Lithium battery formed on basis of lithium nickel manganese oxide and lithium titanate and preparation method of lithium battery

A technology of lithium nickel manganese oxide and lithium titanate is applied in the field of lithium batteries based on lithium nickel manganate and lithium titanate and their preparation, so as to achieve the effects of reducing production cost, outstanding cycle life and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

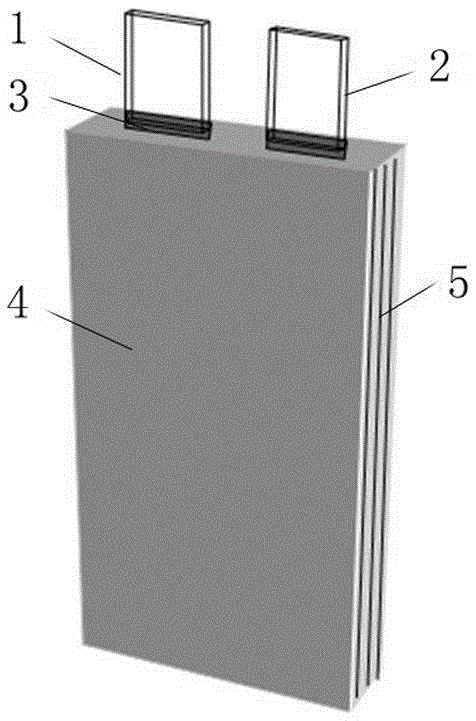

[0052] Embodiment 1: A lithium battery based on lithium nickel manganese oxide and lithium titanate, including an aluminum-plastic film case, a positive tab 1, a negative tab 2, and a tab glue 3, and the aluminum-plastic film case 4 is composed of a cell 5 and an electrolyte, the battery core 5 includes a positive electrode sheet, a separator and a negative electrode sheet; as figure 1 shown;

[0053] The positive electrode includes a current collector aluminum foil, an active material uniformly coated on the surface of the aluminum foil, a binder and a conductive agent;

[0054] The negative electrode includes a current collector copper foil, an active material uniformly coated on the surface of the copper foil, a binder and a conductive agent;

[0055] The positive electrode slurry coating is composed of the following material ratios: Al2O3 coating of lithium nickel manganese oxide: conductive carbon black (SP): carbon nanotubes (CNT): binder polyvinylidene fluoride (PVDF) ...

Embodiment 2

[0069] Embodiment 2: A lithium battery based on lithium nickel manganese oxide and lithium titanate, including an aluminum-plastic film case, a positive tab 1, a negative tab 2, and a tab glue 3, and the aluminum-plastic film case 4 is composed of a cell 5 and an electrolyte, the battery core 5 includes a positive electrode sheet, a separator and a negative electrode sheet; as figure 1 shown;

[0070] The positive electrode includes a current collector aluminum foil, an active material uniformly coated on the surface of the aluminum foil, a binder and a conductive agent;

[0071] The negative electrode includes a current collector copper foil, an active material uniformly coated on the surface of the copper foil, a binder and a conductive agent;

[0072] Positive electrode slurry coating batching and solid content are identical with embodiment case 1;

[0073] The oil-based negative electrode slurry coating is made of the following materials: lithium titanate (Li4Ti5O12): co...

Embodiment 3

[0086] Embodiment 3: A lithium battery based on lithium nickel manganese oxide and lithium titanate, including an aluminum-plastic film case, a positive tab 1, a negative tab 2, and a tab glue 3, and the aluminum-plastic film case 4 is composed of a cell 5 and an electrolyte, the battery core 5 includes a positive electrode sheet, a separator and a negative electrode sheet; as figure 1 shown;

[0087] The positive electrode includes a current collector aluminum foil, an active material uniformly coated on the surface of the aluminum foil, a binder and a conductive agent;

[0088] The negative electrode includes a current collector copper foil, an active material uniformly coated on the surface of the copper foil, a binder and a conductive agent;

[0089] The positive electrode slurry coating is composed of the following material ratios: Al2O3 coating of lithium nickel manganese oxide: conductive carbon black (SP): carbon nanotubes (CNT): binder polyvinylidene fluoride (PVDF) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com