Machining method of horn-shaped seal head

A processing method and a horn-shaped technology, applied in the processing field of the horn-shaped head, can solve the problems of high scrap rate, reduced production efficiency, prolonged delivery period, etc., and achieve good shape consistency, improved production efficiency, and shortened delivery time. effect of deadlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

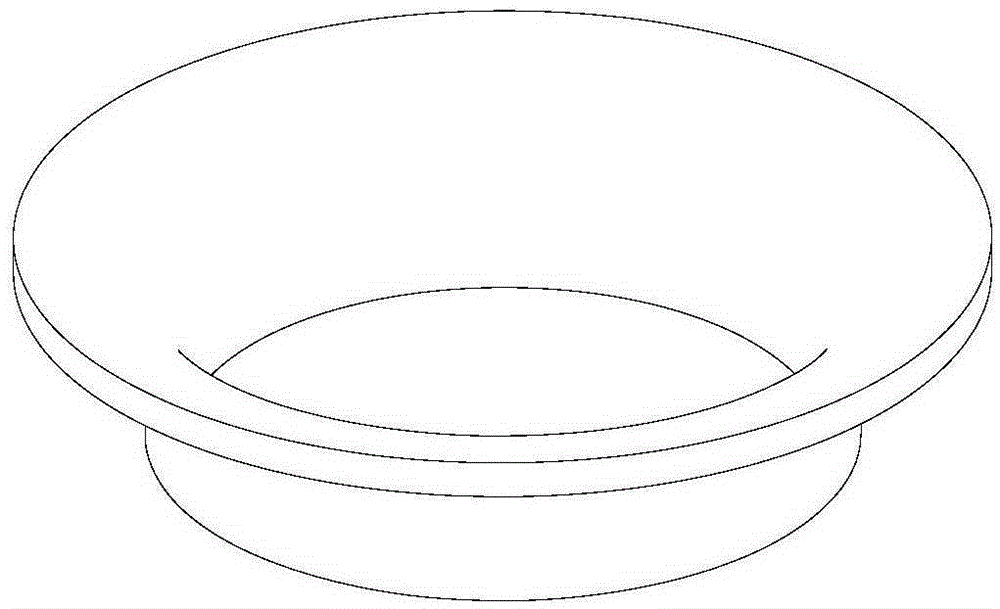

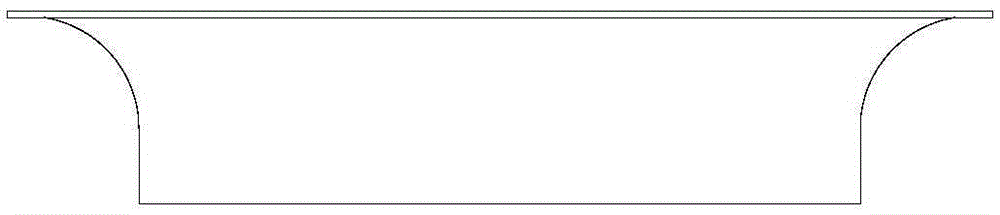

[0024] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

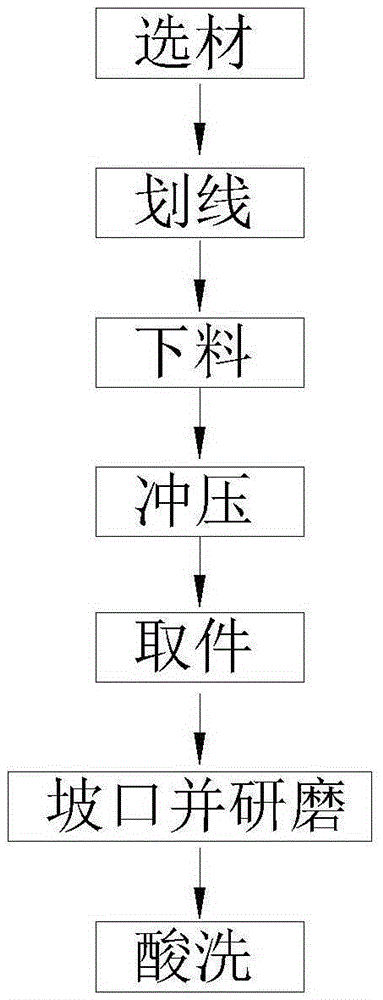

[0025] refer to Figure 1-4 Shown, the processing method of a kind of trumpet-shaped end of the present invention comprises the following steps,

[0026] Step one, material selection;

[0027] Step 2: draw a line, draw a group of concentric circles on the plate according to the size requirements of the design, as the basis for the blanking size, in this embodiment, the diameters of the two concentric circles are 350mm and 492mm respectively;

[0028] Step 3: blanking, cutting the plate to form a circular ring piece, specifically, cutting by means of plasma cutting;

[0029] Step 4: stamping, cold stamping the circular ring piece through the punching machine and the stamping d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com