Light free-spraying nylon material and preparation method thereof

A spray-free, nylon technology, applied in the field of polymer materials, can solve the problems of waste of resources, increased processing costs of plastic parts, and yield problems, etc., to reduce the weight of parts, improve tensile strength, and high product yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

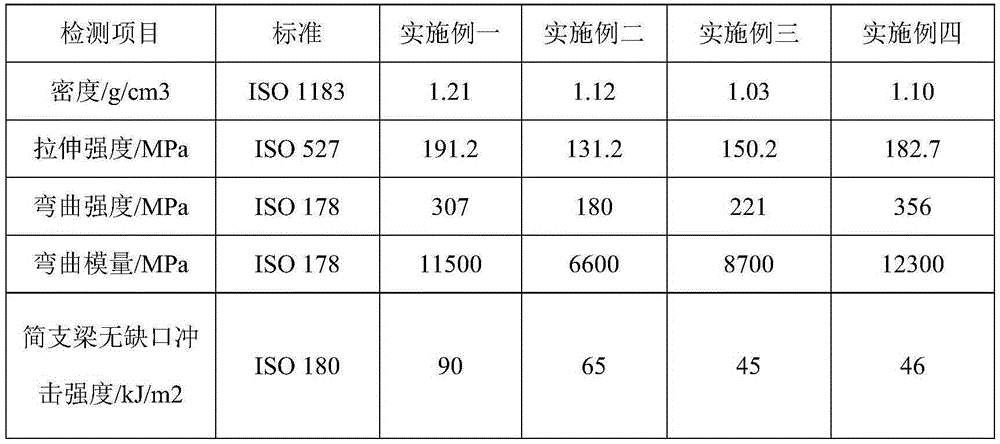

Examples

Embodiment 1

[0032] Put 6650 parts of nylon, 5 parts of maleic anhydride grafted polyolefin elastomer, 10980.6 parts of antioxidant, 1680.4 parts of antioxidant, 2 parts of silicone, and 1 part of aluminum powder masterbatch into a high-speed mixer, and mix for 6 minutes. Then, the above-mentioned component mixture is continuously fed into the twin-screw extruder from the hopper, and 40 parts of glass fibers are fed into the barrel of the twin-screw extruder from the feeding port in the middle of the extruder in a side-feeding manner for mixing. Cool, dry, and pelletize to obtain a reinforced nylon composite material with metallic luster. The temperature range of each section of twin-screw extruder barrel from feeding port to machine head is: Zone I: 230°C, Zone II: 250°C, Zone III: 250°C, Zone IV: 250°C, Zone V: 250°C, Zone VI Zone: 250°C, Zone VII: 250°C, Zone VIII: 240°C, Zone IX 240°C, screw speed 600r / min; 99 parts of the obtained carbon fiber reinforced nylon composite material and 1...

Embodiment 2

[0034] Put 6668.5 parts of nylon, 1 part of maleic anhydride grafted polyethylene, 10980.12 parts of antioxidant, 1680.08 parts of antioxidant, 0.3 part of polytetrafluoroethylene, and 5 parts of zinc powder masterbatch into a high-speed mixer, and mix for 3 minutes. Then, the above-mentioned component mixture is continuously fed into the twin-screw extruder from the hopper, and 20 parts of glass fibers are fed into the barrel of the twin-screw extruder from the feeding port in the middle of the extruder in a side-feeding manner for mixing. Cool, dry, and pelletize to obtain a reinforced nylon composite material with metallic luster. The temperature range of each section of the twin-screw extruder barrel from the feed port to the head is: Zone I: 235°C, Zone II: 255°C, Zone III: 255°C, Zone IV: 260°C, Zone V: 260°C, Zone VI Zone: 260°C, Zone VII: 255°C, Zone VIII: 245°C, Zone IX 245°C, screw speed 600r / min; put 95 parts of the obtained glass fiber reinforced nylon composite ma...

Embodiment 3

[0036] Put 6670 parts of nylon, 3 parts of maleic anhydride grafted polyolefin elastomer, 10980.6 parts of antioxidant, 1680.4 parts of antioxidant, 1 part of calcium stearate, and 3 parts of copper zinc powder masterbatch into a high-speed mixer, mix 4 minutes, then, the above-mentioned component mixture was continuously added into the twin-screw extruder from the hopper, and 20 parts of carbon fibers were added into the barrel of the twin-screw extruder through the feeding port in the middle of the extruder in a side-feeding manner for mixing. strips, cooled, dried, and pelletized to obtain a reinforced nylon composite material with a spraying effect. The temperature range of each section of the twin-screw extruder barrel from the feed port to the head is: Zone I: 240°C, Zone II: 270°C, Zone III: 265°C, Zone IV: 270°C, Zone V: 270°C, VI Zone: 270°C, Zone VII: 270°C, Zone VIII: 260°C, Zone IX: 260°C, screw speed 600r / min; put 98 parts of the obtained carbon fiber reinforced n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com