Ammonia gas generating device for diesel vehicle filter

A technology of ammonia gas generation and filter, which is applied in the direction of exhaust device, muffler device, machine/engine, etc. It can solve the problems of easy clogging, poor mixing effect of direct injection generator, etc., and achieve reasonable design and optimized exhaust The effect of pipe layout and high denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

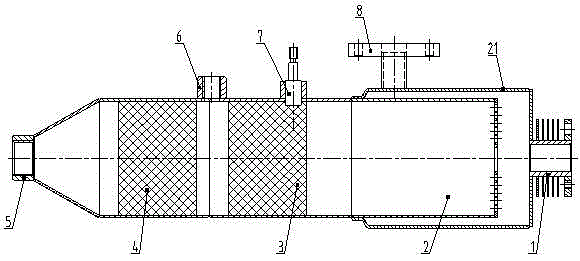

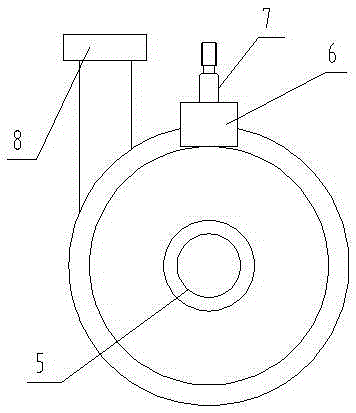

[0014] Such as figure 1 As shown, the present invention provides an ammonia generating device for a diesel vehicle filter, comprising a urea inlet 1, a urea heating chamber 2, an electric heating catalyst 3, a hydrolysis catalyst 4, an ammonia nozzle 5, a temperature sensor joint 6, an electric heating Connector 7, automobile exhaust inlet 8, the ammonia gas generating device is cylindrical as a whole, one end of the housing is provided with an ammonia gas nozzle 5, the other end is provided with a urea heating chamber 2, and the outside of the urea heating chamber 2 is provided with a sleeve 21, A cavity is provided between the sleeve 21 and the housing, and the cavity communicates with the urea heating chamber 2 at the end face of the housing. A urea inlet 1 located on the same axis as the ammonia nozzle 5 is provided on the outside of the sleeve 21. The urea inlet 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com