Heavy-load grinding wheel and machining method thereof

A heavy-duty grinding wheel and grinding wheel technology, applied in the field of mechanical processing, can solve the problems of low yield, easy breakage, low grinding efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

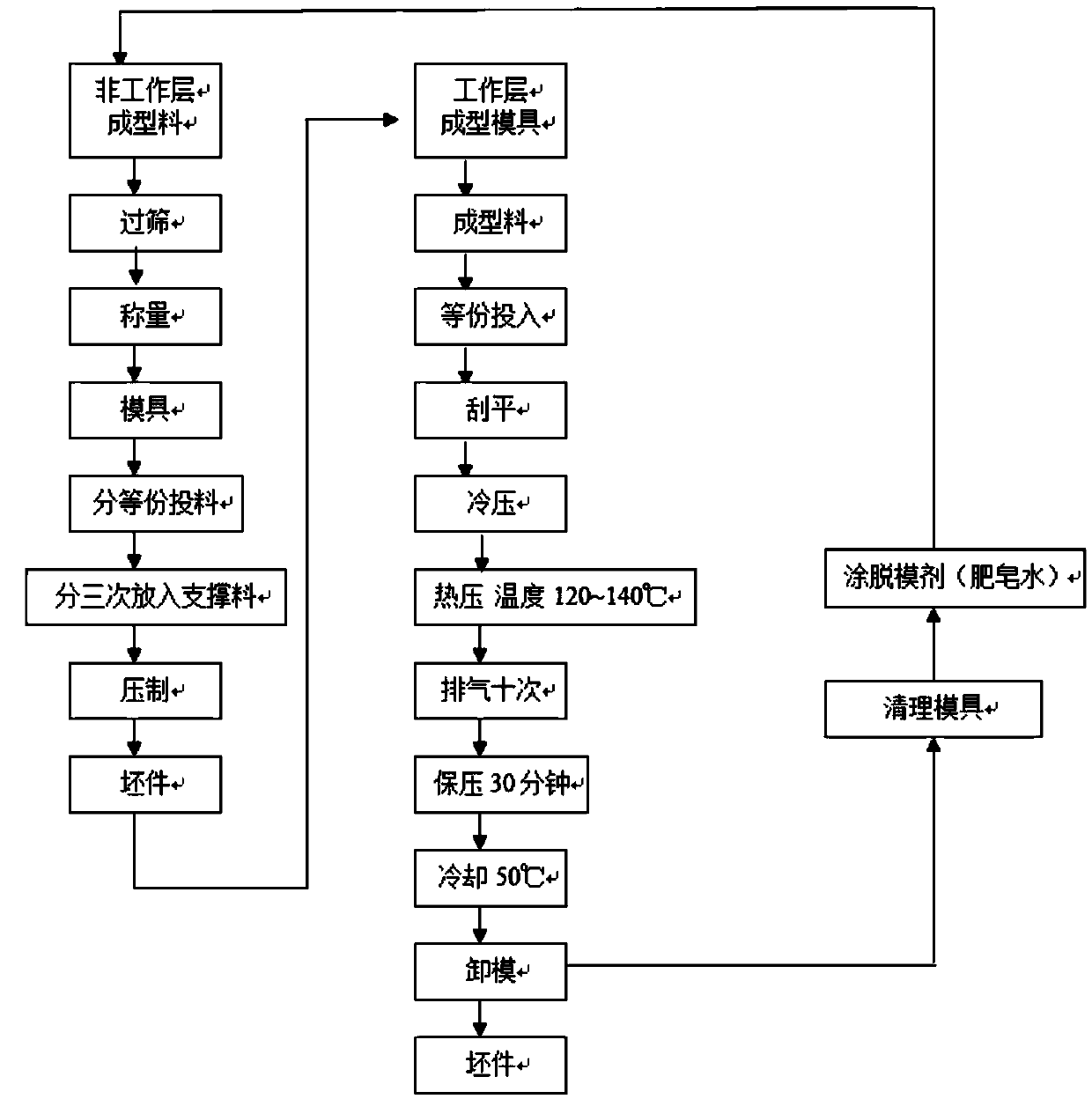

Method used

Image

Examples

Embodiment 1

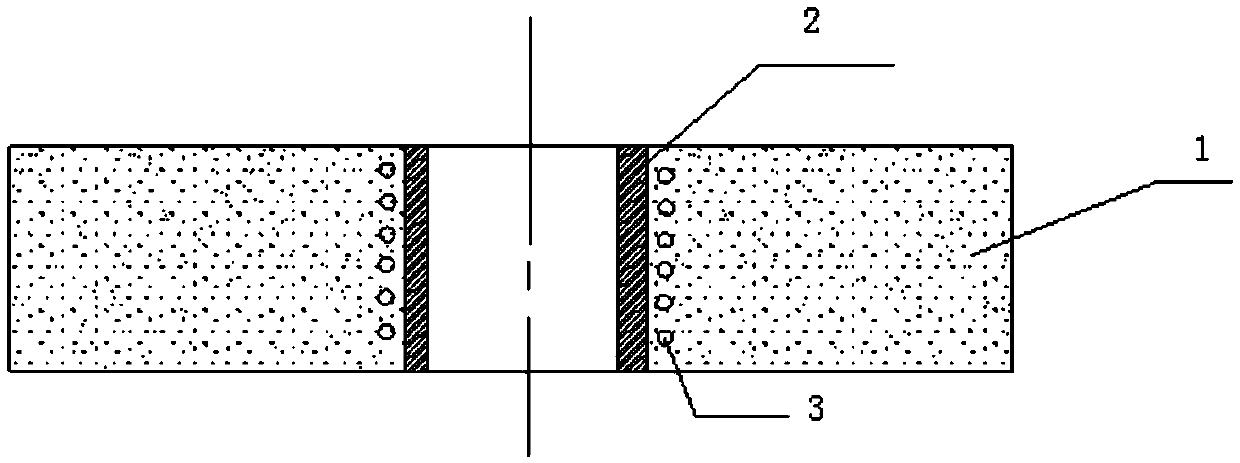

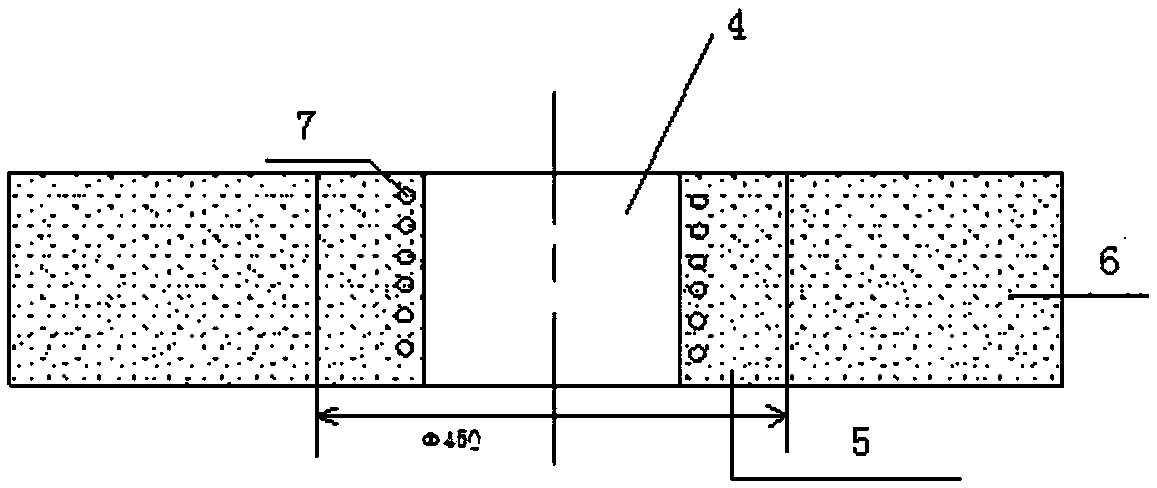

[0040] The heavy-duty grinding wheel described in this embodiment is divided into an inner layer part and an outer layer part prepared from different raw materials, wherein:

[0041] The inner part is prepared from the following components: C120# grain size sand 10kg, furfural 0.6L, butyral 0.2-0.5 parts by weight kg, alkali-free chopped glass fiber 3.5kg, new phenol resin 3kg, German resin PF06514kg 、KEP21kg;

[0042] The outer part is prepared from the following components: 8# zirconium corundum 50kg, 12# zirconium corundum 35kg, 14# zirconium corundum 20kg, 24# zirconium corundum 10kg, 80# zirconium corundum 1kg, alkali-free chopped glass fiber 9kg , New phenol resin 6jg, German resin PF065116kg, KEP23kg, PYROX12kg, cryolite 4kg, barite 4kg.

Embodiment 2

[0044] The heavy-duty grinding wheel described in this embodiment is divided into an inner layer part and an outer layer part prepared from different raw materials, wherein:

