Graphene oxide and chitosan microsphere and preparation method thereof

A technology of chitosan microspheres and graphene, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of material dissolution and loss, and achieve easy sedimentation, easy sedimentation, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

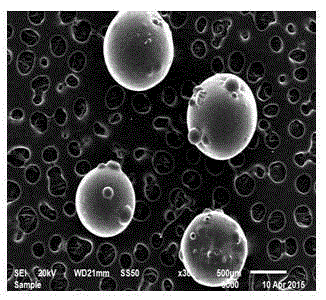

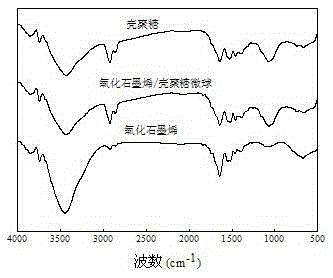

[0025] A graphene oxide / chitosan microsphere and a preparation method thereof. The steps of the preparation method are:

[0026] Step 1. At room temperature, ultrasonically disperse a graphene oxide solution with a mass concentration of 0.01-0.05% to obtain a graphene oxide dispersion; then the mass ratio of chitosan:graphene oxide is 1:(0.01-0.02 ), dissolving chitosan into the graphene oxide dispersion to obtain a graphene oxide / chitosan mixture.

[0027] Step 2, according to the volume ratio of graphene oxide / chitosan mixture: liquid paraffin: span-80 is 1: (1 ~ 1.1): (0.05 ~ 0.08), add to graphene oxide / chitosan mixture Add liquid paraffin and span-80 in turn, stir for 2-4 hours to obtain the graphene oxide / chitosan emulsified mixture; then the volume ratio of graphene oxide / chitosan emulsified mixture: formaldehyde is 1: (0.05~ 0.07), add formaldehyde to graphene oxide / chitosan emulsified mixed solution, continue to stir for 1 ~ 2h, obtain graphene oxide / chitosan emulsi...

Embodiment 2

[0031] A graphene oxide / chitosan microsphere and a preparation method thereof. The steps of the preparation method are:

[0032] Step 1. At room temperature, ultrasonically disperse a graphene oxide solution with a mass concentration of 0.05-0.1% to obtain a graphene oxide dispersion; then press the mass ratio of chitosan:graphene oxide to be 1:(0.02-0.03 ), dissolving chitosan into the graphene oxide dispersion to obtain a graphene oxide / chitosan mixture.

[0033] Step 2, according to the volume ratio of graphene oxide / chitosan mixed solution: liquid paraffin: span-80 is 1: (1.1 ~ 1.2): (0.07 ~ 0.09), add to graphene oxide / chitosan mixed solution Add liquid paraffin and span-80 in turn, stir for 2-4 hours to obtain the graphene oxide / chitosan emulsified mixture; then the volume ratio of graphene oxide / chitosan emulsified mixture: formaldehyde is 1: (0.06~ 0.08), add formaldehyde in graphene oxide / chitosan emulsified mixed solution, continue to stir for 1 ~ 2h, obtain grap...

Embodiment 3

[0037] A graphene oxide / chitosan microsphere and a preparation method thereof. The steps of the preparation method are:

[0038]Step 1. At room temperature, ultrasonically disperse a graphene oxide solution with a mass concentration of 0.1 to 0.15% to obtain a graphene oxide dispersion; then the mass ratio of chitosan: graphene oxide is 1: (0.03 to 0.04 ), dissolving chitosan into the graphene oxide dispersion to obtain a graphene oxide / chitosan mixture.

[0039] Step 2, according to the volume ratio of graphene oxide / chitosan mixture: liquid paraffin: span-80 is 1: (1 ~ 1.1): (0.07 ~ 0.09), add to graphene oxide / chitosan mixture Add liquid paraffin and span-80 in turn, stir for 2-4 hours to obtain the graphene oxide / chitosan emulsified mixture; then the volume ratio of graphene oxide / chitosan emulsified mixture: formaldehyde is 1: (0.07~ 0.09), add formaldehyde to graphene oxide / chitosan emulsified mixed solution, continue to stir for 1 ~ 2h, obtain graphene oxide / chitosan ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com