Direct-injection annular fire cover and cutting tool for a burner

A burner and annular cover technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of low thermal efficiency, insufficient mixing, temperature rise, etc., and achieve high production quality and improved thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

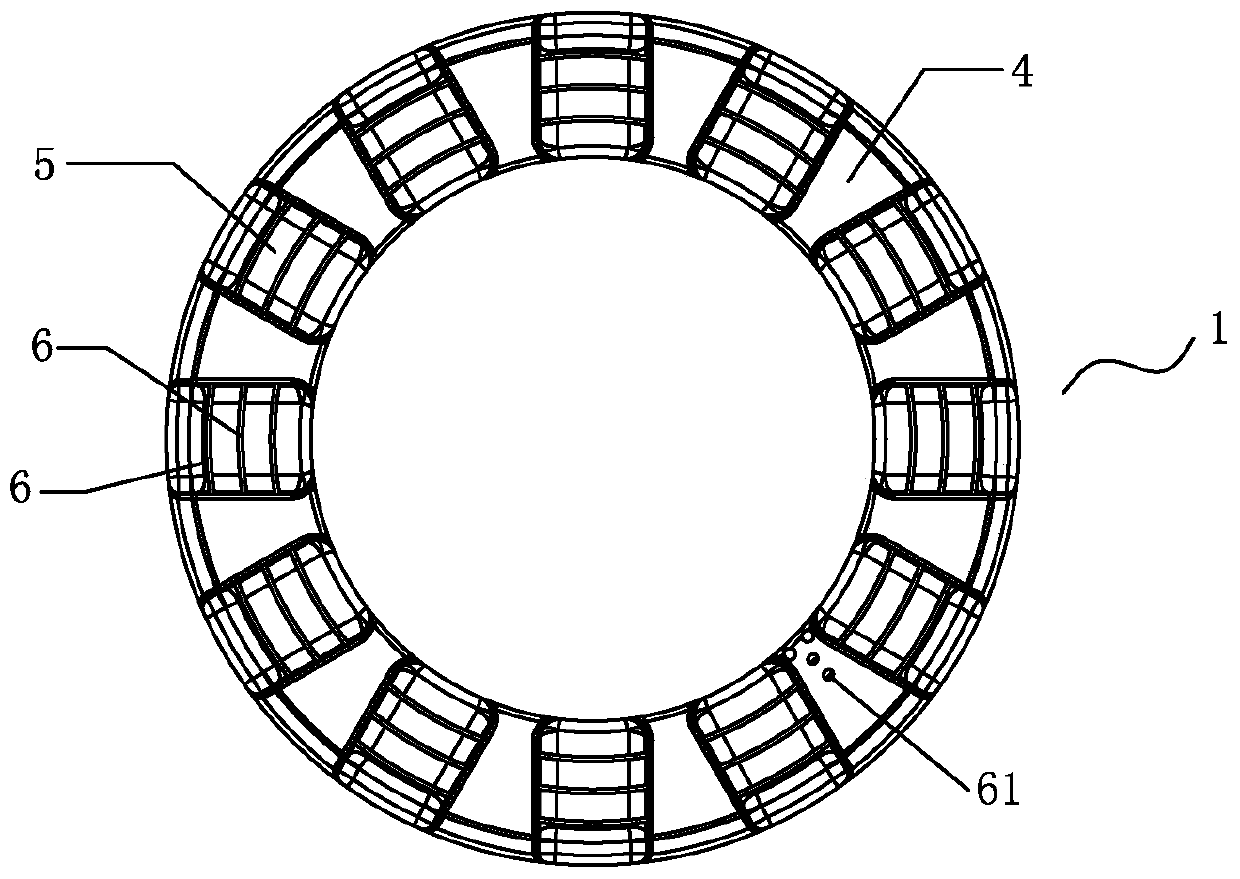

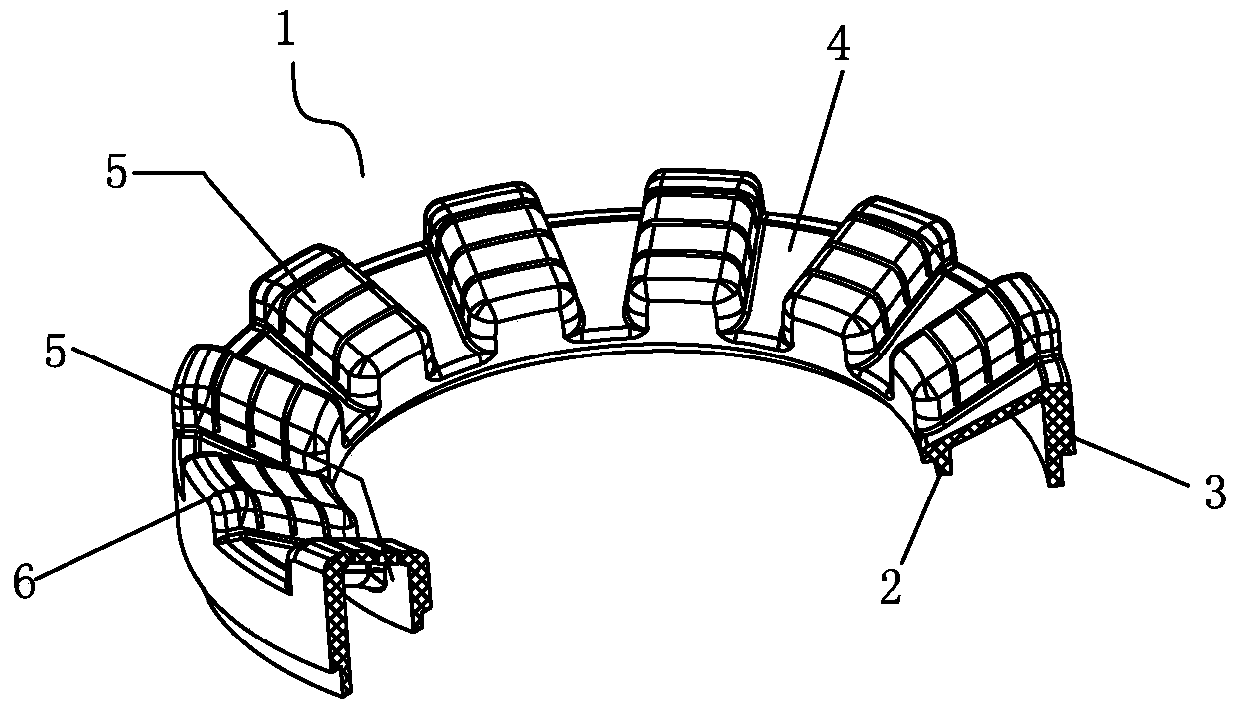

[0026] Such as figure 1 , figure 2 As shown, a direct-injection annular fire cover for a burner includes a fire cover body 1 , and the fire cover body 1 includes an inner ring wall plate 2 , an outer ring wall plate 3 and a circular top cover 4 . The annular cover plate 4 is in the shape of an inverted truncated cone, and there are several hollow premixing chambers 5 that open downward on the annular cover plate 4, and the length direction of the premixing chamber 5 is along the busbar direction of the annular cover plate 4 ;

[0027] There are combustion holes 6 on the premix chamber 5 .

[0028] The combustion holes 6 are arc-shaped, and several combustion holes are distributed on concentric circles with different diameters;

[0029] Adjacent combustion holes on two adjacent premix chambers 5 are on a circle.

[0030] The present invention can also be realized in the following way: the combustion hole 6 is in a spiral shape, there are several combustion holes on the pre...

