Microwave preparation method of lanthanum-cerium-terbium oxide fluorescent powder

A technology of terbium oxide and fluorescent powder, which is applied in the field of preparation of rare earth oxides. It can solve the problems of difficulty in obtaining products with uniform composition, poor crystal growth particle size, and difficulty in controlling the shape, so as to achieve easier control of shape growth and lower surface charge. Good consistency of sex and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

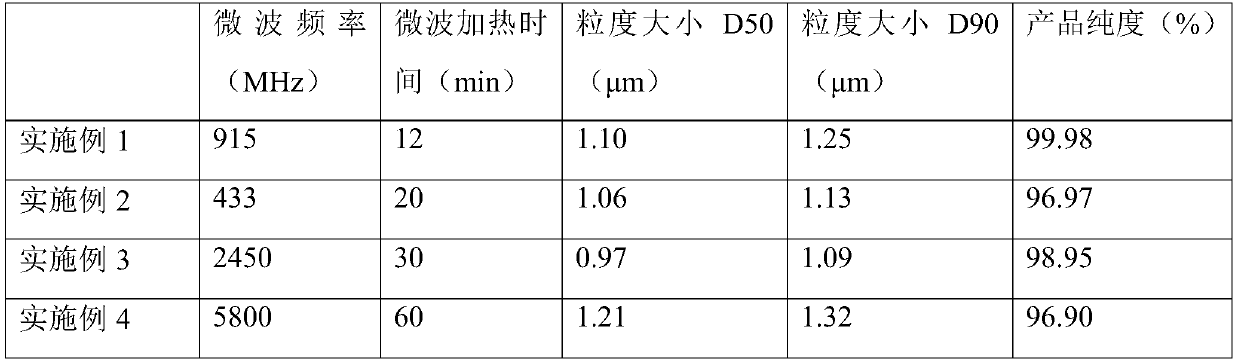

Examples

Embodiment 1

[0026] A microwave preparation method of lanthanum cerium terbium oxide fluorescent powder, comprising the following steps,

[0027] (1) The lanthanum cerium terbium salt solution is mixed to obtain a raw material solution, the ion concentration ratio in the raw material solution is lanthanum: cerium: terbium = 5:2.5:2, and the concentration of rare earth metal ions is 0.8mol / L; The ratio of 1:4 is dissolved and mixed with water evenly as a precipitant;

[0028] (2) Use water as the bottom liquid, preheat the raw material liquid, precipitant, and bottom liquid to 55°C before use, and add PAMMA polyacrylate in the bottom liquid as a surface additive;

[0029] (3) Under the action of ultrasonic waves and stirring, the raw material liquid and the precipitant are added dropwise to the bottom liquid twice respectively, and the ratio of the added substances of the raw material liquid and the precipitant is raw material liquid: precipitant = 1:2; When adding the raw material solutio...

Embodiment 2

[0032] A microwave preparation method of lanthanum cerium terbium oxide fluorescent powder, comprising the following steps,

[0033] (1) The lanthanum cerium terbium salt solution is mixed to obtain a raw material solution, the ion concentration ratio in the raw material solution is lanthanum: cerium: terbium = 5:2:2, and the rare earth metal ion concentration is 0.7mol / L; Dissolve and mix with water at a ratio of 1:3 as a precipitant;

[0034] (2) Use ethanol as the base solution, preheat the raw material solution, precipitant, and base solution to 50°C before use, and add SDBS sodium dodecylbenzenesulfonate to the base solution as a surface additive;

[0035] (3) Under ultrasonic action and stirring, the raw material solution and the precipitant are added dropwise to the bottom solution twice respectively, and the ratio of the amount of the added substance between the raw material solution and the precipitant is raw material solution:precipitant=1:2.5; When adding the raw m...

Embodiment 3

[0038] A microwave preparation method of lanthanum cerium terbium oxide fluorescent powder, comprising the following steps,

[0039] (1) Mix the lanthanum, cerium and terbium salt solution to obtain a raw material solution, the ion concentration ratio in the raw material solution is lanthanum: cerium: terbium = 5:3:2, and the concentration of rare earth metal ions is 0.6mol / L; Dissolve and mix with water at a ratio of 1:3 as a precipitant;

[0040] (2) Water and ethanol are used as the bottom liquid, the volume ratio of water and ethanol is water: ethanol = 1:1.5, the raw material liquid, precipitant, and bottom liquid are preheated to 60°C before use, and CTAB sixteen is added to the bottom liquid Alkyltrimethylammonium bromide as a surface additive;

[0041](3) Under the action of ultrasonic waves and stirring, the raw material solution and the precipitating agent are respectively added dropwise to the bottom liquid twice, and the ratio of the amount of substances added bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com