Inkjet reflective film and preparation process thereof

A reflective film and inkjet technology, applied in optics, optical components, instruments, etc., can solve the problems of reducing the utilization rate of reflective film, limited service life, etc., and achieve the effect of excellent outdoor weather resistance, improved whiteness, and fast drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

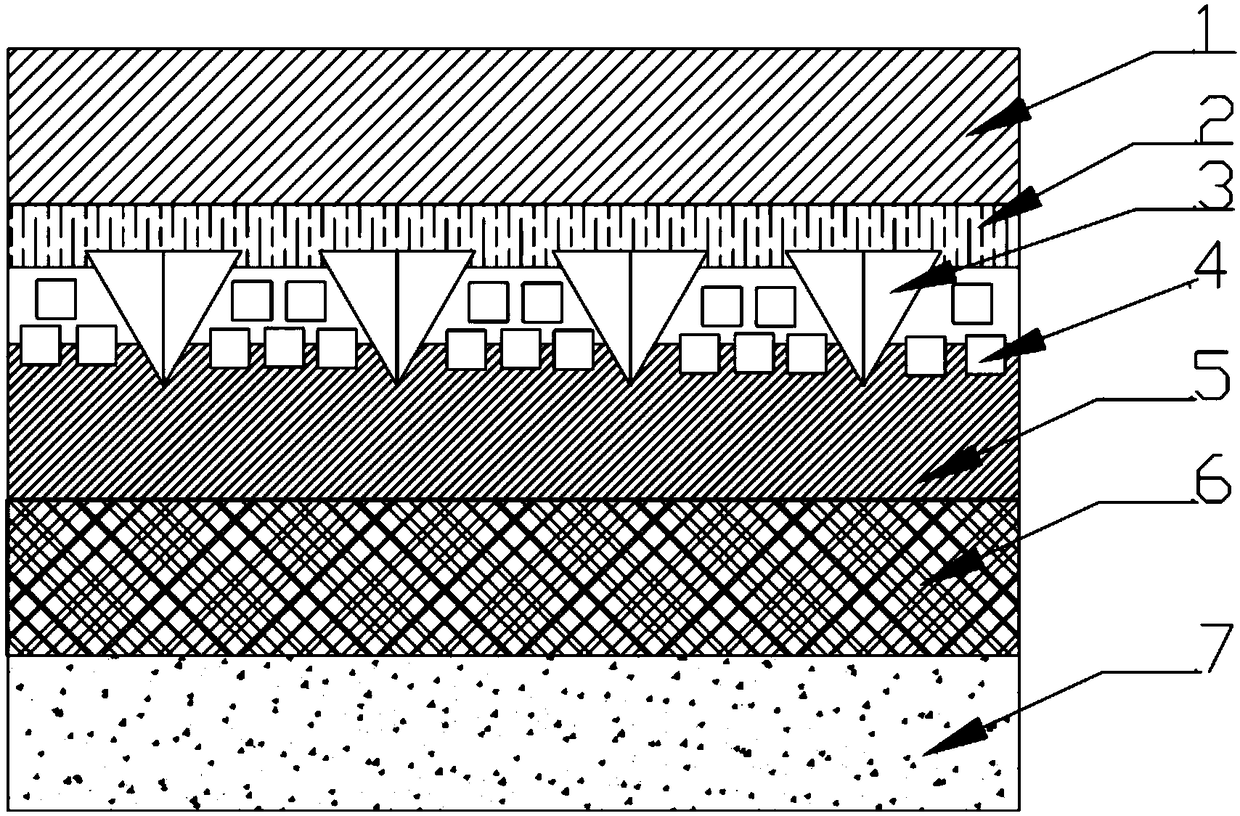

[0036] A preparation process for spray-painted reflective film, comprising the steps of:

[0037] Step 1. Using the PET base film as a carrier, apply a modified ink-absorbing spray-painting layer 1 glue on the carrier with a comma blade coater, and dry it;

[0038] Step 2: Print the adhesive layer 2 glue on the modified ink-absorbing inkjet layer 1 with a micro-gravure printing machine, semi-dry, and stick the microprism crystal powder to the surface of the semi-dried adhesive layer 2 through a plant machine, after sticking Immediately vibrate the roller so that the plane of the microprism crystal powder faces the bonding layer 2, and then continue to dry, and the microprism crystal powder is partially embedded in the bonding layer 2;

[0039] Step 3: Use the PET release film as the carrier, and use a comma blade coater to coat the glue of the white backing layer 5 on the carrier, half-dry, stick the luminescent powder to the surface of the half-dried white backing layer 5 thr...

Embodiment 1

[0045] A preparation process for spray-painted reflective film, comprising the steps of:

[0046] Step 1. Use a PET base film with a thickness of 50 μm and a width of 1270 mm (requires a shrinkage rate of ≤0.2% at 180° C.) as a carrier, and use a comma blade coater to coat the modified ink-absorbing inkjet layer glue (PVC solution system glue, press In terms of mass percentage, it consists of the following components: 22% PVC powder, 50% THF solvent, 20% MIBK solvent, 6% plasticizer, 1% epoxy soybean oil, 0.5% graphene, 0.2% UV ultraviolet absorber, 0.2% light stabilizer, 0.1% viscosity stabilizer), setting knife edge 400μm, 60℃-140℃ oven gradient heating, speed 10m / min, winding tension 1.8KG, dry thickness 50±1μm, residual solvent ≤0.5 %, the coating is uniform in appearance, without bubbles and particles.

[0047]Step 2, print bonding layer glue (80% acrylic resin (50% solid content), 10% ethyl acetate solvent, 9.8% Bayer N-75 curing agent, 0.1% with micro-gravure printer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com