Embodiment 2

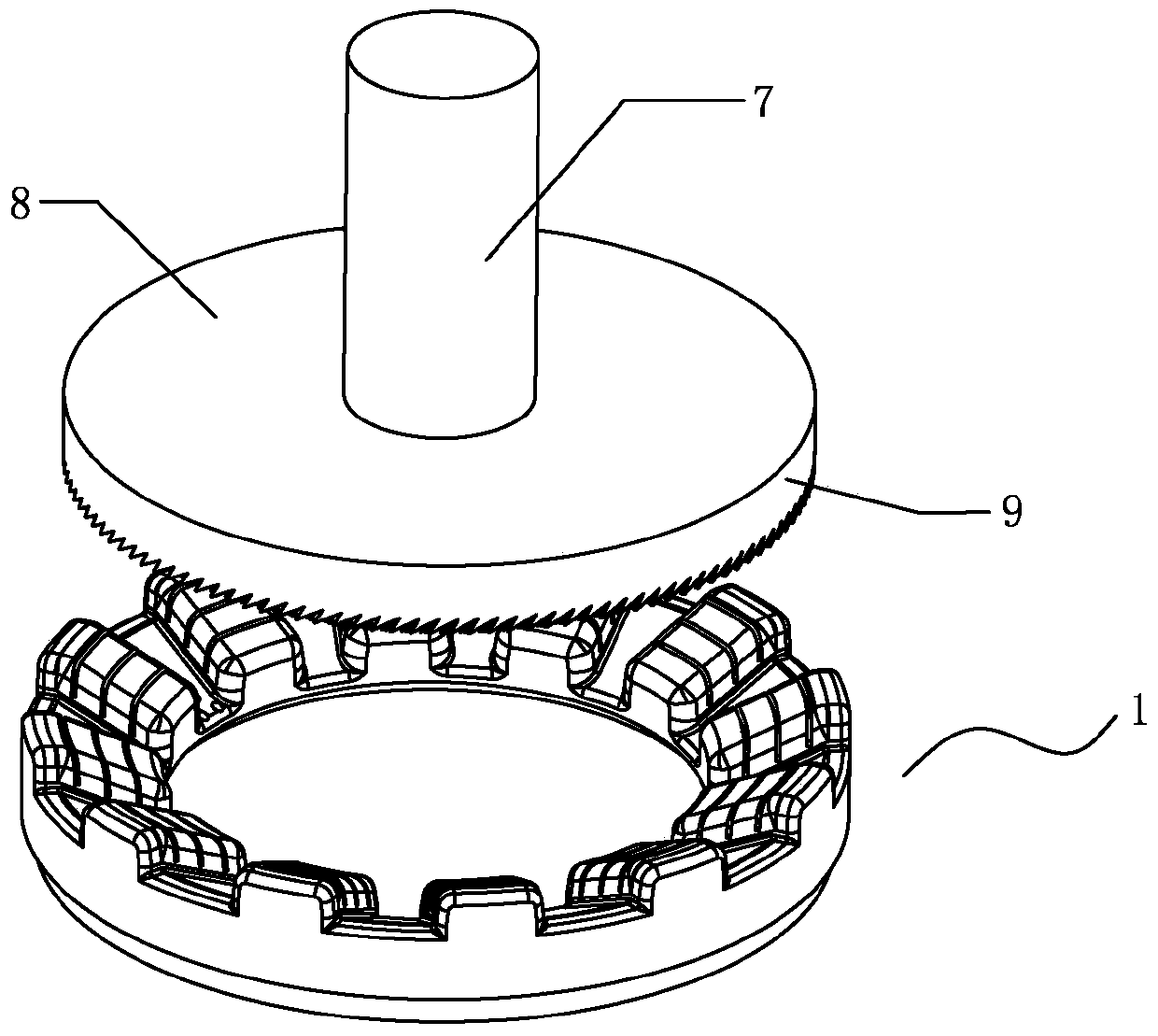

[0033] Such as image 3 , Figure 4 Shown, a kind of cutting tool, it comprises driving shaft 7, base 8 and at least two cutting knives 9;

[0034] The cutting knife 9 includes a cylindrical seat 91 and several cutter bodies 92 provided with the ends of the cylindrical seat;

[0035] One end of the drive shaft 7 is fixedly connected to the base 7, and the cylindrical seat 91 of the cutter is fixedly connected to the base 8;

[0036] The length of the cylindrical seat 91 decreases gradually from the radially inner side to the radially outer side of the base 8 of the cutting blade 9 .

[0037] During use, the fire cover body 1 moves along a straight line, and the drive shaft 7 drives the cutting knife 9 to rotate, and the process can be completed.

Embodiment 3

[0039] Such as Figure 5 , Figure 6 Shown, a kind of cutter, it comprises base 8 and at least two cutting blades 9; Cutting blade 9 is circular arc; Cutting blade 9 is arranged on one end of base 8, and the other end of base 8 is a fixed end;

[0040] The cutting knives 9 are distributed in the form of concentric circles of different diameters;

[0041] The cutting blade 9 takes the fixed end of the base 8 as the center of a circle, and the height from the cutting edge to the base 8 gradually decreases from the radially inner side to the radially outer side.

[0042] When the present invention is in use, as Figure 6 As shown, the fire cover body 1 rotates, and the cutter moves forward along a straight line, which can be completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com