Coating for cement fence and preparation method thereof

A fence and coating technology, applied in the coating and other directions, can solve the problems of poor anti-ultraviolet ability and easy aging, and achieve the effects of improved anti-aging performance and anti-ultraviolet performance, low cost, and strong water and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

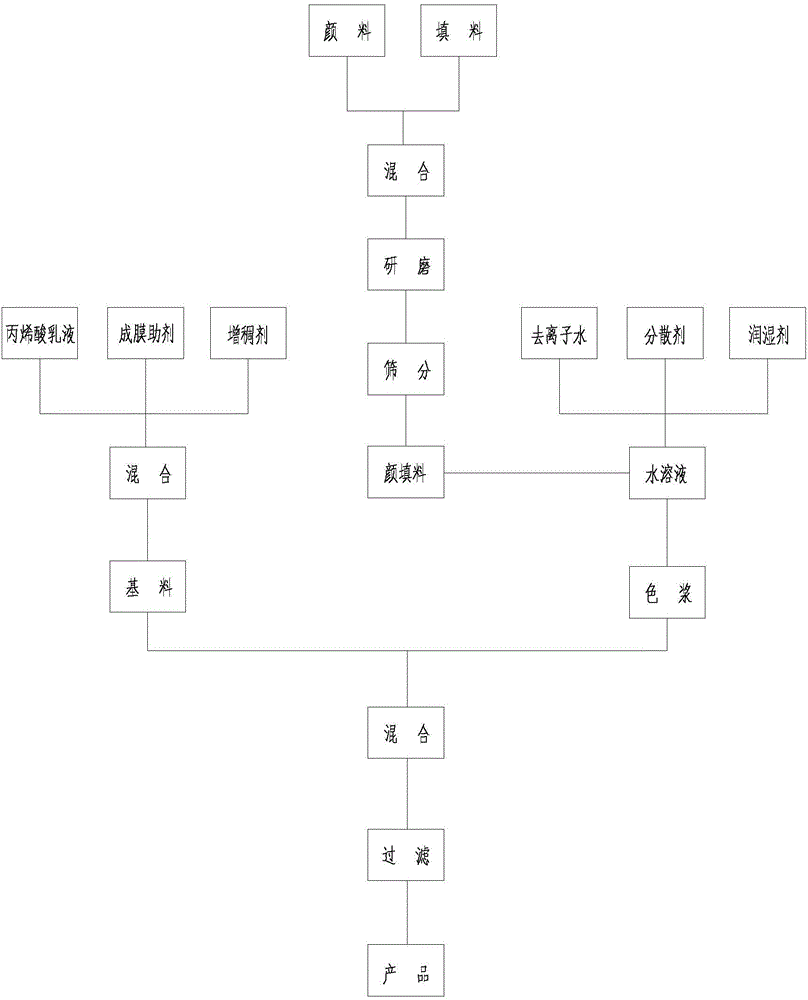

[0029] See attached figure 1 , a kind of preparation method of cement fence paint, comprises the following steps:

[0030] 1) Take acrylic emulsion, film-forming aid and thickener, stir and mix to form base material, set aside;

[0031] 2) Mixing, grinding and sieving pigments and fillers to form pigments and fillers for later use;

[0032]3) Take deionized water, dispersant and wetting agent, stir and mix to form an aqueous solution, and add the pigment and filler obtained in step 2) to the aqueous solution to form a color paste;

[0033] 4) Mix the base material obtained in step 1) with the color paste obtained in step 3), add anti-aging additives and leveling agents to it, and filter to obtain the product.

[0034] Further, in the aqueous solution described in step 3), 0.1-0.5 parts by weight of an antifoaming agent and 0.1-0.5 parts by weight of an antimold and fungicide are also added.

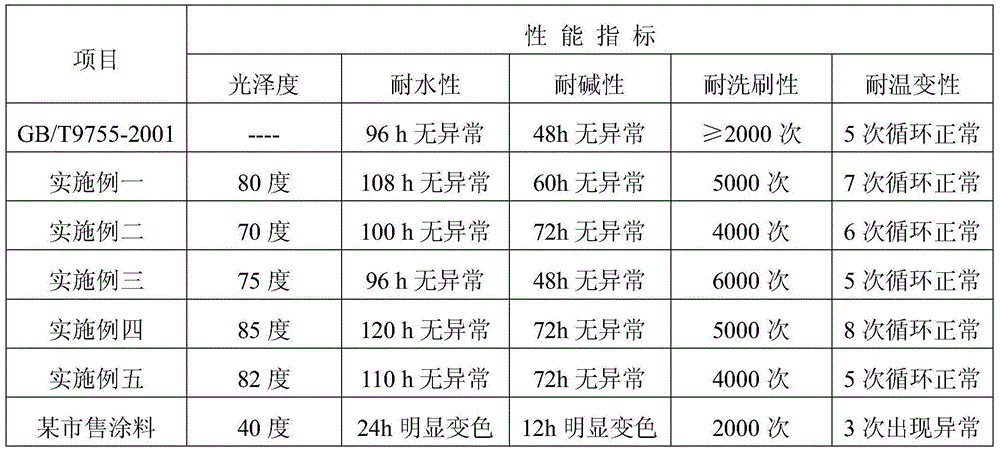

Embodiment 1

[0036] 1) Take 35 parts by weight of acrylic emulsion, 5 parts by weight of film-forming aid and 2 parts by weight of thickener, stir and mix to form a base material, and set aside; wherein, the thickener is an alkali-swellable thickener, and the acrylic emulsion is made of 40wt% of acrylic acid, 45wt% of butyl acrylate, 6wt% of deionized water, 5wt% of emulsifier, 2wt% of acrylamide and 2wt% of organic silicon monomer are polymerized.

[0037] 2) Take pigments and fillers, wherein the weight ratio of pigments and fillers is 1:2, after mixing, grinding, and sieving, the particles below 50 μm form pigments and fillers for subsequent use; wherein, the pigments are inorganic iron oxide pigments, and the fillers are kaolin .

[0038] 3) Take 20 parts by weight of deionized water, 2 parts by weight of dispersant and wetting agent, and 0.5 parts by weight of defoamer, stir and mix to form an aqueous solution, and add 20 parts by weight of pigments and fillers obtained in step 2) to ...

Embodiment 2

[0042] 1) Take 50 parts by weight of acrylic acid emulsion, 3 parts by weight of film-forming aid and 1 part by weight of thickener, stir and mix to form a base material, and set aside; wherein, the acrylic acid emulsion consists of 40 wt% of acrylic acid, 40 wt% of butyl acrylate, deionized It is prepared by polymerizing 10 wt% of water, 3.5 wt% of emulsifier, 3 wt% of acrylamide, 3 wt% of organic silicon monomer and 0.5 wt% of ammonium persulfate.

[0043] 2) Take pigments and fillers, mix, grind and sieve to form pigments and fillers, and set aside.

[0044] 3) Take 10 parts by weight of deionized water, 1 part by weight of dispersant and wetting agent, 0.3 parts by weight of defoamer, and 0.1 part by weight of antiseptic and bactericide, stir and mix to form an aqueous solution, and mix 30 parts by weight of the pigment and filler obtained in step 2) Parts are added to an aqueous solution to form a color paste.

[0045] 4) Mix the base material obtained in step 1) with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com