Catalyst for preparing 1,3-propanediol through glycerine hydrogenolysis

A glycerol hydrogenolysis and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problem of high catalyst preparation cost, harsh reaction conditions, etc. The problem of low yield of 1,3-propanediol, etc., achieves the effect of good industrial application prospect, simple preparation process and good catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

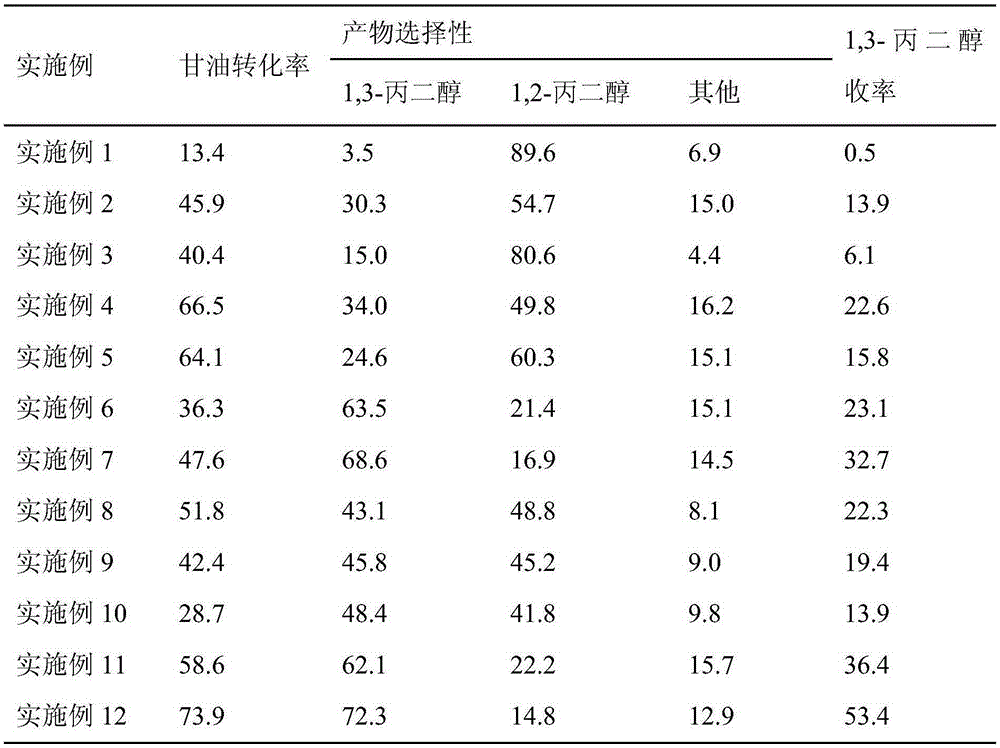

Examples

Embodiment 1

[0020] Dissolve 14.82g of cobalt nitrate and 73.58g of aluminum nitrate in 500mL of deionized water. Dissolve 20 g of anhydrous potassium carbonate in 100 mL of deionized water to prepare a solution with a concentration of 3.6 mol / L. At room temperature, drop the potassium carbonate solution into the metal solution drop by drop until the pH of the mixed solution is 9, continue to stir the reaction, filter after aging at room temperature for 48 hours, wash 5 times with deionized water, and obtain the solid product After drying at 100°C for 24 hours, it was ground into powder. Weigh 0.5g of silicotungstic acid and dissolve it in 30mL of deionized water, stir evenly, then weigh 10g of solid powder and add it to the silicotungstic acid solution, keep stirring at room temperature for 24h, then dry at 100°C for 24h, and finally dry at 400°C The final catalyst was obtained by calcining for 4 hours, grinding, and tableting.

[0021] The glycerol hydrogenolysis reaction is carried ou...

Embodiment 2

[0027] Dissolve 14.82g of cobalt nitrate and 73.58g of aluminum nitrate in 500mL of deionized water. Dissolve 20 g of anhydrous potassium carbonate in 100 mL of deionized water to prepare a solution with a concentration of 3.6 mol / L. At room temperature, drop the potassium carbonate solution into the metal solution drop by drop until the pH of the mixed solution is 9, continue to stir the reaction, filter after aging at room temperature for 48 hours, wash 5 times with deionized water, and obtain the solid product After drying at 100°C for 24 hours, it was ground into powder. Weigh 0.5g of silicotungstic acid and dissolve it in 30mL of deionized water, stir evenly, then weigh 10g of solid powder and add it to the silicotungstic acid solution, keep stirring at room temperature for 24h, then dry at 100°C for 24h, and finally dry at 400°C The final catalyst was obtained by calcining for 4 hours, grinding, and tableting.

[0028] The hydrogenolysis reaction of glycerol is carried...

Embodiment 3

[0030]Dissolve 14.82g of cobalt nitrate and 73.58g of aluminum nitrate in 500mL of deionized water. Dissolve 20 g of anhydrous potassium carbonate in 100 mL of deionized water to prepare a solution with a concentration of 3.6 mol / L. At room temperature, drop the potassium carbonate solution into the metal solution drop by drop until the pH of the mixed solution is 9, continue to stir the reaction, filter after aging at room temperature for 48 hours, wash 5 times with deionized water, and obtain the solid product After drying at 100°C for 24 hours, it was ground into powder. Weigh 0.5g of silicotungstic acid and dissolve it in 30mL of deionized water, stir evenly, then weigh 10g of solid powder and add it to the silicotungstic acid solution, keep stirring at room temperature for 24h, then dry at 100°C for 24h, and finally dry at 400°C The final catalyst was obtained by calcining for 4 hours, grinding, and tableting.

[0031] The glycerol hydrogenolysis reaction is carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com