Antistatic heat-insulating aluminum film bag

An anti-static, aluminum film technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve problems such as time-consuming, affecting product function and life, troublesome, etc., to achieve strong adaptability to the environment, good Heat insulation effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

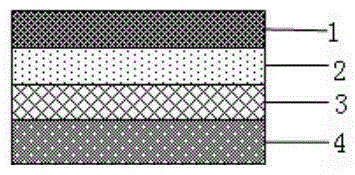

[0027] An antistatic and heat-insulating aluminum film bag in this embodiment includes a bag body, and the bag body sequentially includes a sun-proof fabric layer 1, a heat-dissipating and heat-insulating fabric layer 2, an aluminum film layer 3 and a support layer 4 from the outside to the inside, and the sunscreen fabric layer 1 is made of polyester fiber and mulberry silk fiber blended and woven, heat dissipation and heat insulation fabric layer 2 is made of blended and woven tencel fiber and flax fiber, aluminum film layer 3 is 5mm thick, and supporting layer 4 includes a metal layer and is wrapped in a metal layer The fabric on the surface is made of antistatic woven fabric, which is made of crossed monofilament spandex and antistatic silk. The fabric is composed of 2 layers of antistatic woven fabric, and the support layer 4 has a thickness of 650um.

Embodiment 2

[0029] Compared with Example 1, the present embodiment is that the sunscreen fabric layer 1 is replaced by blended weaving of spandex fiber, polyester fiber and mulberry silk fiber, and the others are the same.

Embodiment 3

[0031] Compared with Embodiment 1, this embodiment is replaced by blended weaving of vinylon fiber and ramie fiber for heat dissipation and heat insulation fabric layer 2, and the others are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com