Preparation method of nano iron phosphate with globulomer structure for lithium iron phosphate

A lithium iron phosphate, nano-scale technology, which is applied in the field of preparation of nano-scale iron phosphate, can solve the problems of low ion transmission rate, low electronic conductivity, and difficult nano-materials of lithium iron phosphate, so as to achieve high reactivity and vibration The effect of high density and particle size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

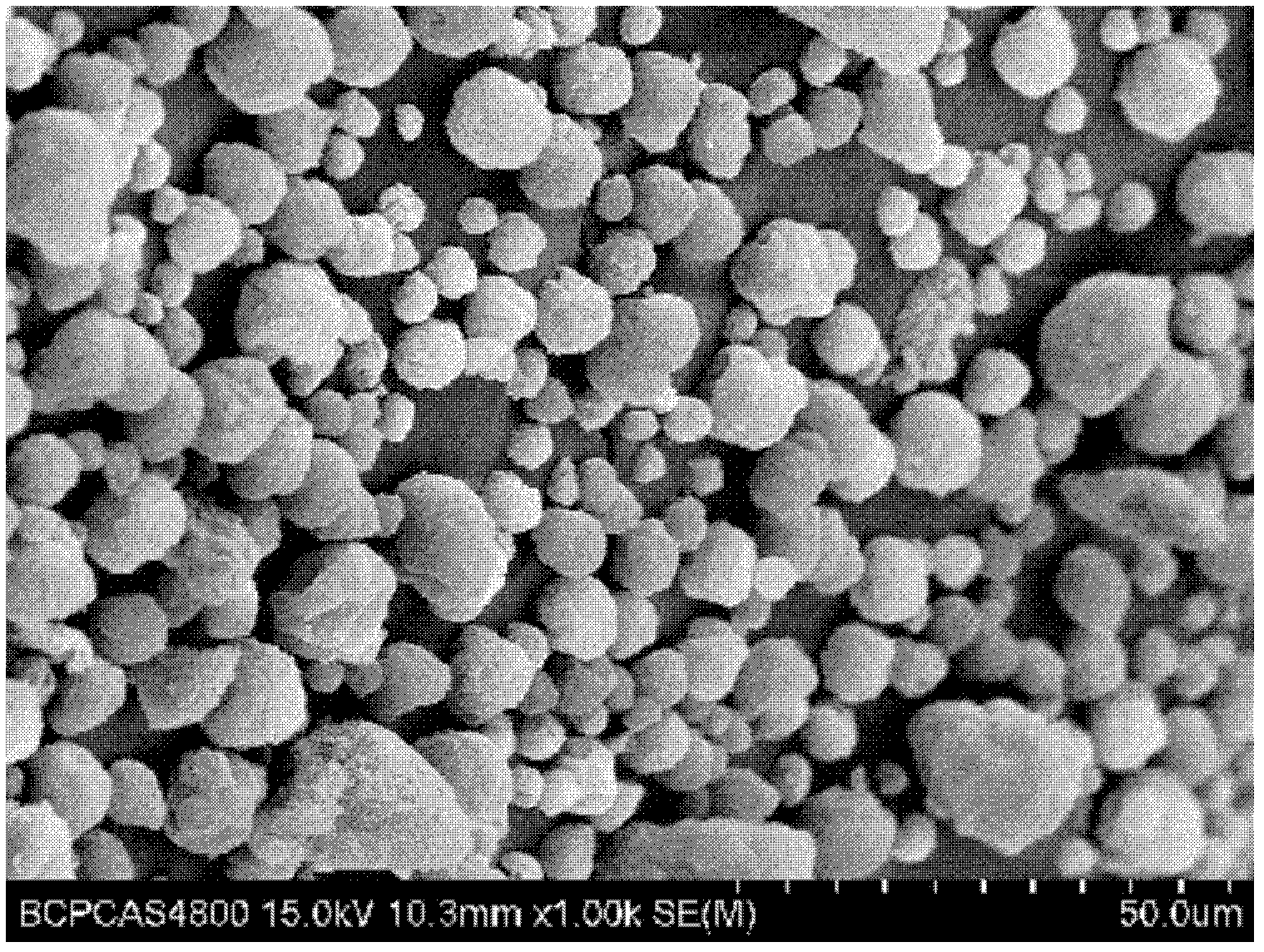

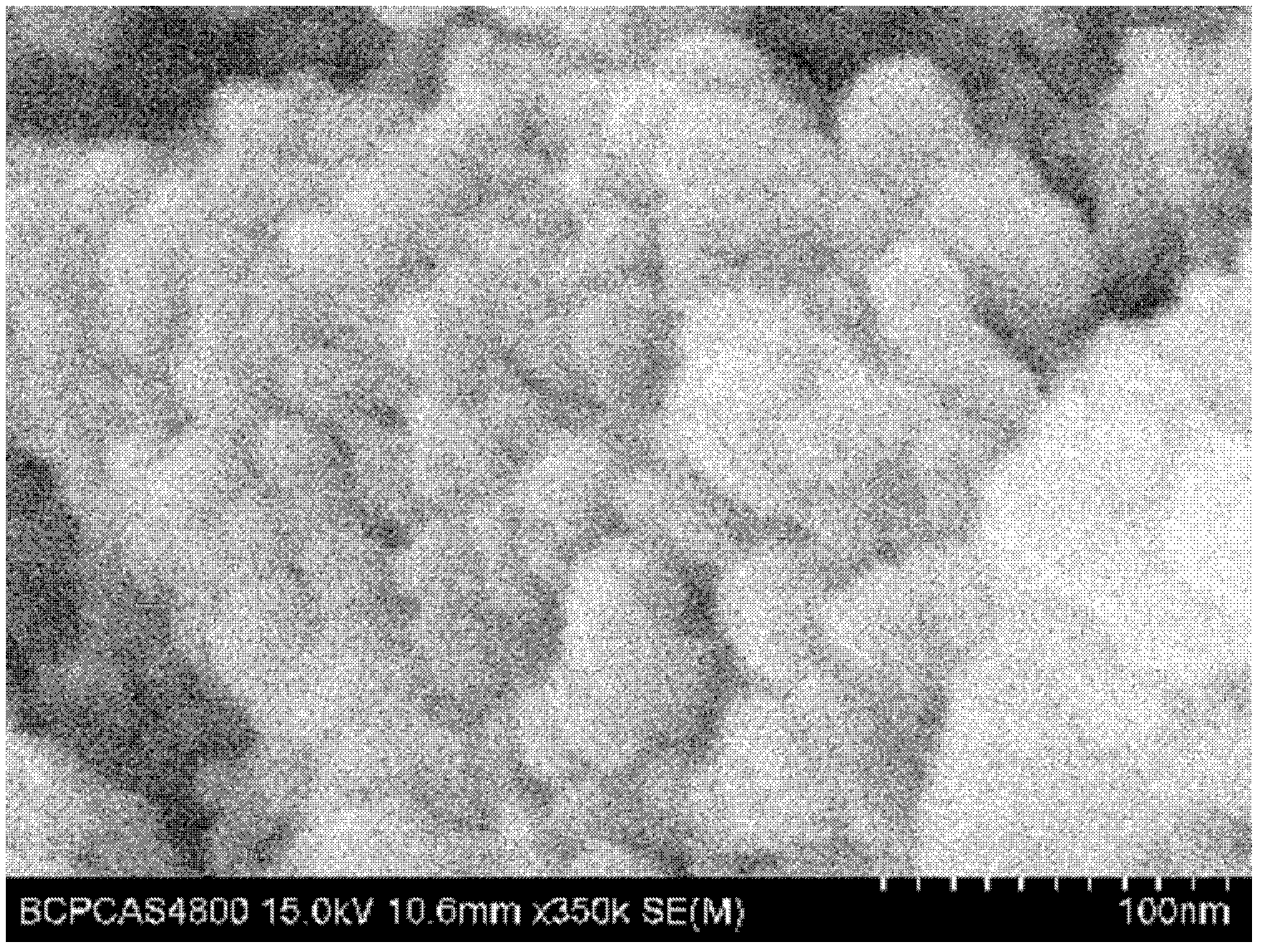

[0022] with Fe 2 (SO 4 ) 3 、H 3 PO 4 as the raw material, where PO 4 3- and Fe 3+ The mass ratio of the substances is 1:1. Dissolve the above reagents in deionized water to obtain a transparent homogeneous solution. After mixing the above solutions evenly, add ammonia solution, adjust the pH to 8, and heat the above mixed liquid in a water bath at 80°C for 1 hour until the active ingredients are fully precipitated. The flocculent suspension is filtered to obtain a white filter cake, and the filter cake is washed with deionized water. The difference in the conductivity value of the two consecutive washes is within 5% before the washing is completed; the liquid phase controlled crystallization process is used to prepare primary particles. Secondary granulation is carried out through the spray drying process. After spray drying, the primary particles with a particle size of 30nm are agglomerated to form spherical aggregates with a particle size of 5-20μm and micron-sized g...

Embodiment 2