[0045] The inner part is prepared from the following components: C120# grain size sand 15kg, furfural 0.4L, butyral 0.5kg, alkali-free chopped glass fiber 2kg, new phenol resin 4kg, German resin PF06512kg, KEP22kg;

[0046] The outer part is prepared from the following components: 8# zirconium corundum 75kg, 12# zirconium corundum 20kg, 14# zirconium corundum 30kg, 24# zirconium corundum 6kg, 80# zirconium corundum 3kg, alkali-free chopped glass fiber 7kg , New phenol resin 9kg, German resin PF065112kg, KEP24kg, PYROX9kg, cryolite 6kg, barite 2kg.

Embodiment 3

[0048] The heavy-duty grinding wheel described in this embodiment is divided into an inner layer part and an outer layer part prepared from different raw materials, wherein:

[0049] The inner part is prepared from the following components: C120# grain size sand 11.3kg, furfural 0.5L, butyral 0.3kg, alkali-free chopped glass fiber 2.8kg, new phenol resin 3.3kg, German resin PF06513kg, KEP21 .5kg;

[0050] The outer part is prepared from the following components: 8# zirconium corundum 60kg, 12# zirconium corundum 28kg, 14# zirconium corundum 26kg, 24# zirconium corundum 8kg, 80# zirconium corundum 2kg, alkali-free chopped glass fiber 8.2 kg, new phenol resin 7.5kg, German resin PF065114.5kg, KEP23.2kg, PYROX10.6kg, cryolite 5kg, barite 3kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com