Electrochemical battery and preparation method thereof

An electrochemical and battery technology, applied in the field of electrochemical batteries, can solve problems such as packaging failure, and achieve the effects of ensuring the packaging effect, better resistance to falling, and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

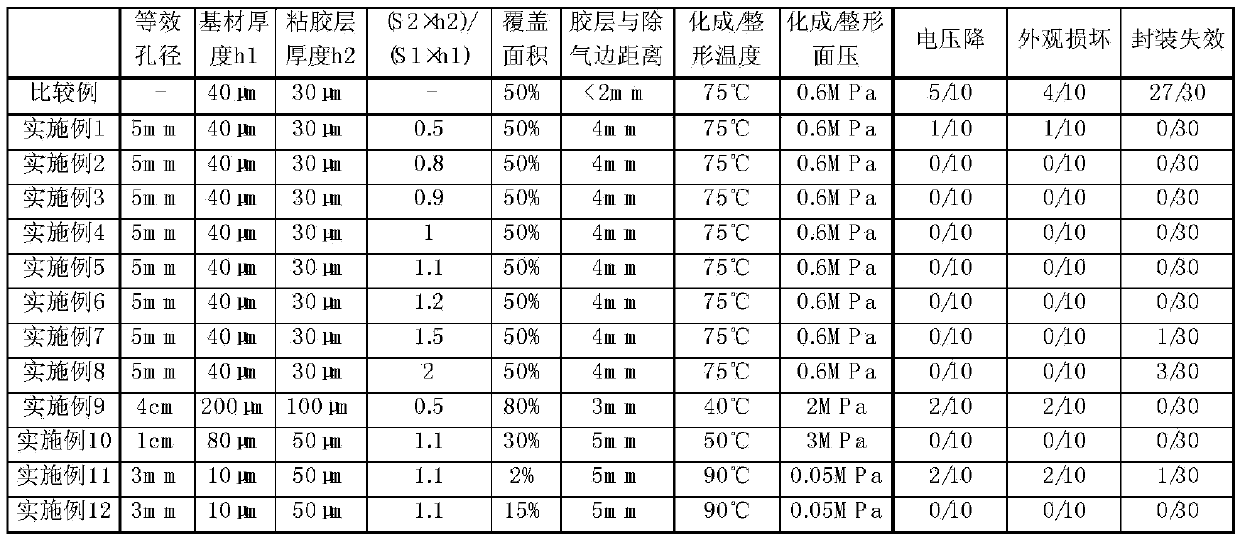

Examples

Embodiment 1

[0029] Embodiment 1, different from the comparative example, the present embodiment comprises the following steps:

[0030] Adhesive layer setting: choose a biaxially oriented polypropylene film with a thickness of 40 μm as the base material, and a polyurethane tape with a thickness of 30 μm as the adhesive layer, and then punch holes on the tape. The hole shape is circular and the hole spacing is equal. The diameter of the hole is 5mm, (S2×h2) / (S1×h1)=0.5, and the porous tape is obtained for use; the porous tape is pasted on the surface of the above-mentioned bare cell, and the tape (including the hole area) covers 50% of the surface area of the bare cell 50%, the distance between the tape and the side of the battery degassing package is 4mm; then put the bare cell in the outer packaging bag for top sealing and side sealing;

[0031] The rest are the same as those of the comparative example, and will not be repeated here.

Embodiment 2

[0032] Embodiment 2, different from Embodiment 1, this embodiment includes the following steps:

[0033]Adhesive layer setting: choose a biaxially oriented polypropylene film with a thickness of 40 μm as the base material, and a polyurethane tape with a thickness of 30 μm as the adhesive layer, and then punch holes on the tape. The hole shape is circular and the hole spacing is equal. The diameter of the hole is 5mm, (S2×h2) / (S1×h1)=0.8, and the porous tape is obtained for use; the porous tape is pasted on the surface of the above-mentioned bare cell, and the tape (including the hole area) covers 50% of the surface area of the bare cell 50%, the distance between the tape and the side of the battery degassing package is 4mm; then put the bare cell in the outer packaging bag for top sealing and side sealing;

[0034] The rest are the same as in Embodiment 1 and will not be repeated here.

Embodiment 3

[0035] Embodiment 3, different from Embodiment 1, this embodiment includes the following steps:

[0036] Adhesive layer setting: choose a biaxially oriented polypropylene film with a thickness of 40 μm as the base material, and a polyurethane tape with a thickness of 30 μm as the adhesive layer, and then punch holes on the tape. The hole shape is circular and the hole spacing is equal. The diameter of the hole is 5mm, (S2×h2) / (S1×h1)=0.9, and the porous tape is obtained for use; the porous tape is pasted on the surface of the above-mentioned bare cell, and the tape (including the hole area) covers 50% of the surface area of the bare cell 50%, the distance between the tape and the side of the battery degassing package is 4mm; then put the bare cell in the outer packaging bag for top sealing and side sealing;

[0037] The rest are the same as in Embodiment 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com