[0025] With Fe(NO 3 ) 3 、H 3 PO 4 as the raw material, where PO 4 3- and Fe 3+ The molar ratio of the substances is 1:1.1. Dissolve the above reagents in deionized water to obtain a transparent homogeneous solution. After mixing the above solutions evenly, add ammonia solution, adjust the pH to 7, and then heat the above mixed liquid in a water bath at 60°C for 2 hours until the active ingredients are fully precipitated and form flocs. After filtering, a white filter cake was obtained, and the filter cake was washed with deionized water. The difference between the conductivity values of the two consecutive washes was within 5% and then the washing was completed; the liquid-phase controlled crystallization process was used to prepare the primary particle, and then The secondary granulation is carried out through the spray drying process. After spray drying, the primary particles with a particle size of 30nm are agglomerated to form a spherical aggregate with a particle ...

Embodiment 3

[0027] with FeCl 3 、H 3 PO 4 as the raw material, where PO 4 3- and Fe 3+ The mass ratio of the substances is 1:1.2. Dissolve the above reagents in deionized water to obtain a transparent homogeneous solution, mix the above solutions evenly, add ammonia solution, adjust the pH to 8.5, and heat the above mixed liquid in a water bath at 100°C for 1.5 hours until the active ingredients are fully precipitated and form flocs After filtering, a white filter cake was obtained, and the filter cake was washed with deionized water. The difference between the conductivity values of the two consecutive washes was within 5% and then the washing was completed; the liquid-phase controlled crystallization process was used to prepare the primary particle, and then The secondary granulation is carried out through the spray drying process. After spray drying, the primary particles with a particle size of 30nm are agglomerated to form a spherical aggregate with a particle size of 5-20μm an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com