Integrated wastewater treatment device and petrochemical two-level effluent water treatment method

A wastewater treatment, integrated technology, applied in multi-stage water treatment, water/sewage treatment, natural water treatment and other directions, can solve the problems of refractory organic matter, low total nitrogen removal efficiency, etc. The effect of enhancing the oxidative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

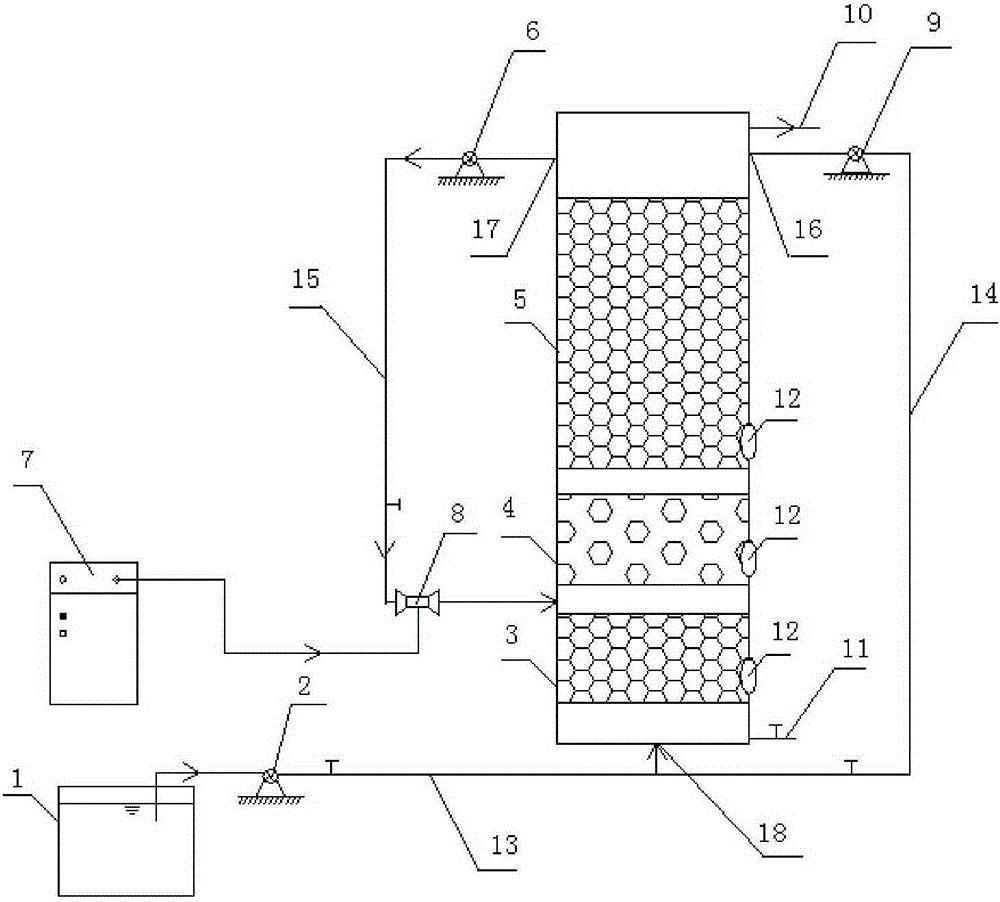

[0026] Such as figure 1 As shown, the integrated wastewater treatment device of the present invention includes a reactor, an ozone generator 7, a water tank 1, a venturi tube 8; wherein the reactor includes a denitrification zone 3, an ozone catalytic oxidation zone 4, and an aeration zone from bottom to top. In the gas biological filter zone 5, a water inlet 18 is provided at the bottom of the denitrification zone 3, and a water outlet 10 is provided at the top; a first reflux port 16 and a second reflux port 17 are provided on the upper part of the reactor; The water inlet 18 is connected to the water tank 1 through a first pipe 13 and is connected to the first return port 16 through a second pipe 14;

[0027] The ozone generator 7 is connected to the Venturi tube 8, the water inlet of the Venturi tube 8 and the second return port 17 are connected by a third pipeline 15, and the water outlet of the Venturi tube 8 is connected to The lower part of the ozone catalytic oxidation ...

Embodiment 2

[0032] The method of using the integrated wastewater treatment device of the present invention to perform petrochemical secondary effluent treatment includes the following steps:

[0033] The waste water in the water tank 1 enters the reactor through the water inlet pump 2, and sequentially passes through the denitrification zone 3, the ozone catalytic oxidation zone 4 and the biological aerated filter zone 5, and flows out from the water outlet 10. At the same time, there are two return lines. One line achieves return flow through the first return port 16, the first return pump 9 and the second pipeline 14. The second line reaches the Venturi tube 8 through the second return port 17, the second return pump 6 and the third pipeline 15, and returns The wastewater enters the lower part of the ozone catalytic oxidation zone 4 after being mixed with the ozone generated by the ozone generator 7 in the venturi tube 8 to realize backflow.

[0034] Preferably, the reflux volume of the ozon...

Embodiment 3

[0036] This embodiment takes the secondary effluent of a typical petrochemical wastewater as the treatment object. The wastewater quality indicators are as follows: COD is between 60 and 120 mg / L, BOD 5 Between 0.95~4mg / L, UV 254 Between 0.6~0.81 / cm, NH 4 + -N concentration is below 2mg / L, TN content is about 20mg / L, pH is between 7-8, SS is between 20-27mg / L, and TP is between 1.0-1.5mg / L. The ozone dosage is 10mg / L, the reflux ratio of the ozone catalytic oxidation unit is 200%, and the reflux ratio of the denitrification unit is 100%. After the above petrochemical wastewater is treated by this process, the effluent index COD is about 50mg / L, NH 4 + -N concentration is below 0.5mg / L, TN content is about 15mg / L.

[0037] The fillers used in the denitrification zone and the BAF zone are all volcanic rocks, and the catalytic oxidation filler used in the ozone catalytic oxidation unit is Al 2 O 3 The catalyst packing, the residence time of wastewater in the whole process HRT is 3h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com