Polypropylene compound free of flame treatment and preparation method thereof

A technology of flame treatment and polypropylene, which is applied in the field of flame-free treatment of polypropylene composites and its preparation, can solve the problems of high cost and long time, and achieve the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

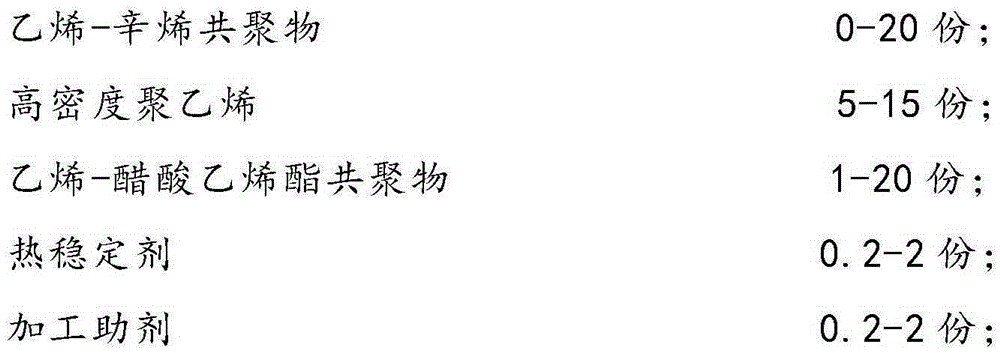

Method used

Image

Examples

Embodiment 1

[0039] 70kg polypropylene, 0.25kg phenolic heat stabilizer, 0.25kg phosphite heat stabilizer, 0.3kg processing aid, 10kg ethylene-vinyl acetate copolymer (vinyl acetate weight percent content is 40%), 12kg of ethylene-octene copolymer and 8kg of high-density polyethylene were dry-mixed in a high-speed mixer for 3-5 minutes at a mixing speed of 600 rpm at a temperature of 23°C, and then mixed raw materials at an aspect ratio of 40 :1 Melt and mix in the twin-screw extruder and then granulate to obtain the final product. The temperature of each section of the twin-screw extruder is set at 190-240°C.

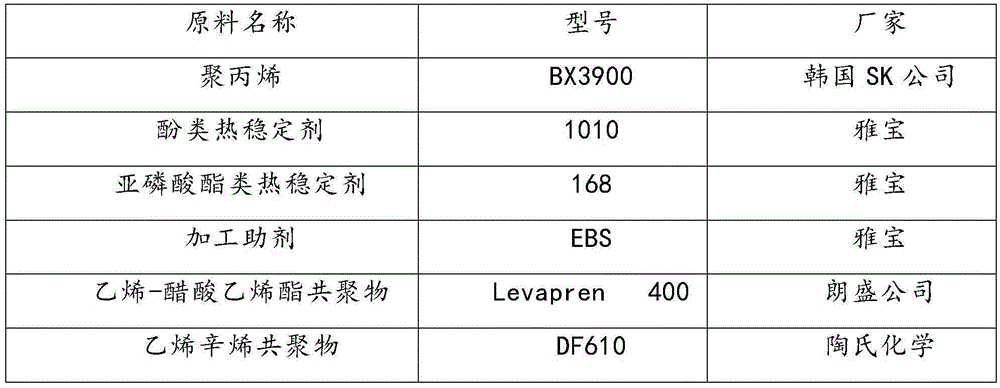

[0040] The models and manufacturers of the above raw materials are shown in the table below:

[0041]

[0042]

Embodiment 2

[0044] With 65kg polypropylene, 0.25kg phenolic heat stabilizer, 0.25kg phosphite heat stabilizer, 0.3kg processing aid, 12kg ethylene-vinyl acetate copolymer (vinyl acetate weight percent content is 34%), 15kg Ethylene octene copolymer and 8kg high-density polyethylene were dry mixed in a high-speed mixer for 3-5 minutes, the mixing speed was 600 rpm, and the mixing temperature was 23°C, and then the mixed raw materials were mixed at an aspect ratio of 40: 1. Melt and mix in the twin-screw extruder and then granulate to obtain the final product. The temperature of each section of the twin-screw extruder is set at 190-240°C.

[0045] The models and manufacturers of the above raw materials are shown in the table below:

[0046]

Embodiment 3

[0048] 65kg polypropylene, 0.25kg phenolic heat stabilizer, 0.25kg phosphite heat stabilizer, 0.3kg processing aid, 12kg ethylene-vinyl acetate copolymer (vinyl acetate weight percent content is 45%), 15kg Ethylene octene copolymer and 8kg high-density polyethylene were dry mixed in a high-speed mixer for 3-5 minutes, the mixing speed was 600 rpm, and the mixing temperature was 23°C, and then the mixed raw materials were mixed at an aspect ratio of 40: 1. Melt and mix in the twin-screw extruder and then granulate to obtain the final product. The temperature of each section of the twin-screw extruder is set at 190-240°C.

[0049] The models and manufacturers of the above raw materials are shown in the table below:

[0050]

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com