A kind of preparation method of high oil absorption hemp cellulose

A technology of hemp cellulose and hemp fiber, which is applied in the field of preparation of oil-absorbing materials, can solve problems such as difficult to achieve oil-absorbing effect, poor oil-absorbing effect, and low production of kapok, and achieve stable and easy-to-control process parameters, fast adsorption speed, and large oil-absorbing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] A preparation method of high oil-absorbing hemp cellulose, comprising the steps of:

[0060] (1) Preparation of treatment solution

[0061]Composition of treatment liquid (by weight, parts)

[0062]

[0063] Preparation method of treatment liquid:

[0064] ①. Weigh 56 parts of water, adjust the pH value to 3-4 with a buffer solution composed of citric acid and sodium citrate, add 10 parts of etherification agent, and hydrolyze it in a shaking water bath at 40°C for 2 hours until the surface of the solution is free. oil phase exists;

[0065] ②. Weigh 28 parts of water, add 4 parts of etherification agent and 2 parts of catalyst, stir to fully dissolve;

[0066] ③. Under stirring conditions, mix the etherification agent solution and the esterification agent solution evenly to form a treatment solution.

[0067] (2) Dipping treatment solution

[0068] The weight ratio of jute cellulose to the solution is 1-10, the fibrous cellulose is immersed in the treatment, an...

Embodiment 1-8

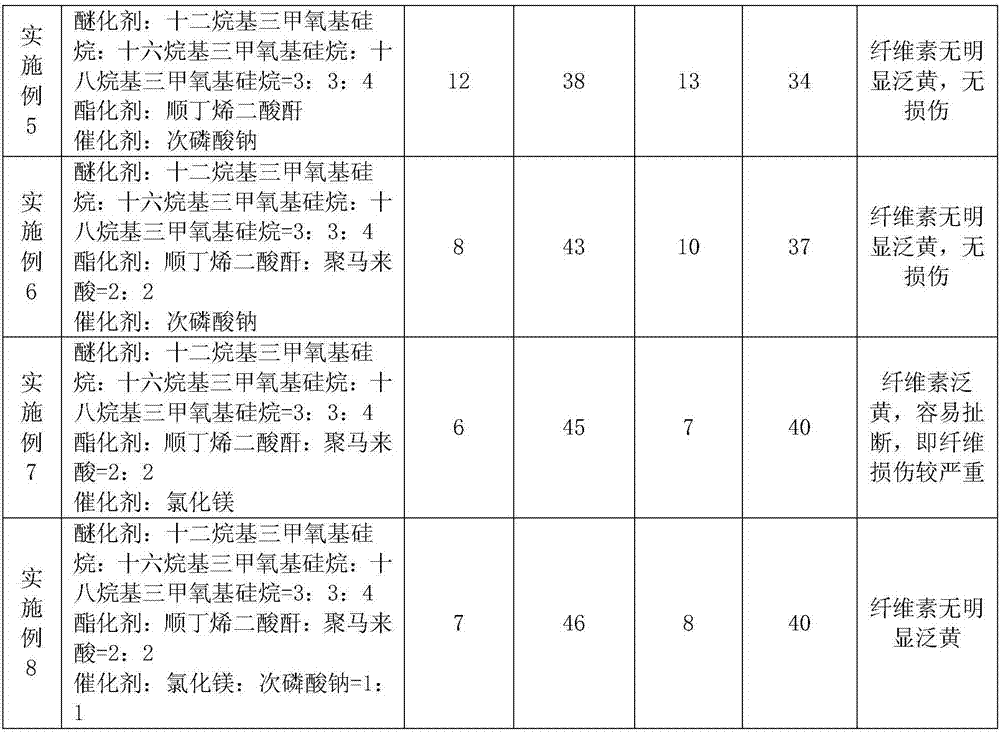

[0080] The basic process is the same as the first group of embodiments. The difference of each specific embodiment is that the composition and proportioning of the treatment liquid are adjusted, and the oil absorption effect of the product is detected and counted, as shown in Table 1:

[0081] Table 1: Effects of different treatment fluid compositions on product performance

[0082]

[0083]

[0084] It can be seen from Examples 1-4 that with the increase of the number of alkyl carbon atoms in the alkyltrimethoxysilane, the oil absorption rate and the oil absorption amount have a small increase, and the silane complex with low carbon number and high carbon number Compound modification has the best effect. This is because the more carbon atoms, the stronger the hydrophobicity of silane, and the greater the adsorption force to oil, but the more carbon atoms, the larger the silane molecule, and it is difficult for large molecules to enter the amorphous region with smaller p...

Embodiment 9-13

[0109] The basic process is the same as the second group of embodiments, the difference is that different drying processes are adjusted (note: the drying process here refers to the treatment process after dehydration, which is different from the drying process in step 7), and the oil absorption of the product is detected and counted The effect, as shown in Table 2:

[0110] Table 2. Effect of different drying processes on product performance.

[0111]

[0112] As shown in table 2:

[0113] Comparing Example 9 and Example 10, the use of pre-drying treatment can improve the oil absorption effect, this is because through pre-drying, the moisture is slowly volatilized from the inside of the cellulose at a lower temperature without the modifier Carried to the surface of cellulose to achieve the purpose of improving the modification effect.

[0114] It can be seen from Examples 10-12 that when the baking temperature is low (Example 11), the oil absorption effect is poor, probab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com