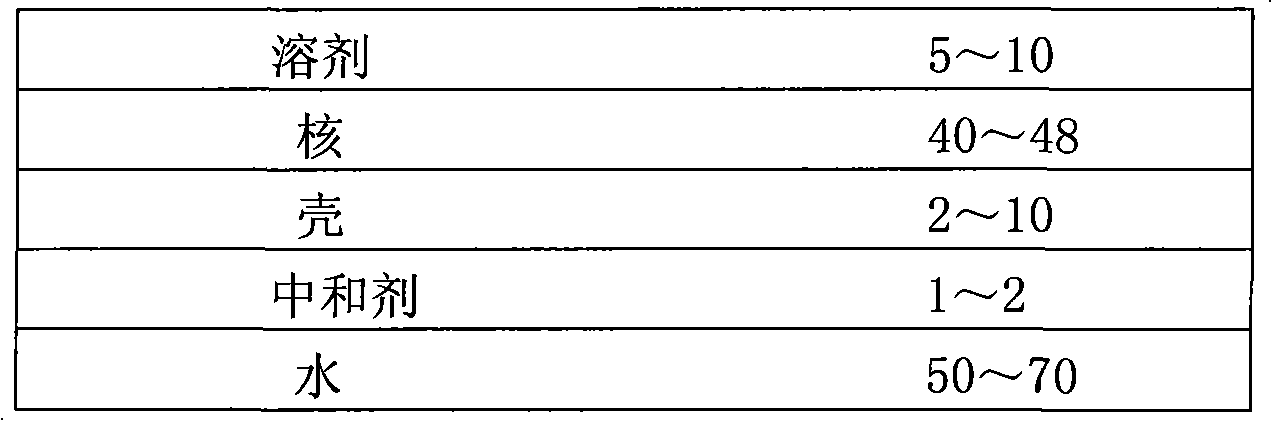

Method used

Image

Examples

example 1

[0034] This example is intended to demonstrate the preparation of aqueous dispersions of hydroxyacrylic resins, as follows:

[0035] (1) Add 100g propylene glycol butyl ether into the reaction vessel and stir to heat up to 150-160°C; add 100g styrene, 150g methyl methacrylate, 30g butyl acrylate, 90g hydroxyethyl acrylate, 30g dodecyl acrylate , 4g of n-dodecyl mercaptan and 12g of di-tert-butyl peroxide are mixed and dissolved to make a monomer drop feed, and the monomer drop feed is added to the reactor after the temperature of the reaction vessel rises to 150-160°C. Keep the reaction temperature at 150-160°C, and add the monomer dropwise for 4 hours. After the monomer is added dropwise, keep warm at 150-160°C for 1 hour. The weight solid content of the obtained resin solution is 80%, does not contain carboxyl group, and the number average molecular weight of the resin is 4000-5000.

[0036] (2) The temperature of the polymerization product in the first step is kept at 140...

example 2

[0040] This example shows aqueous dispersions of hydroxyacrylic resins prepared using different initiators, as follows:

[0041] (1) Add 100g ethylene glycol butyl ether into the reaction vessel and stir to heat up to 155-165°C; add 100g styrene, 200g methyl methacrylate, 216g butyl acrylate, 224g hydroxypropyl methacrylate, 60g coconut acrylic acid Oleate, 8g of n-dodecyl mercaptan, and 24g of di-tert-amyl peroxide are mixed and dissolved to make a monomer drop feed, and the monomer drop feed is added dropwise to the reactor after the temperature of the reaction vessel rises to 155-165°C. Keep the reaction temperature at 155-165° C., and add the monomer dropwise for 4 hours. After the monomer is added dropwise, keep warm at 155-165°C for 1 hour. The obtained resin solution had a solid content of 89% by weight. It does not contain carboxyl groups, and the number average molecular weight of the resin is 3500-4500.

[0042] (2) The temperature of the polymerization product in...

example 3

[0046] This example is intended to demonstrate the preparation of aqueous dispersions of hydroxylated acrylic resins with varying hydroxyl content

[0047] (1) Add 140g propylene glycol butyl ether into the reaction vessel and stir to heat up to 155-165°C; add 200g styrene, 300g methyl methacrylate, 100g butyl acrylate, 140g hydroxyethyl methacrylate, 60g dodecyl acrylate base ester, 8g of n-dodecyl mercaptan, and 24g of di-tert-amyl peroxide are mixed and dissolved to make a monomer drop feed, and the monomer drop feed is added to the reactor after the temperature of the reaction vessel rises to 155-165°C. Keep the reaction temperature at 155-165° C., and add the monomer dropwise for 4 hours. After the monomer is added dropwise, keep warm at 155-165°C for 1 hour. The obtained resin solution has a solid content of 85% by weight.

[0048] (2) The temperature of the polymerization product in the first step is kept at 155-165°C. Mix 30g methyl methacrylate, 15g butyl acrylate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com