Ultrathin windable segment-code-type electronic ink screen and preparing method

An electronic ink screen, electronic ink technology, applied in the direction of identification devices, nonlinear optics, instruments, etc., can solve the problems of electronic ink screen display function failure, ITO square resistance difficult to drive, low light transmittance, etc., to achieve high yield rate , low cost, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

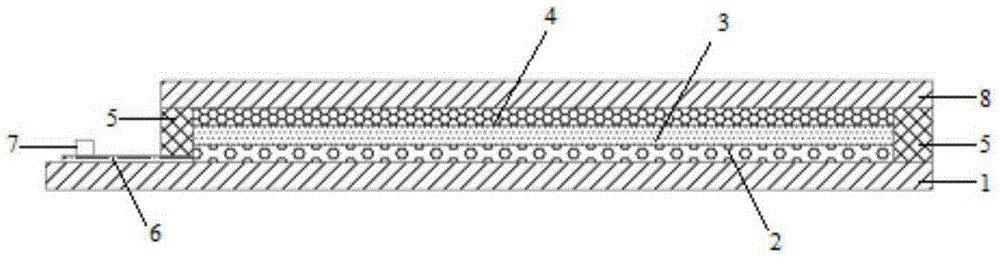

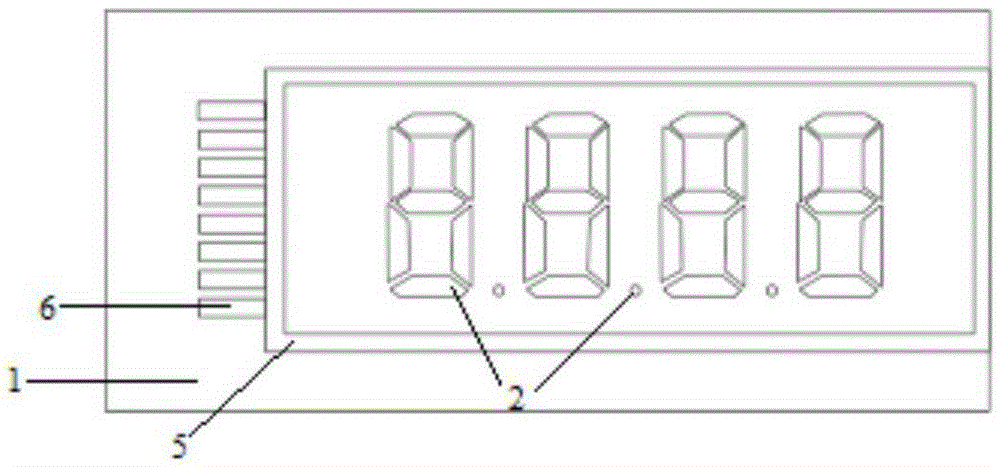

[0036] As shown in the figure, an ultra-thin and bendable segment code electronic ink screen provided by this embodiment includes a back electrode substrate 1, a back electrode conductive film 2, an electronic ink layer 3, a front electrode conductive film 4, and a frame glue 5. Metal leads 6, display driver IC 7 and front electrode substrate 8;

[0037] The back electrode conductive film is set on the back electrode base material; the front electrode conductive film is set on the front electrode base material; the electronic ink layer is set between the back electrode conductive film and the front electrode conductive film; the back electrode base material A frame glue is arranged between the base material of the front electrode; a display driver IC is arranged on one end of the back electrode substrate; the display driver IC is connected to the conductive film of the back electrode through metal leads.

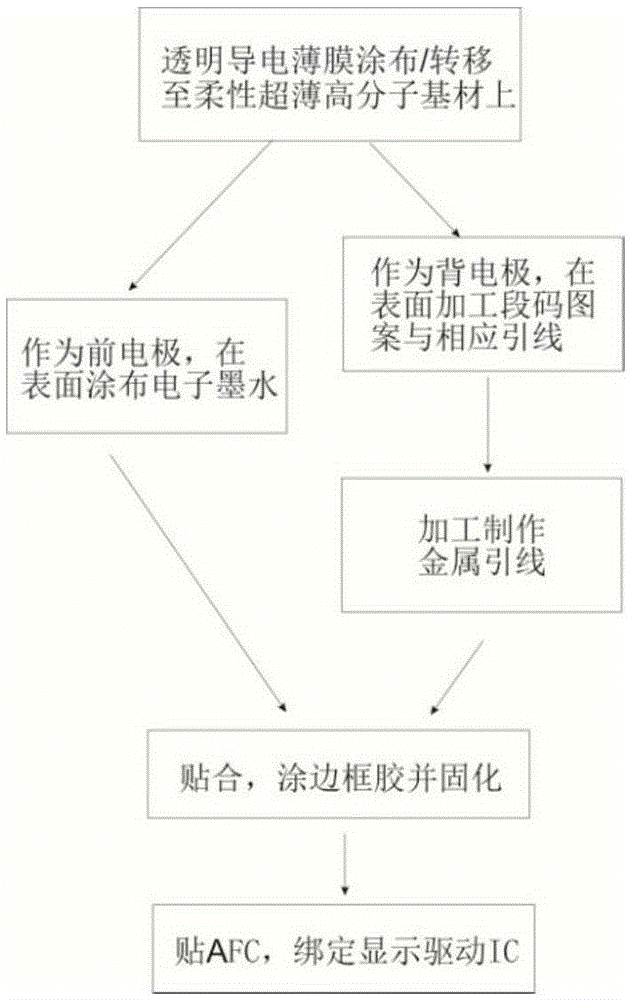

[0038] The back electrode substrate and the front electrode substrate a...

Embodiment 2

[0060] The ultra-thin bendable segment-coded electronic ink screen provided in this embodiment uses polymer materials (such as PI, PET, PEN, PC, PMMA, etc.) with thin thickness and excellent bending performance as the electrodes of the segment-coded electronic ink screen Substrate; at the same time, graphene or carbon nanotubes or silver nanowires with good bending performance are used instead of ITO as the electrode conductive material of the segment code electronic ink screen; and an ultra-thin bendable segment code is realized with a simple structure Type electronic ink screen, the manufacturing method is simple.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com